Modular chain newel with standard bearing

A chain, center column technology, used in conveyors, transportation and packaging, escalators, etc., can solve the problem of expensive and inefficient removal and replacement of roller bearings and center column guide rail assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

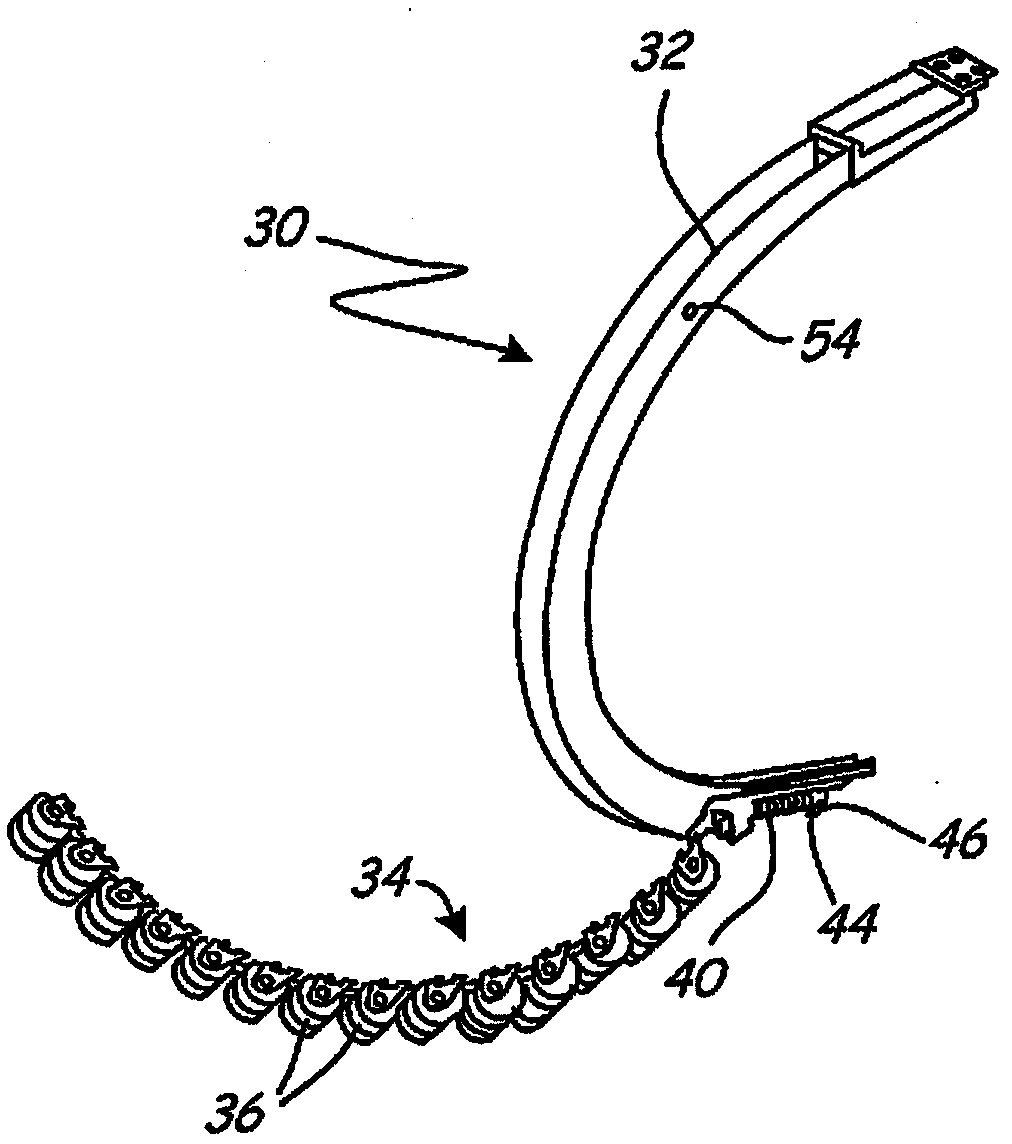

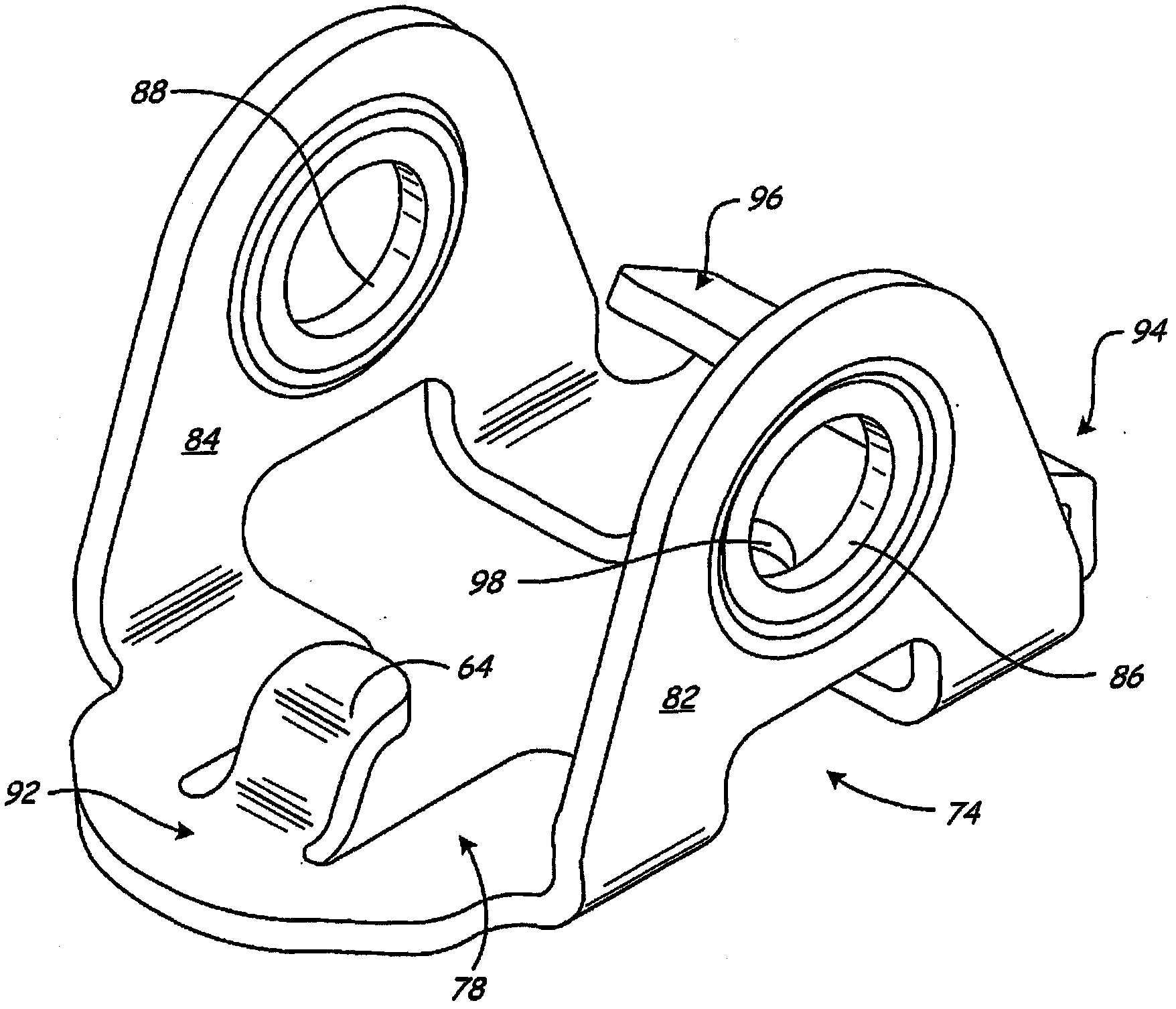

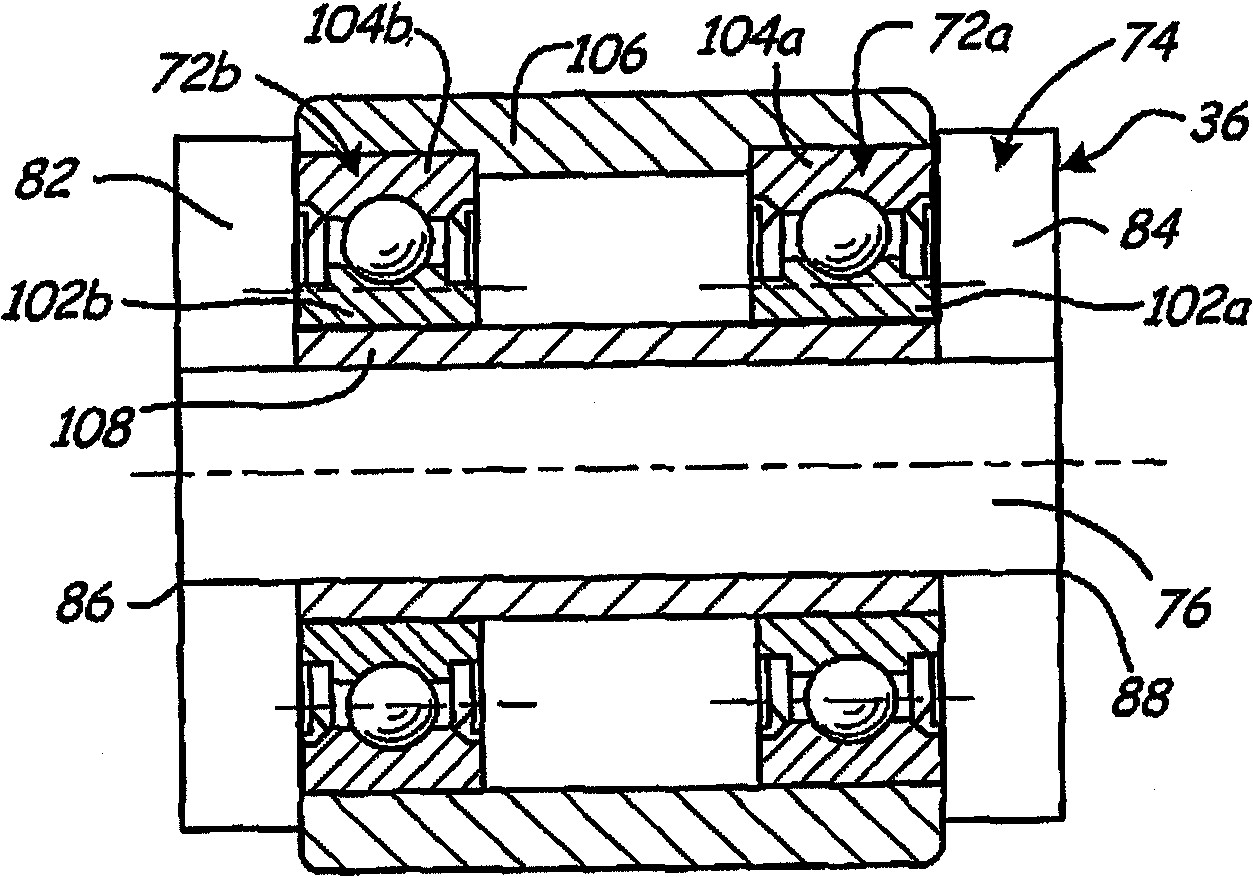

[0015] passenger conveyors, such as figure 1 The escalator 10 shown includes a continuous loop of steps 12 , paired handrails 14 , paired handrails 16 extending along the sides of the steps 12 from a first landing to a second landing, and a drive system 18 . Drive system 18 is configured to drive steps 12 and handrail 14 at a constant speed and in synchronization with each other. The handrails 14 are in sliding engagement with handrail rails 22 disposed on the outer edge of each handrail 16 . Each end of the handrail 16 includes a circular section defining a center post 24 . The center post 24 extends beyond the exposed portion of the steps 12 and provides a turning section for reversing the direction of travel of the handrail 14 for the return trip in a closed cycle through which the handrail 14 travels. Center column 24 comprises roller bearing and center column guide rail assembly 30 ( figure 2 shown) so that the armrest 14 can move around the center post 24.

[0016] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com