Press stroke automatic adjustment structure

An automatic adjustment and press technology, which is applied in the field of presses, can solve the problems of manual adjustment, poor adjustment of eccentric sleeves and connecting rods, and difficult control of adjustment accuracy, and achieve the effect of simple stroke adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

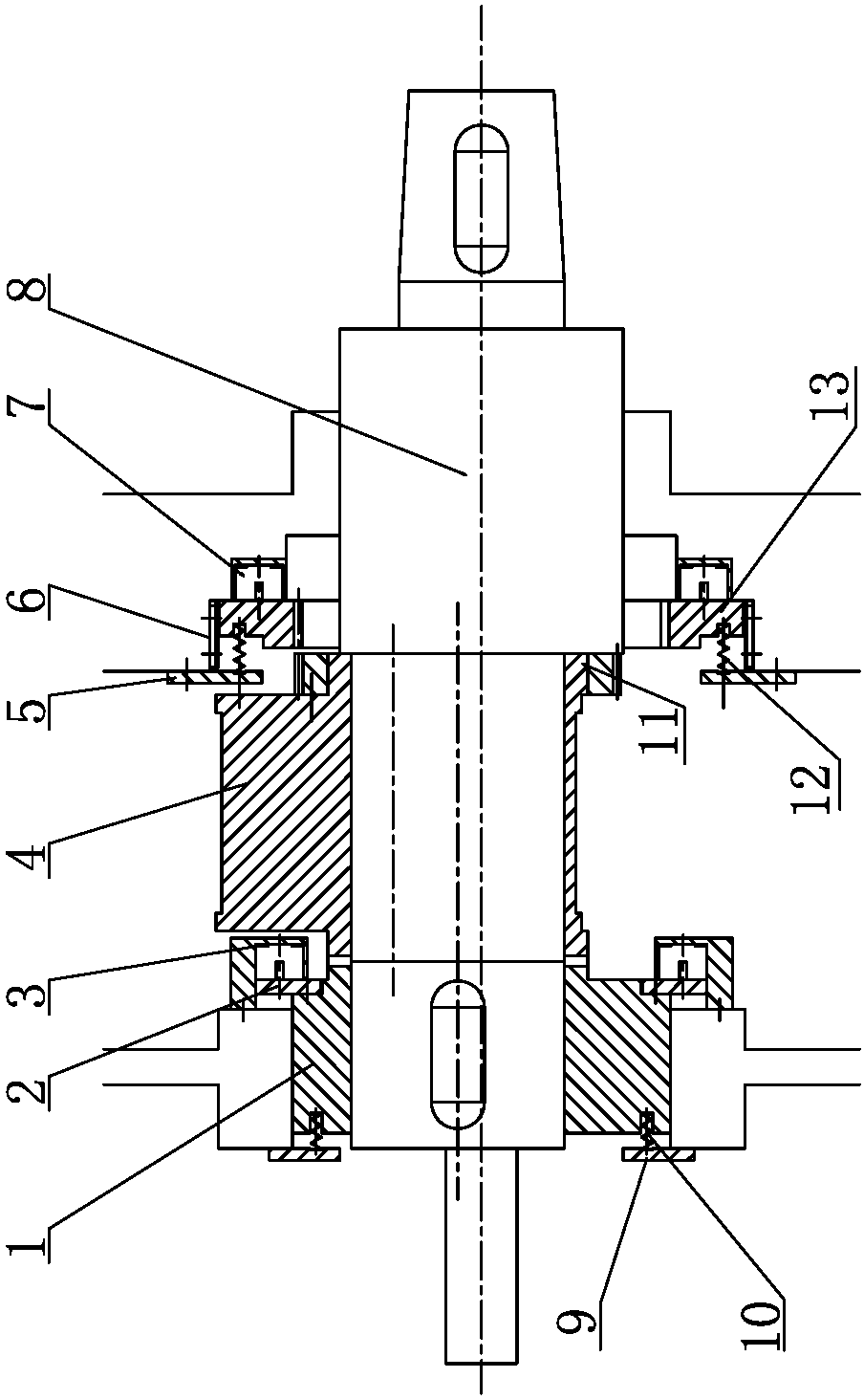

[0015] Such as figure 1 Shown is the automatic stroke adjustment structure of the press machine of the present invention, including a crankshaft 8, which is rotatably supported on the fuselage support, and an eccentric sleeve 4 that can rotate along the axial direction of the eccentric journal is sleeved on the eccentric journal of the crankshaft 8, and the eccentric One end of the sleeve 4 is provided with a locking