Double lumen tubing with improved kinking resistance

A pipe and tubular wall technology, applied in the field of double-cavity pipes, can solve problems such as complex manufacturing costs, and achieve the effects of improving kink resistance, easy and economical manufacturing, and high kink resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The double lumen tubing according to the invention is designed for use as a catheter and can be used with any catheter device in which a double lumen catheter is required.

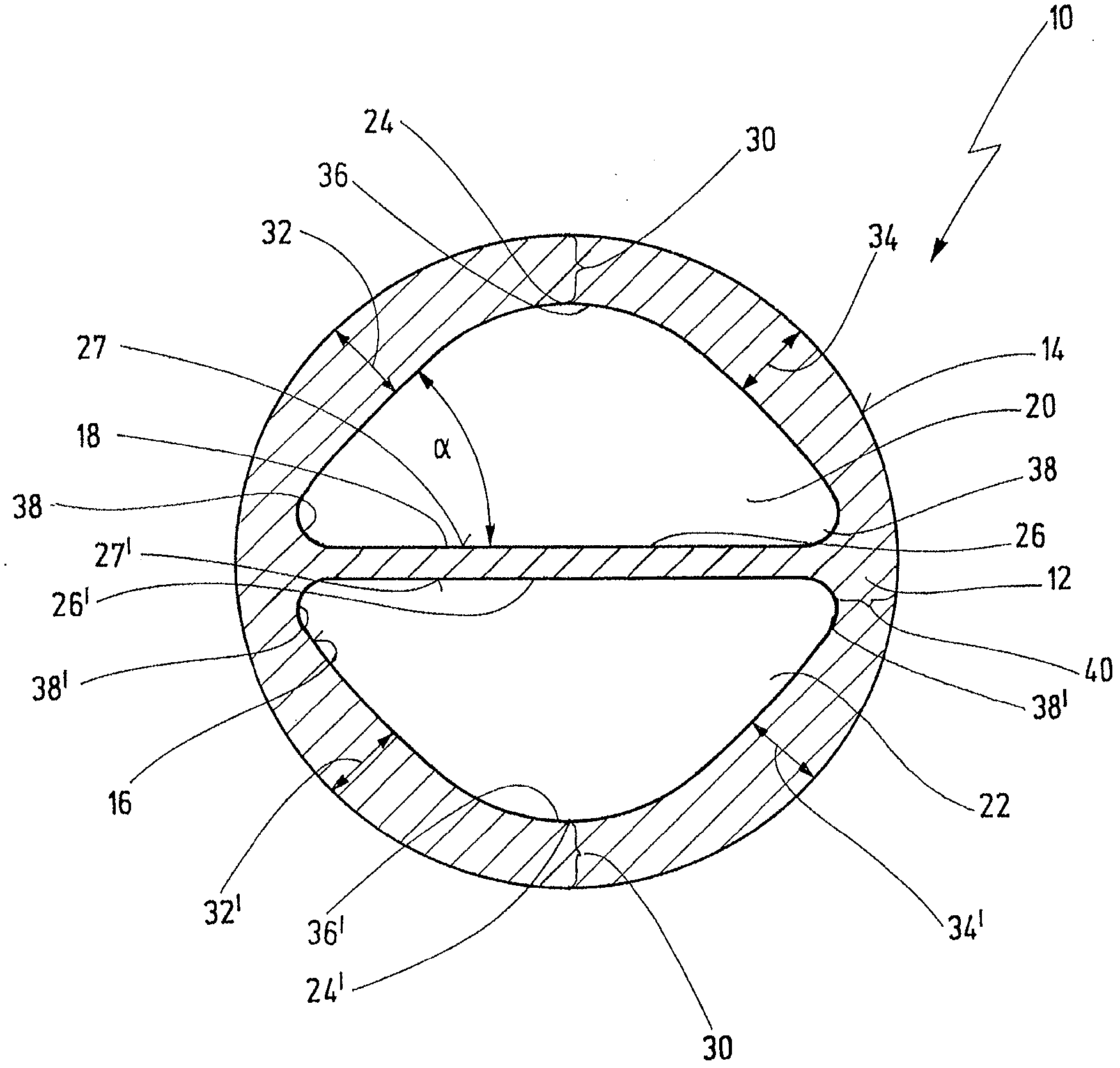

[0044] exist figure 1 The reference number 10 in the figure shows a first preferred embodiment according to the invention. Dual lumen tubing 10 includes a tubular wall 12 having an outer surface 14 and an inner surface 16 . Duct 10 also includes an interior or partition wall 18 that divides the lumen of duct 10 into two lumens: a first lumen 20 and a second lumen 22 . Thus, each of lumens 20 and 22 is defined by inner surface 16 of tubular wall 12 and inner (separator) wall 18 .

[0045] The cross-sectional area of each of the cavities 20, 22 includes an arcuate portion 24, 24' and a substantially planar portion 26, 26' opposite the corresponding arcuate portion 24, 24', the planar portion 26, 26' being defined by the inner wall 18. Surfaces 27 , 27 ′ are defined, and arcs 24 , 24 ′ are defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com