Guide nail structure and nail gun with the same

A nail gun and guide nail technology, applied in the direction of nail staple tools, manufacturing tools, etc., can solve the problems of uneven force on the side of the nail needle and affect the performance, so as to improve work efficiency, avoid nail sticking problems, and improve nails. The effect of uneven needle force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structural features and expected effects of the present invention will be described below with reference to preferred embodiments, which should not be used to limit the protection scope of the present invention.

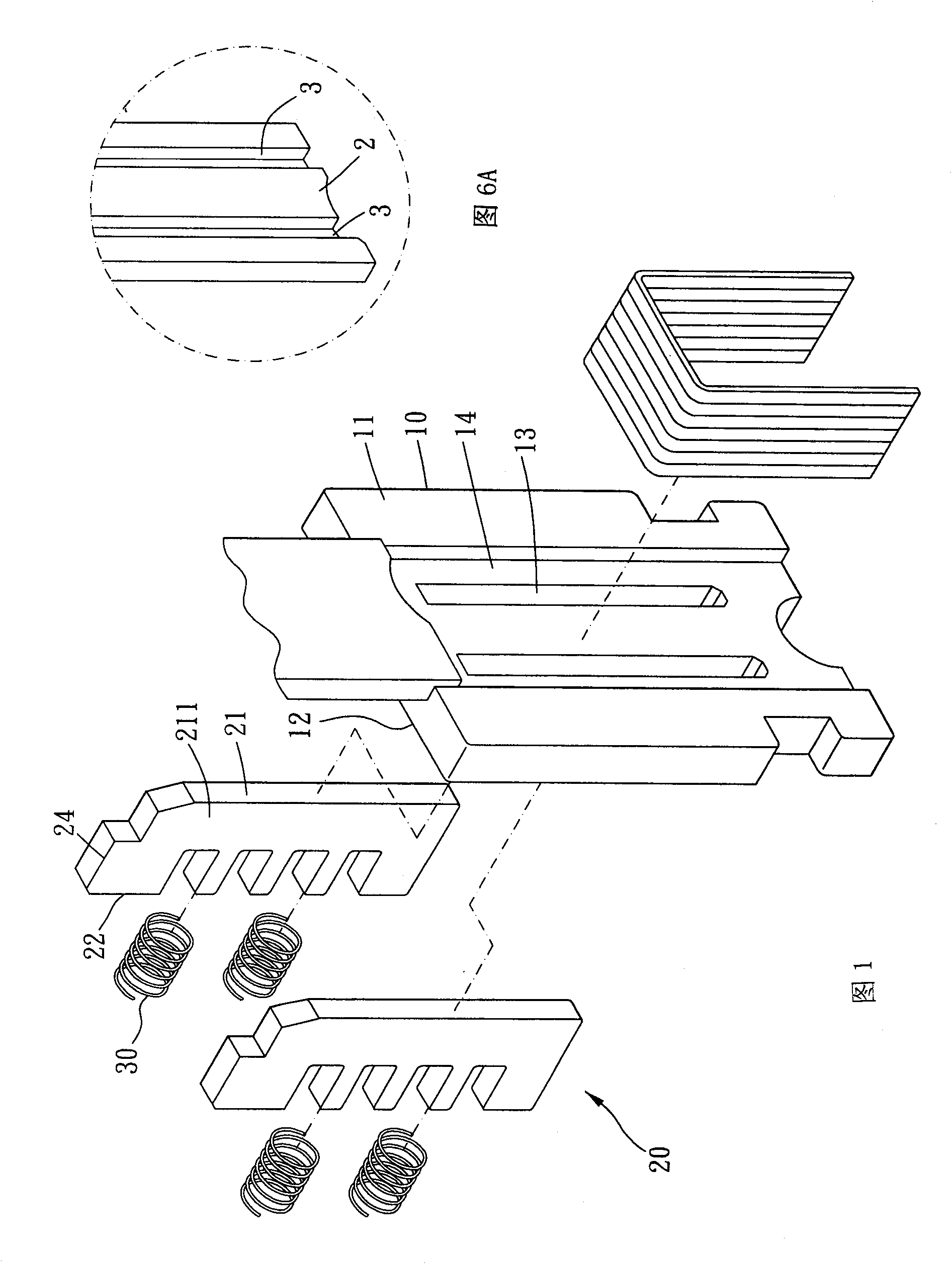

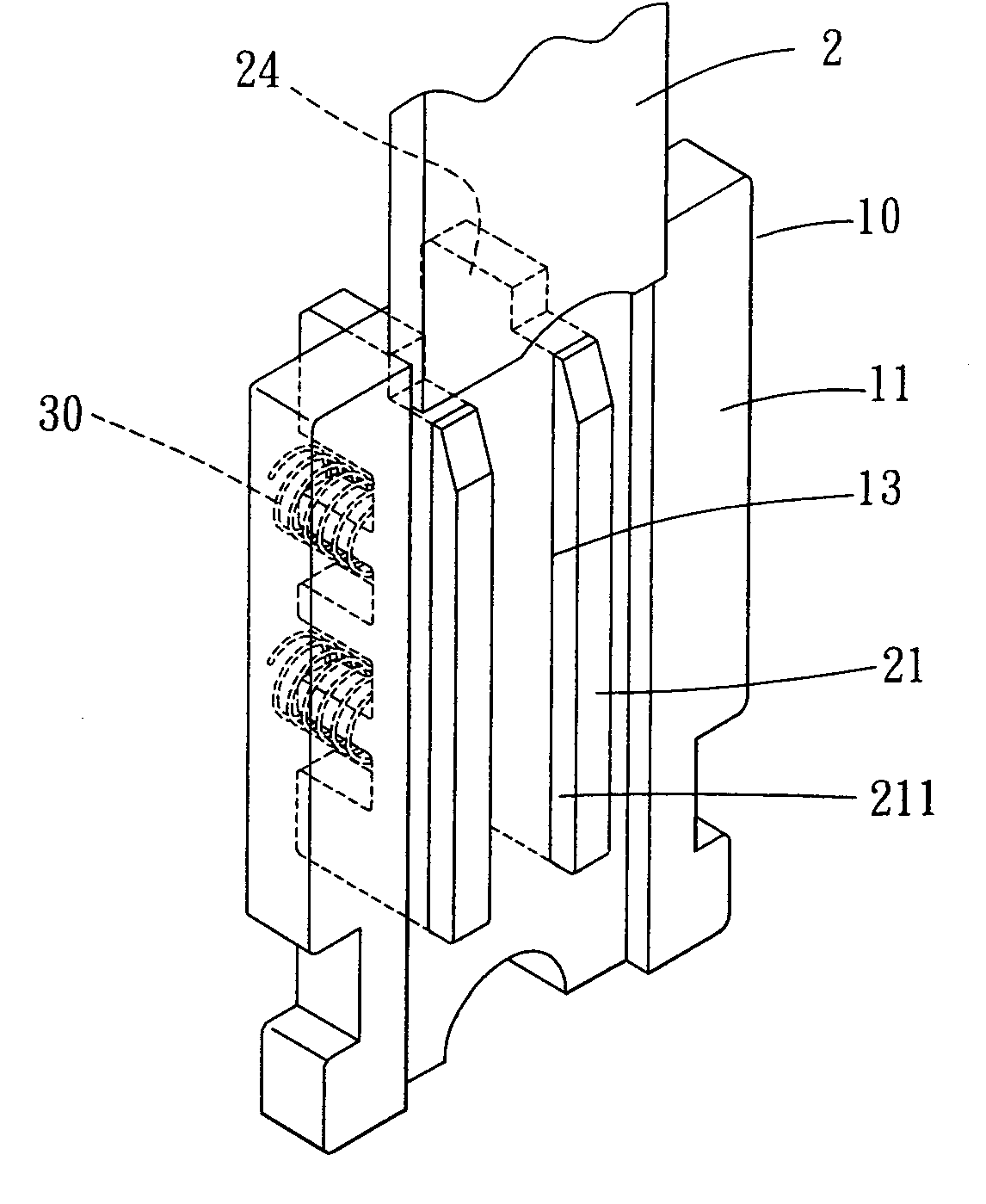

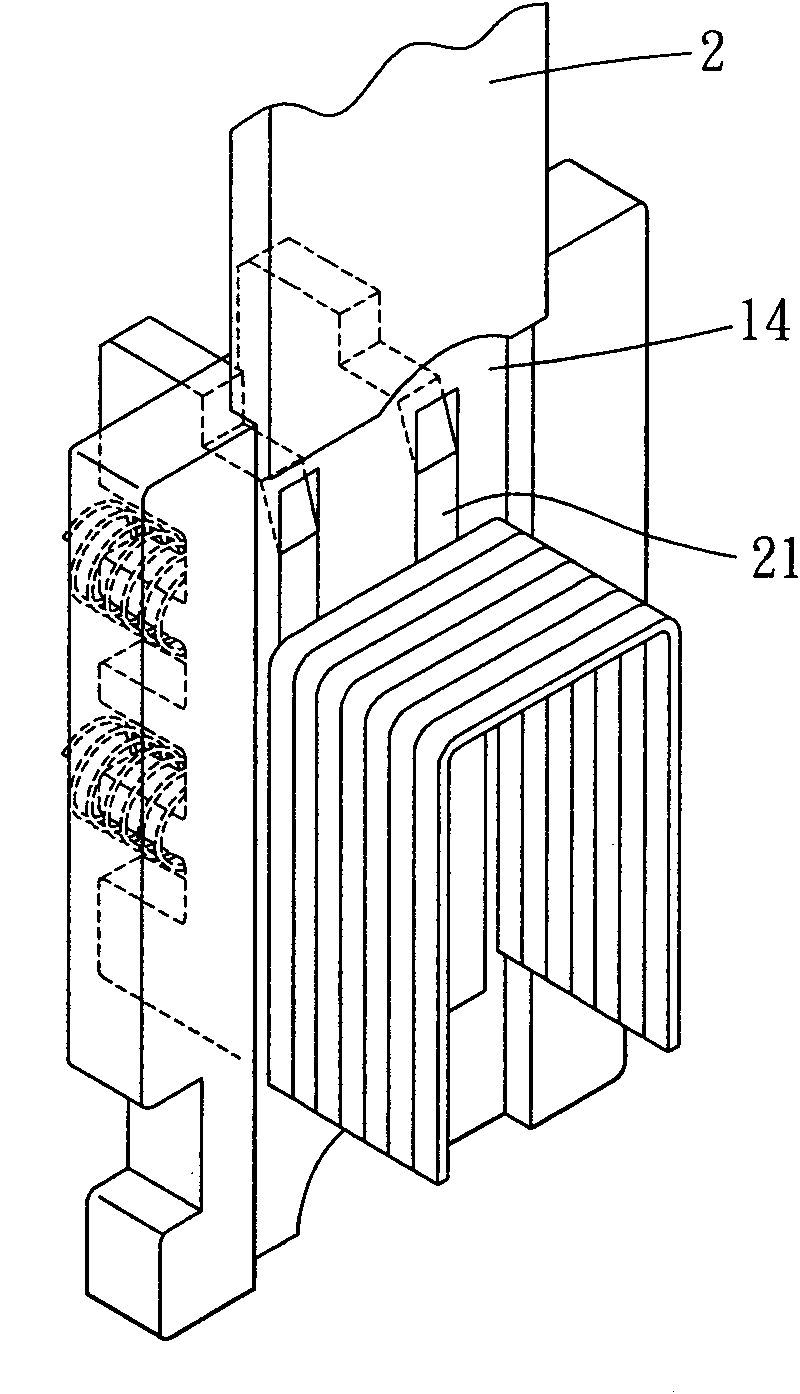

[0032] Please refer to figure 1 and figure 2 . In a preferred embodiment of the present invention, the nail guide structure is provided in a nail gun with a nail rail, and the nail guide structure is provided in front of the nail rail, and the nail guide structure includes a guide plate 10, at least A support piece 20 and a pushing means.

[0033] The guide plate 10 is vertically arranged in front of the nail rail, the guide plate 10 has a first surface 11 and a second surface 12 opposite to the first surface 11, the first surface 11 of the guide plate faces the nail rail, And the guide plate 10 is provided with at least one vertical through groove 13 (in this embodiment, two vertical through grooves are provided), and the through groove 13 runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com