Cutter sharpening device of gun drill

A gun drilling and sharpening technology, which is applied to drilling tool accessories, drilling/drilling equipment, boring machine/drilling machine parts, etc. It can solve the problems that the flank surface cannot be ground into a helical surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

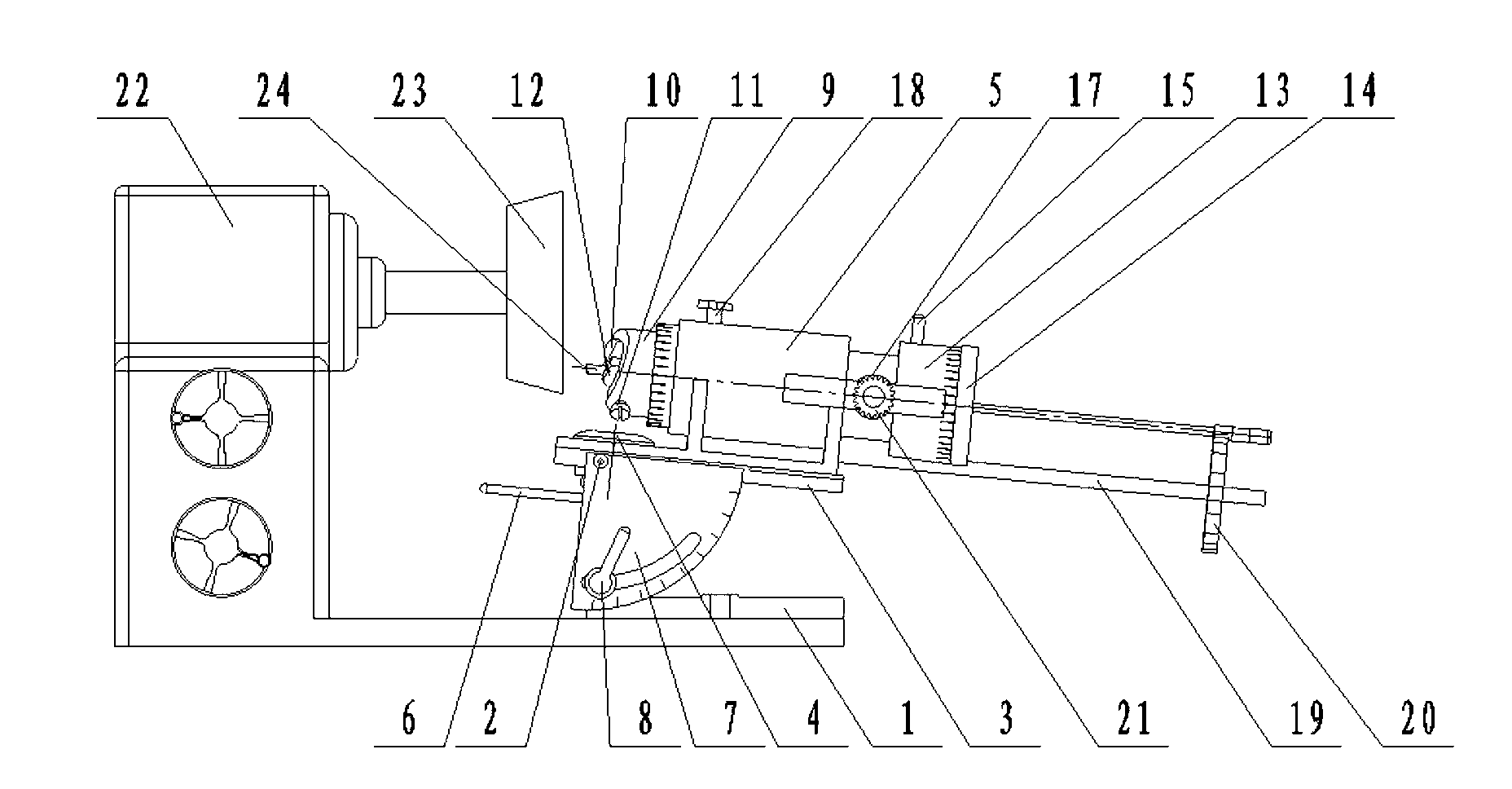

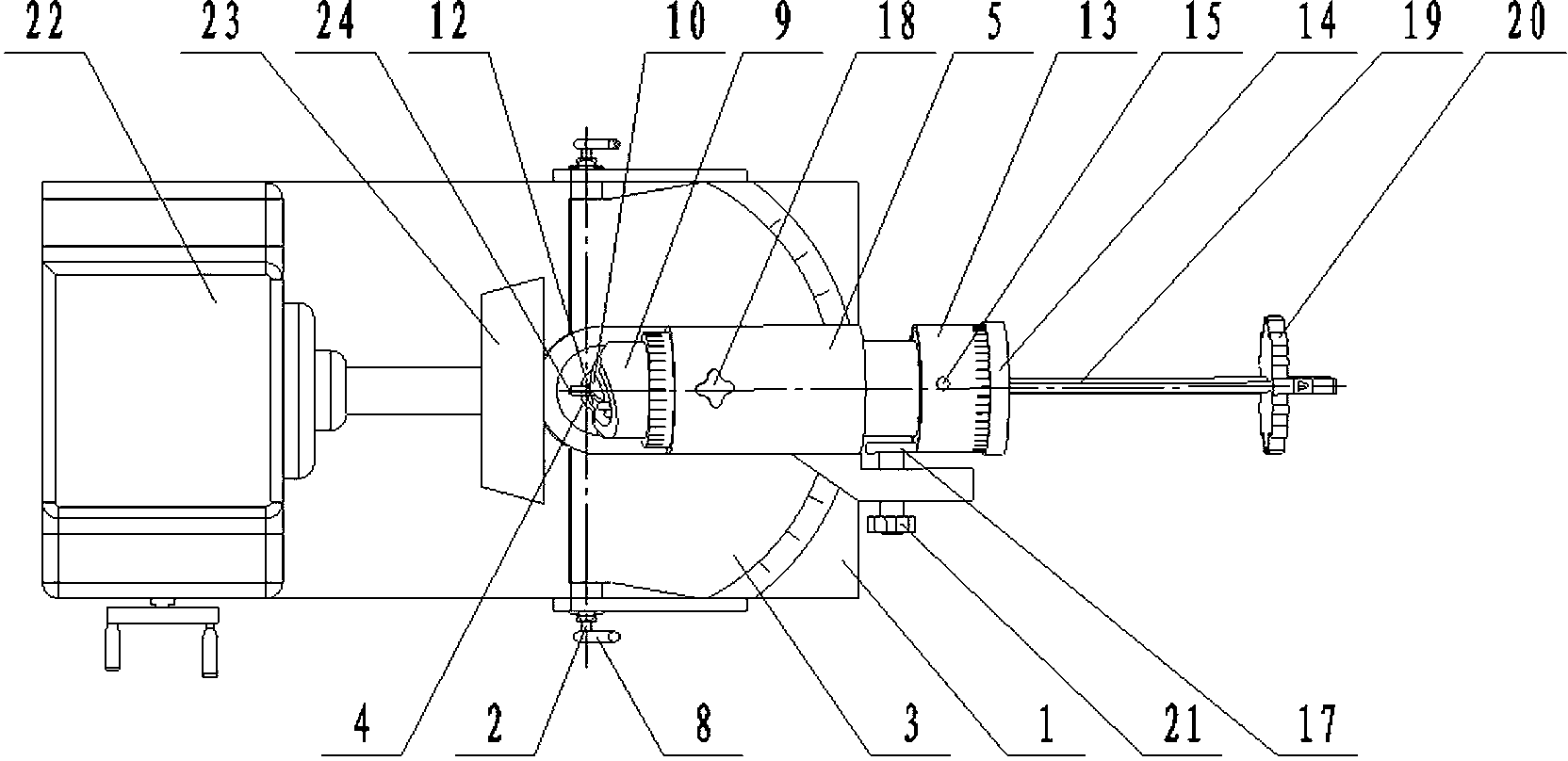

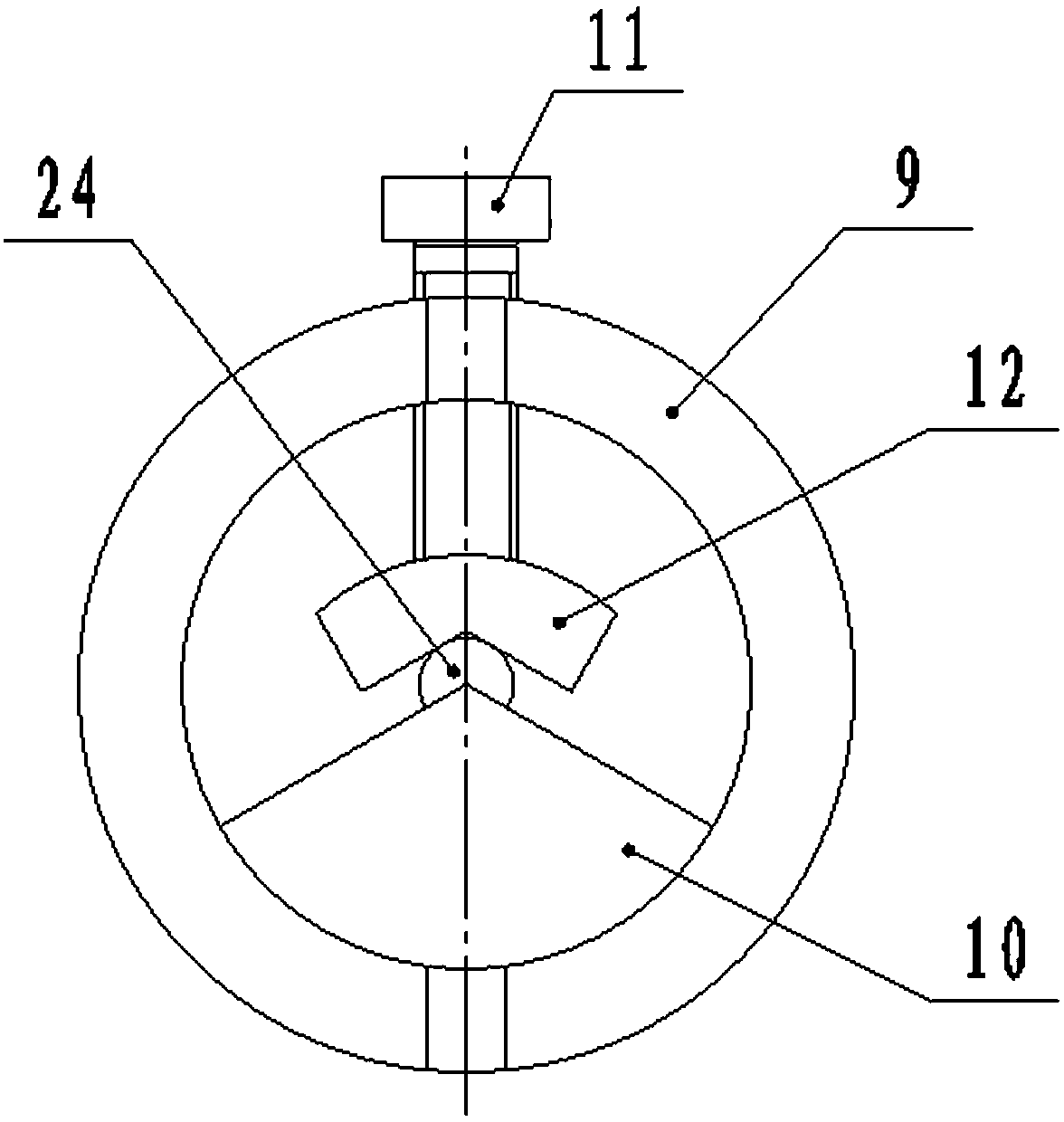

[0012] A gun drill sharpening device, comprising a base 1, an inner and outer angle dial 3, a sleeve support 5, and a rear angle dial 7; a first rotating shaft 2 is horizontally installed on the base 1; the middle part of the first rotating shaft 2 runs through horizontally The inner and outer angle dial 3, the center of the inner and outer angle dial 3 vertically runs through the second rotating shaft 4; the upper end of the second rotating shaft 4 vertically runs through the sleeve support 5; the lower end of the second rotating shaft 4 is connected with the inner and outer angle locking handle 6 The two ends of the first rotating shaft 2 vertically run through the rear angle dial 7; the edge of the rear angle dial 7 has an arc-shaped groove, and the rear angle locking shaft runs through the arc-shaped groove; the rear angle locking shaft is installed horizontally on the base 1 The two ends of the rear angle locking shaft are connected with the rear angle locking handle 8; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com