Construction method of membrane shell ribbed floor formwork supporting system

A formwork support and ribbed floor technology, which is applied in construction, building structure, and building material processing, can solve the problems of large deformation value of the formwork support system, large amount of materials, and long construction period, so as to improve the two-way lateral resistance The effect of moving stiffness and overall stability, strong operability, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

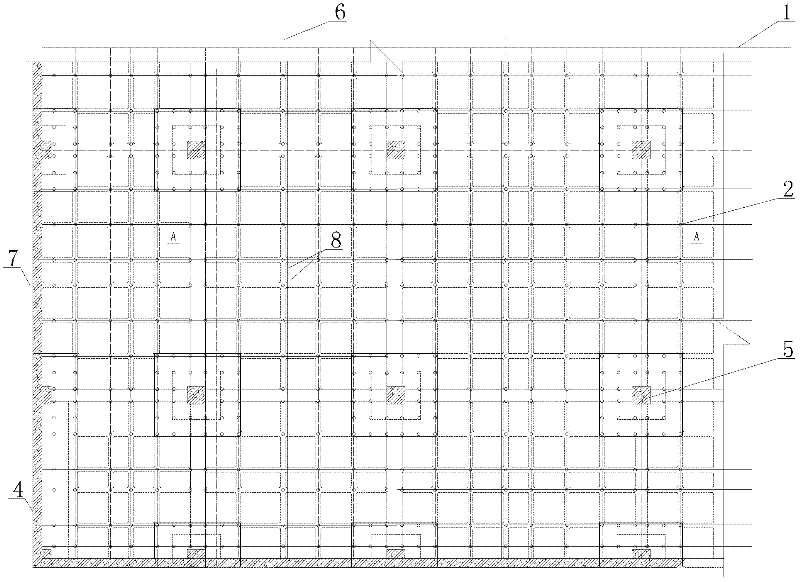

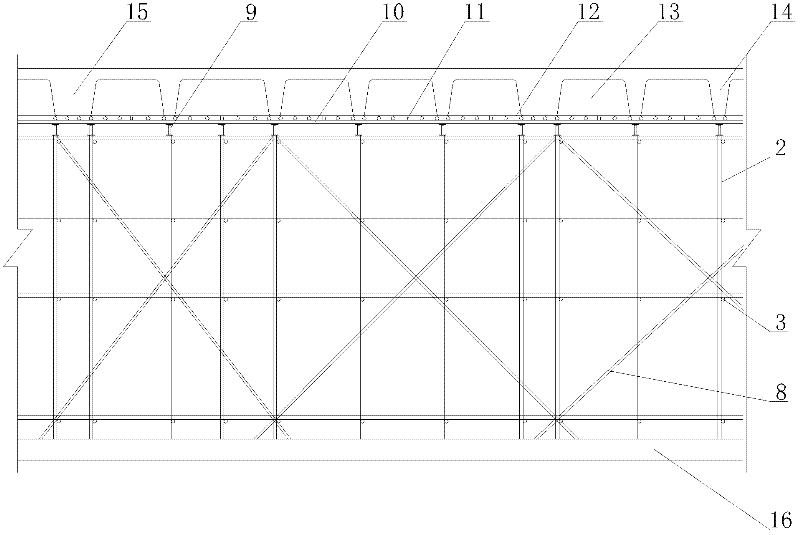

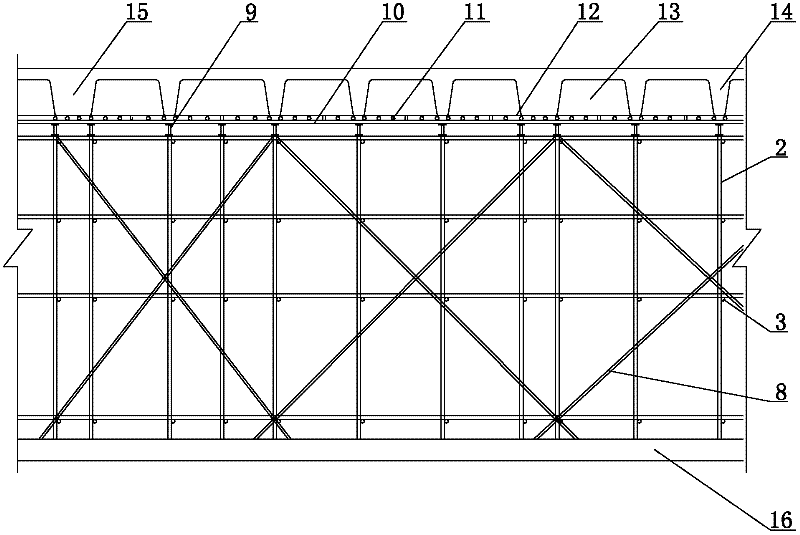

[0028] like Figure 1 ~ Figure 2 As shown, the construction method of the membrane shell ribbed formwork support system of the present invention takes the following steps:

[0029] (1) Positioning and setting out: release the vertical and horizontal center coordinate network 1 of the dense rib of the floor on the pole foundation 16;

[0030] (2) Set up poles: erect poles 2 at the cross node center of the vertical and horizontal center coordinate network 1 of the dense ribs of the floor;

[0031] (3) Set up the horizontal bar: pop up the horizontal line on the vertical bar 2 according to the 3 steps of the horizontal bar, and then set up the horizontal bar 3, and make a reliable connection between the horizontal bar 3 and the intersection of the shear wall 4 and the frame column 5;

[0032] (4) Setting up scissors braces: set up vertical continuous scissors braces 8 on the vertical centerlines 6 between each row of frame columns and the vertical centerlines 7 of the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com