Movable pitching telescopic unloading device

A technology of unloading device and telescopic belt conveyor, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of briquette smashing, height difference, high price of stacker and lifter, etc., and achieves low production cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

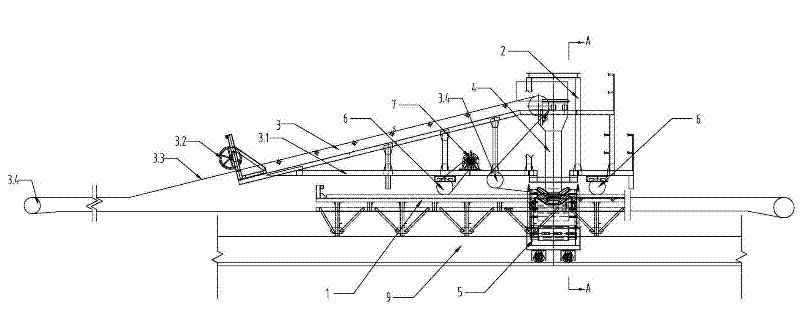

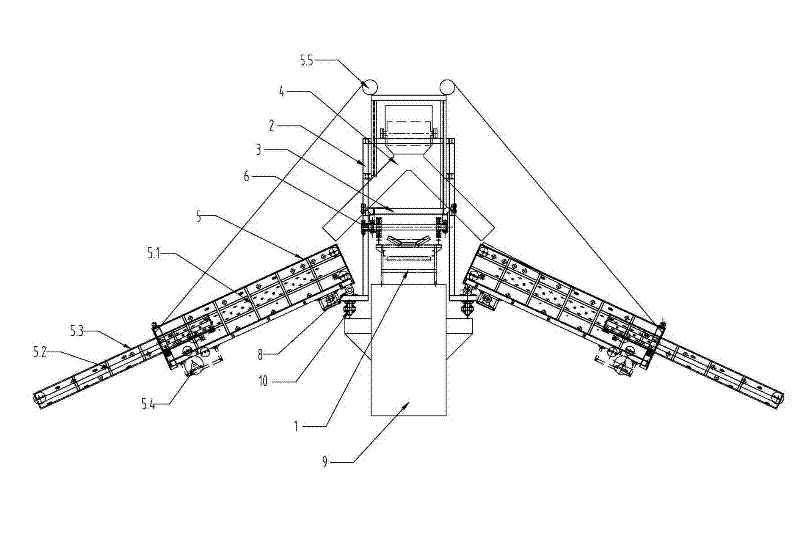

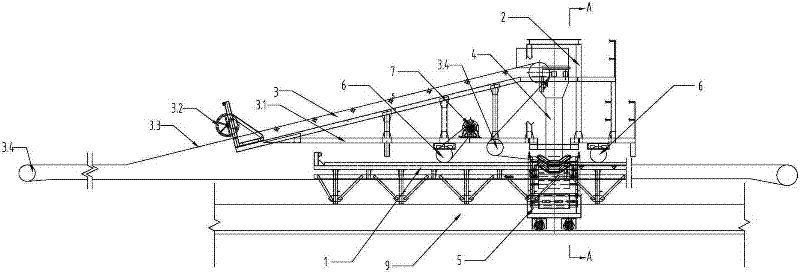

[0010] Such as figure 1 with figure 2 Shown is a mobile pitching telescopic unloading device, which is characterized in that it includes a frame 1, a support 2, a conveyor belt conveyor 3, a herringbone distribution funnel 4 and a pitch telescopic belt conveyor 5; the herringbone distribution funnel 4 is installed on The rear end blanking place of the feeding belt conveyor 3; the bracket 2 is installed on the feeding belt conveyor 3, and the two pitching telescopic belt conveyors 5 are respectively installed on both sides of the bracket 2 through the swing hinge 8 and connected with the outlet of the herringbone distribution funnel 4. The feeding port is corresponding; the conveyor belt conveyor 3 is installed on the frame 1 through the wheels 6; the wheels 6 are driven by the motor 7 installed on the conveyor belt conveyor 3. Conveyor belt machine 3 comprises vehicle frame 3.1, pinch pulley 3.2, conveyor belt 3.3 and guide wheel 3.4. Pitch telescopic belt conveyor 5 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com