Device for cleaning a functional surface for guiding or treating a material web

A technology of working surface and material width, applied in applications, household utensils, brushes, etc., can solve problems such as misalignment, adjustment ring offset, and harsh operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

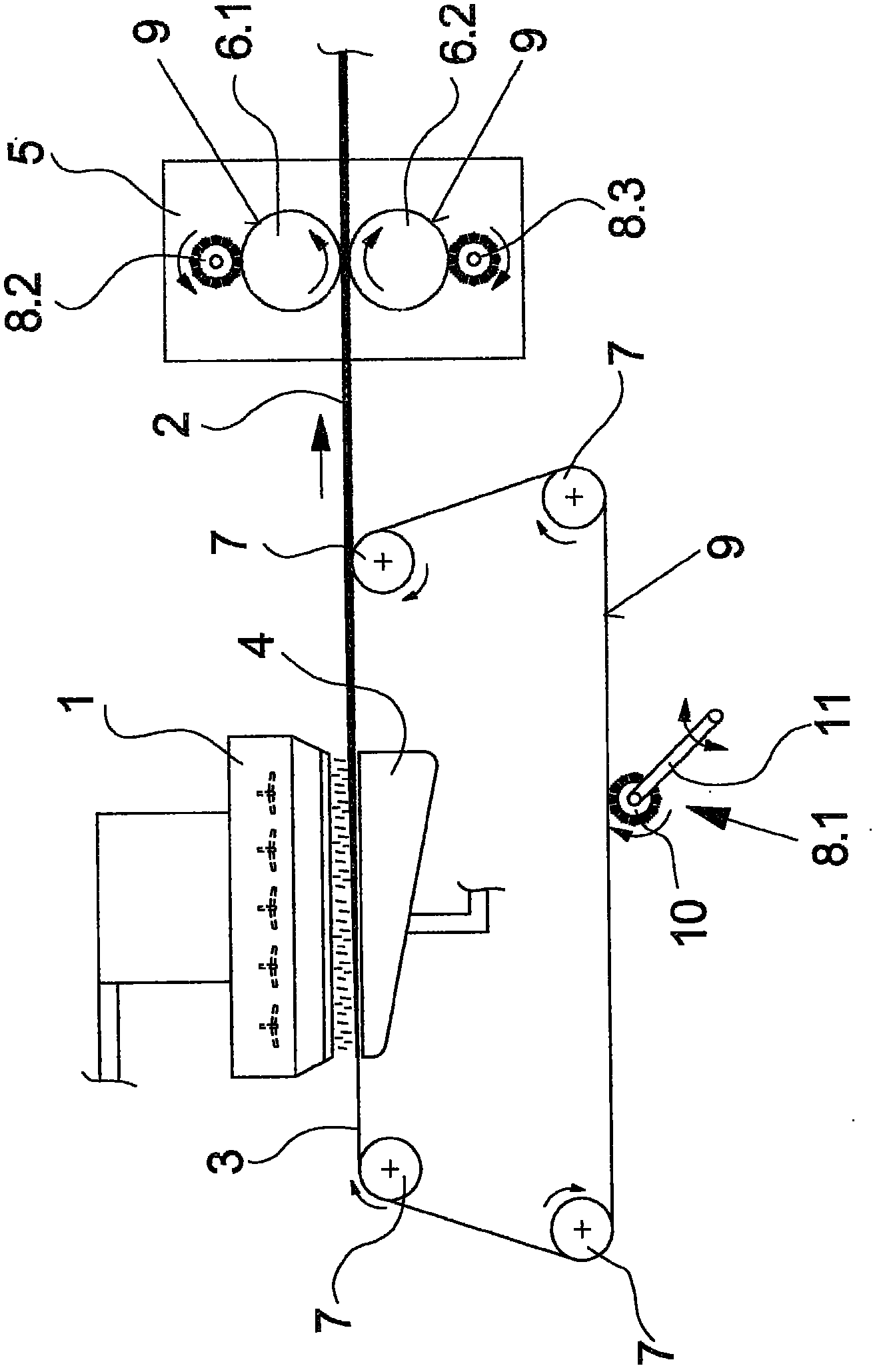

[0032] figure 1 shows an apparatus for producing a nonwoven web, for example as it is used in an air-flow process. Such a device has a plurality of working surfaces which are always cleaned by the device according to the invention. figure 1 Only a small part of the plant for the manufacture and processing of nonwoven webs is shown in . A nonwoven web 2 composed of staple fiber segments is produced on the working surface of the deposition belt 3 . To this end, the deposit belt 3 is assigned a forming station through which the fiber segments are deposited onto the deposit belt 3 . The forming station 1 is assigned a suction device 4 on the underside of the deposit belt 3 , which is continuously driven and guided over guide rollers 7 . The surface of the deposit belt 3 forms a working surface 9 which is cleaned by means of the device according to the invention. For this purpose, a cleaning device 8.1 is shown. The cleaning device 8.1 has a roller carrier 11 on which the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com