Clamping device and polishing positioning device

A technology of a clamping device and a positioning device, applied in the field of rail grinding, can solve problems such as low efficiency, poor grinding effect, and inability to achieve wave-shaped wear repair, and achieve the effect of realizing grinding and repairing and increasing the grinding operation plane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

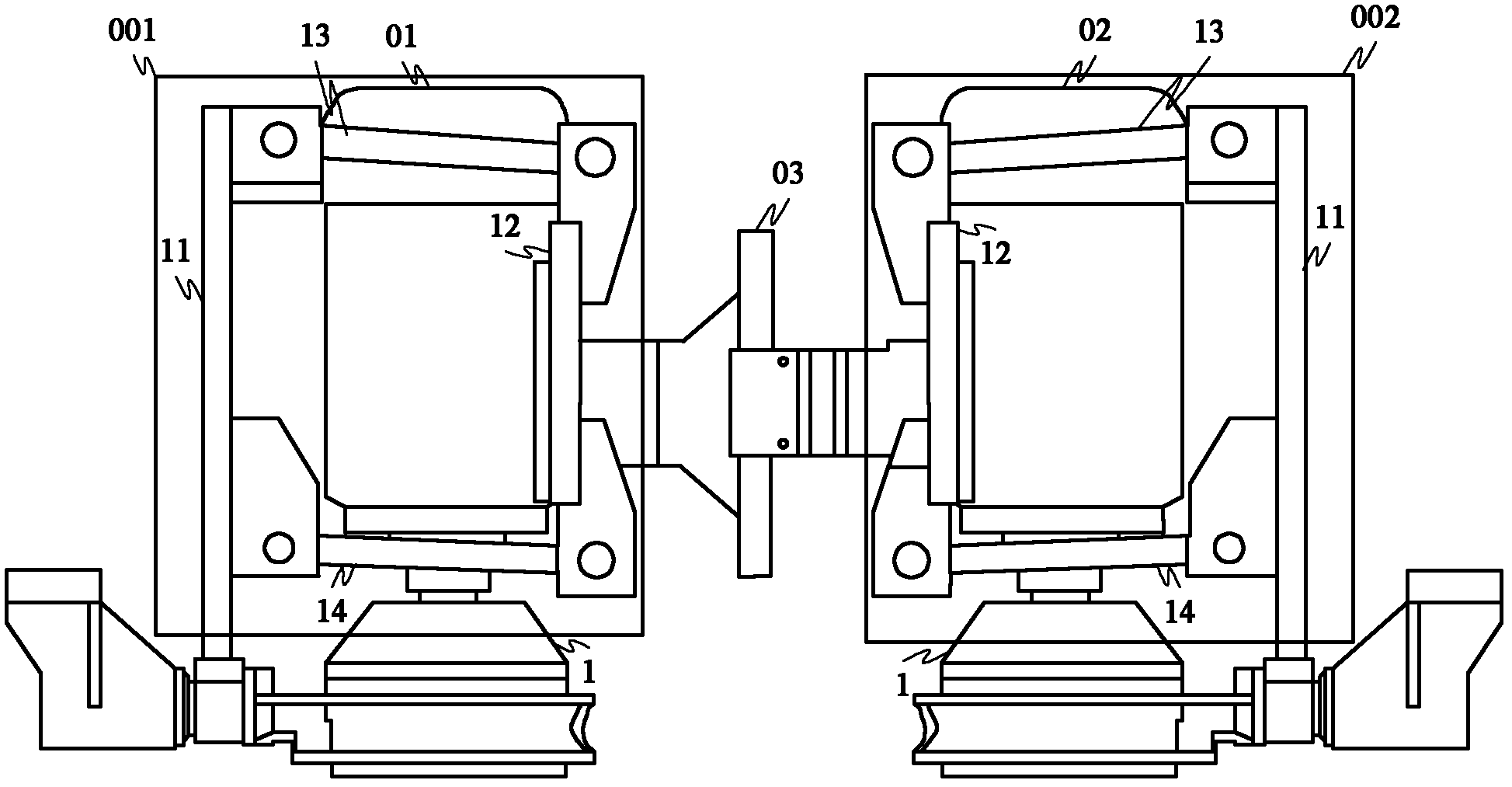

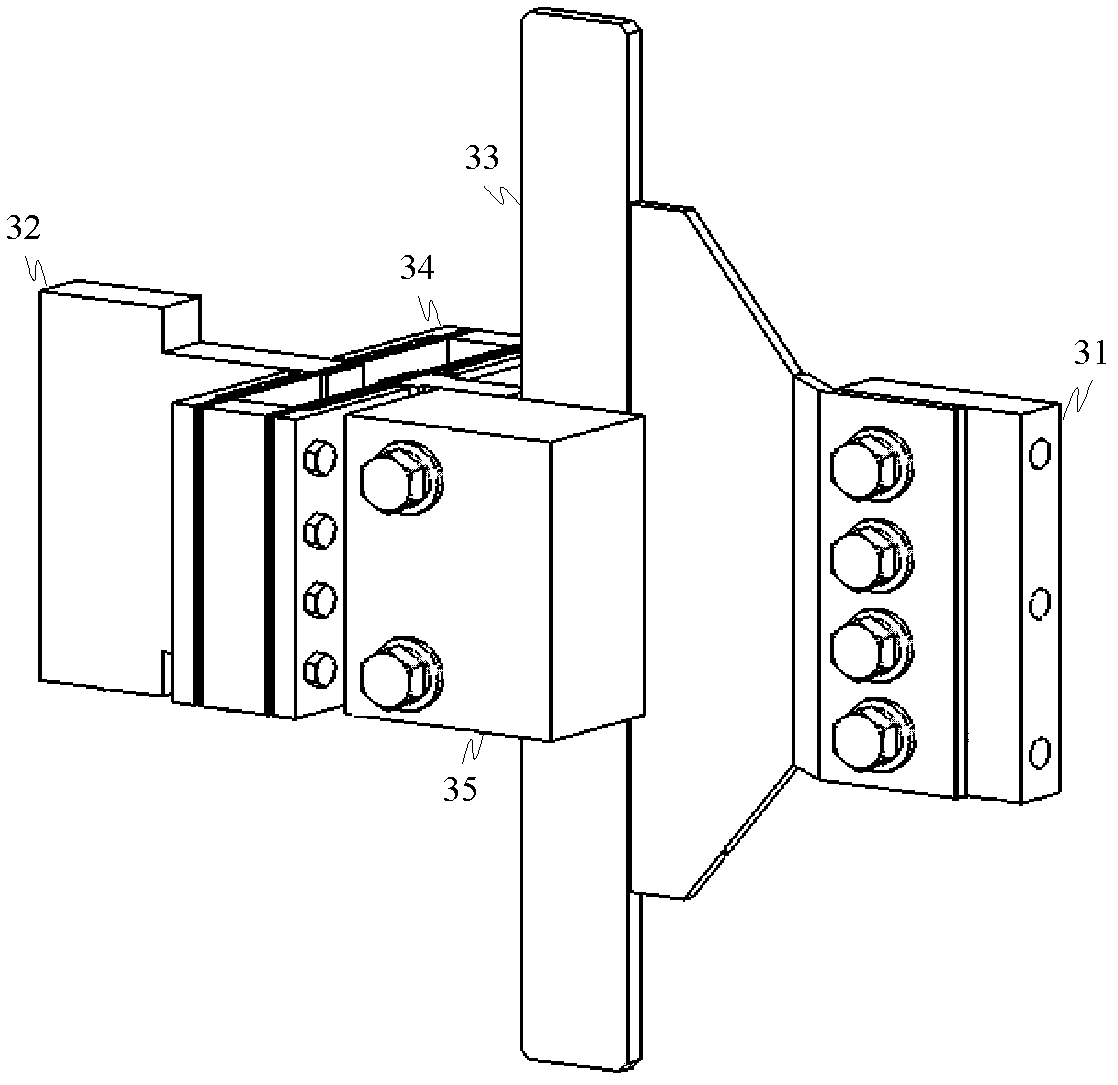

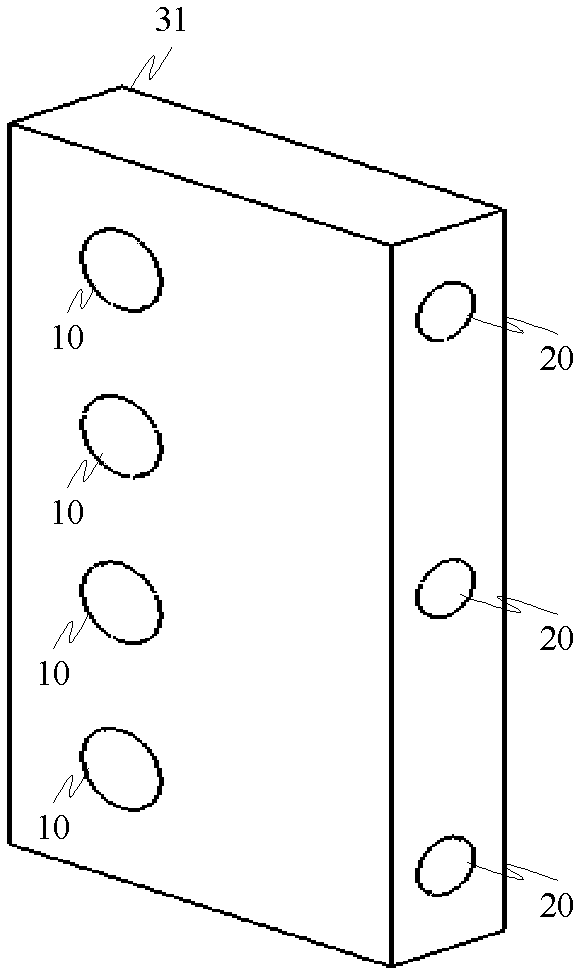

[0043] Such as figure 1 As shown, the grinding positioning device of the present invention includes a first translation mechanism 001 connected to the first grinding device 01, a second translation mechanism 002 connected to the second grinding device 02, and a second translation mechanism 001 connected to the grinding device. The clamping device 03 of the two translation mechanisms 002, in this specific embodiment, the first translation mechanism 001 and the second translation mechanism 002 are parallelogram mechanisms, and the first grinding device 01 and the second grinding device 02 are all formed by the parallelogram mechanism. It is composed of a motor 1 with a grinding wheel, wherein the motor 1 with a grinding wheel is installed in a parallelogram mechanism, and the parallelogram mechanism includes a first vertical rod 11 arranged in parallel, a second vertical rod 12 and a first vertical rod 12 arranged in parallel. Upper cross bar 13 and lower cross bar 14 between up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com