Optoelectronic compound optical cable joint closure and electric cable installation method

An optical cable splice box, photoelectric composite technology, applied in the direction of cable terminal, fiber mechanical structure, etc., can solve problems such as waste, and achieve the effect of solving the difficulty of power extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention are described with reference to the above drawings.

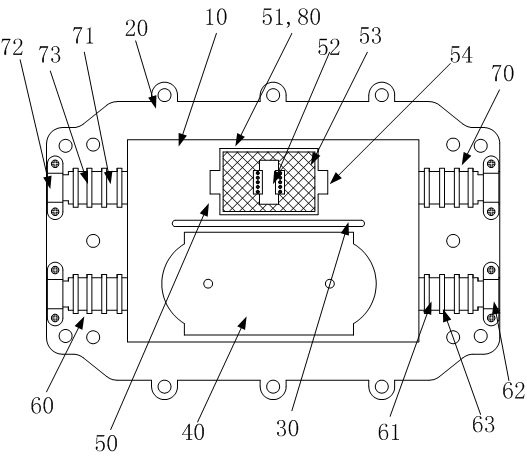

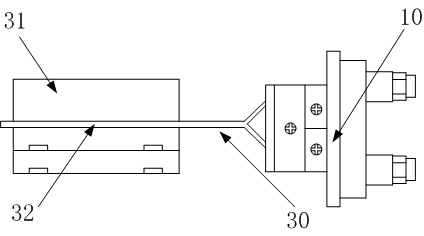

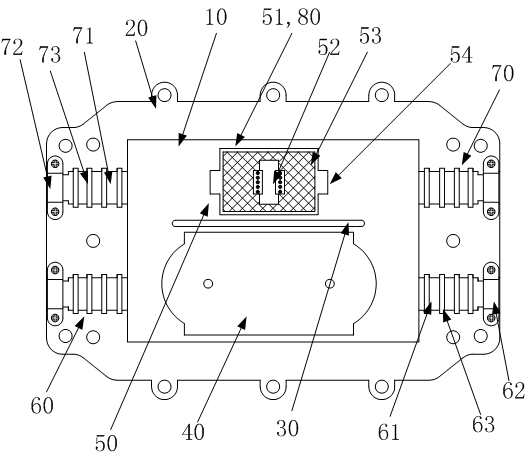

[0011] Depend on figure 1 with figure 2 As can be seen in the figure, this photoelectric composite optical cable splice box includes an upper cover 10 and a bottom box 20 fastened with the upper cover 10, and a bottom box 20 fixed to the bottom box 20 is arranged in the hollow space formed by the fastening of the upper cover 10 and the bottom box 20. The photoelectric isolation board 30 on the top, the optical cable fusion module 40 and the cable joint module 50 fixed on the photoelectric isolation board 30 also include an optical cable channel 60 and a cable channel 70 arranged on the upper cover 10, and the optical cable channel 60 communicates with the optical cable The welding module 40 , the cable channel 70 is connected to the cable joint module 50 . In the present invention, the connection of the optical cable and the cable is concentrated in one photoelectric c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap