Contactor with contact locking mechanism

A contactor and locking technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of high cost, low reliability, and large space occupation, and achieve simple structure, practicality and reliability, and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

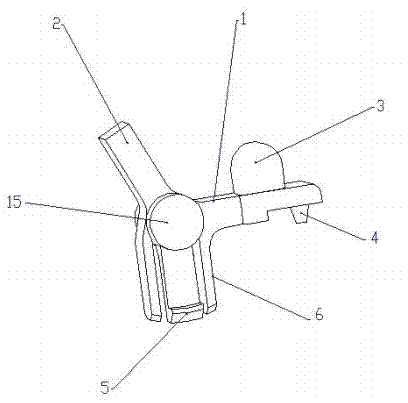

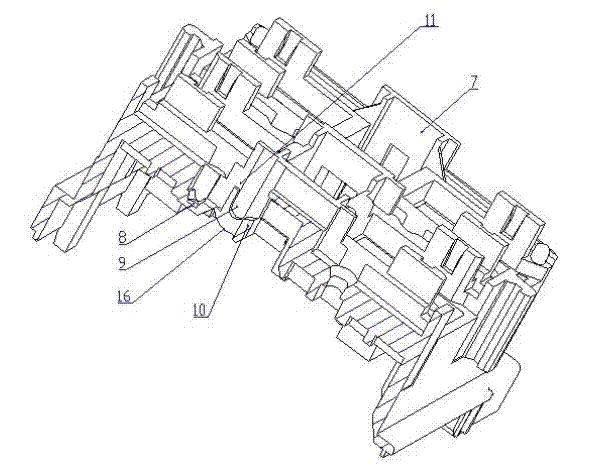

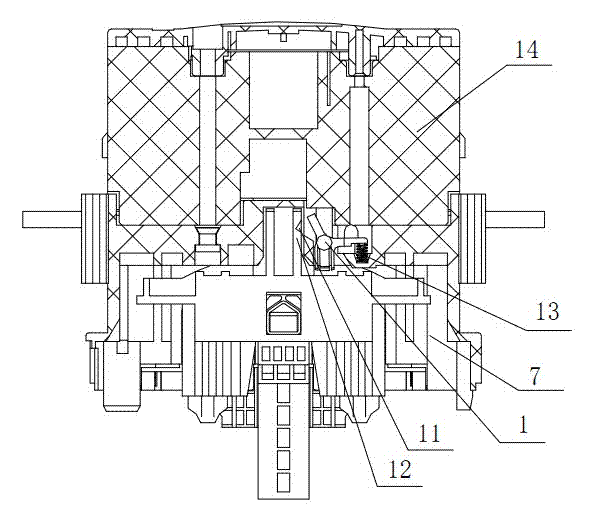

[0018] Refer to attached Figure 1-4 , a contactor with a contact locking mechanism, including a base 7, an arc extinguishing chamber 14 detachable from the base 7, a contact support 12 and a locking mechanism are installed on the base 7, The contact support 12 can be locked by a locking mechanism after the arc extinguishing chamber 7 is removed, and the locking mechanism includes a locking element 1, which is rotatably installed in the base 7, the The base 7 is provided with a stop wall 10 that cooperates with the lower arm 6 of the locking element 1 to limit the movement of the locking element 1; The upper arm 2, the side arm of the locking element 1 is connected with a spring 13 to drive it to rotate, and the side arm of the locking element 1 is provided with a second arm that cooperates with the arc extinguishing chamber 14 to separate the upper arm 2 from the contact support 12 a boss 3 .

[0019] One end of the spring 13 is connected to the first spring seat 4 on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap