Hinged-blade cross-axis turbine for hydroelectric power generation

A technology for hydroelectric generators and turbines, which is used in hydroelectric power generation, reaction engines, water wheels, etc., and can solve the problem that the rotors cannot be closely matched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

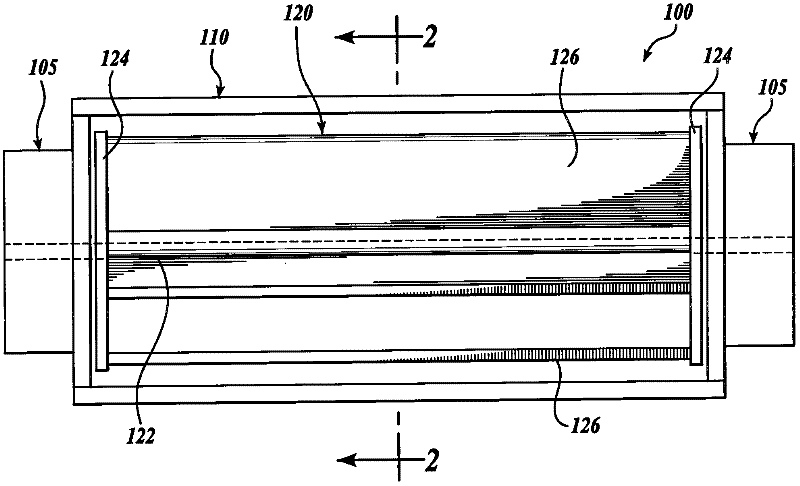

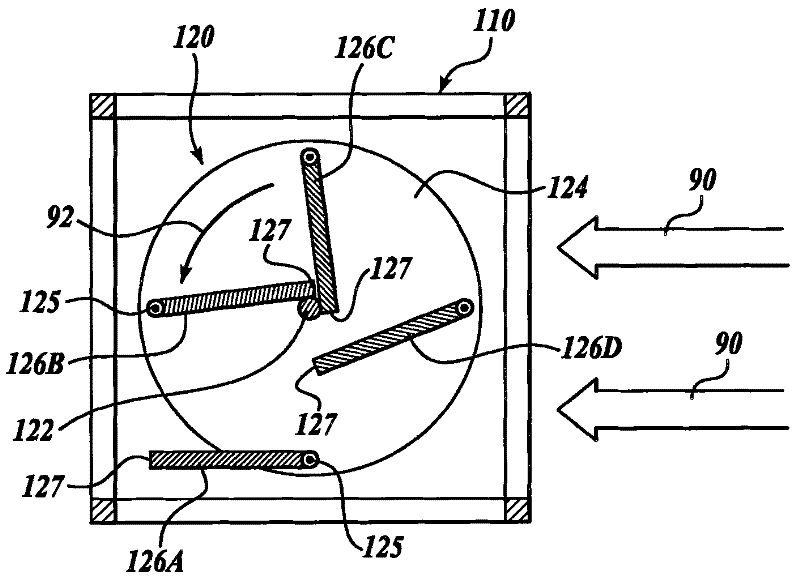

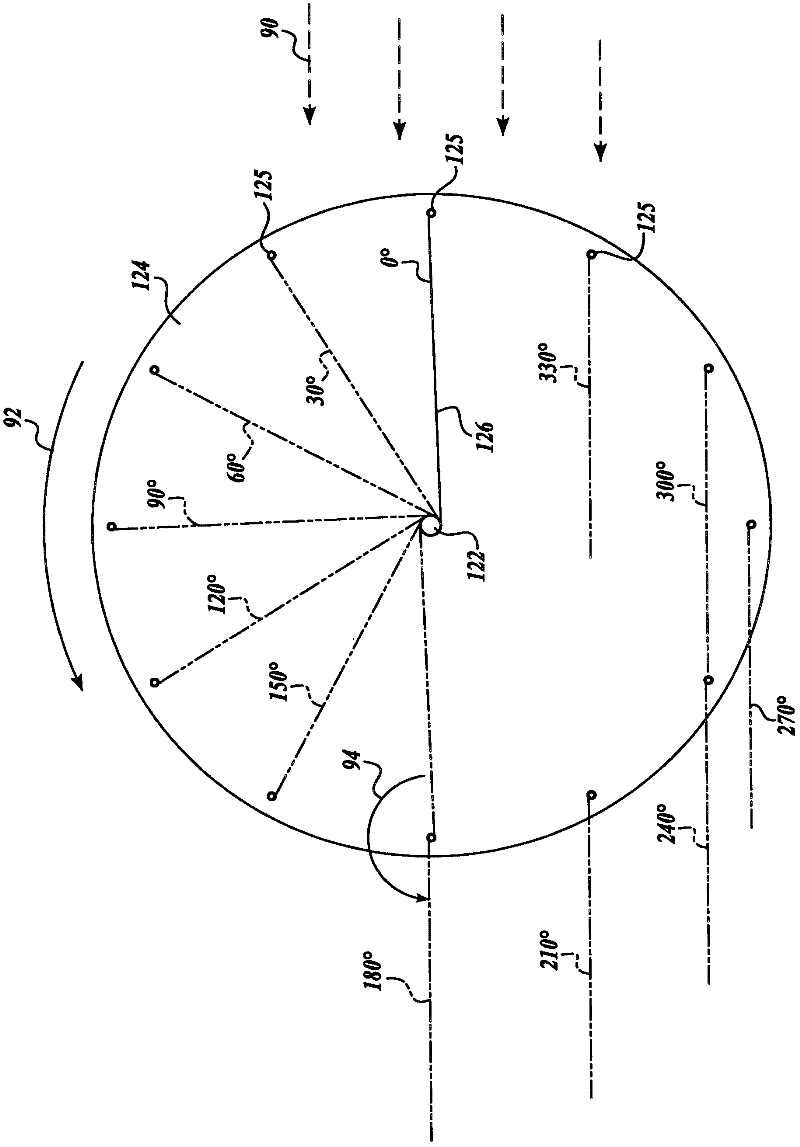

[0026] A hydroelectric generator system 100 according to the present invention is shown in figure 1 middle. In this embodiment, the system 100 includes a water turbine 120 disposed within an optional frame structure 110 . While a simple open (open) rectangular frame structure 110 is illustrated, it is understood that any suitable frame structure may alternatively be used, such as a bifurcated frame including upright supports on either side of the turbine 120 .

[0027] In this embodiment, a pair of generators 105 are attached to either end of the frame structure 110 . Although two generators 105 are shown, it will be appreciated that a different number of generators could alternatively be used. It is believed that in many applications a single generator 105 is preferred.

[0028] New flip-wing TM Turbine 120 is rotatably mounted in frame 110 by a turbine drive shaft 122 configured to driveably engage generator 105 . The turbine 120 includes oppositely disposed support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com