device, and the other end is provided with an eccentricity adjustment device. The locking device includes a locking sleeve 1 which is set on the outer periphery of the eccentric journal and has the same eccentricity as the locking sleeve 1. One end of the locking sleeve 1 is provided with a spring 10, The other end is provided with a pneumatic device 1, and the corresponding end faces of the locking sleeve 1 and the eccentric sleeve 4 are respectively provided with matching locking side teeth. The eccentricity adjusting device includes an adjusting inner ring gear ...

Embodiment 2

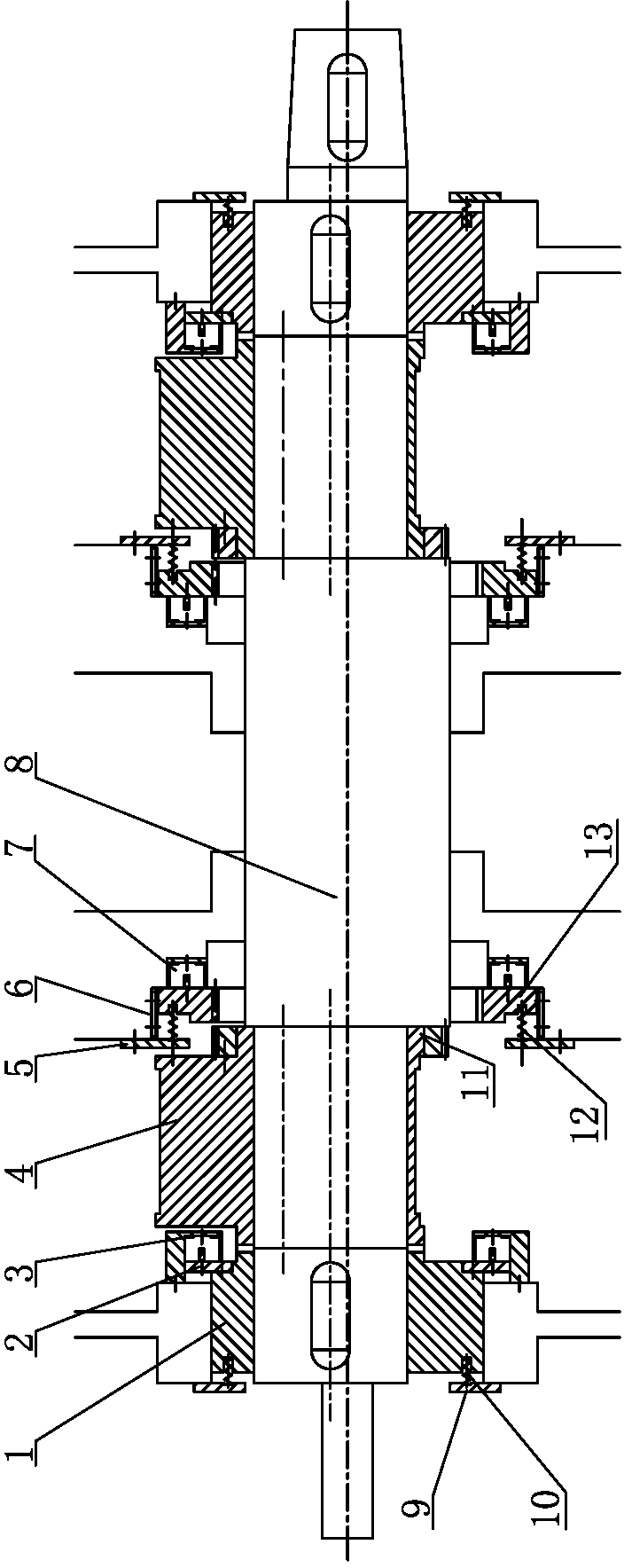

[0018] Such as figure 2 As shown, the difference from Embodiment 1 is that in this embodiment, two sets of eccentric sleeves 4 are arranged side by side on the crankshaft 8, and each set of eccentric sleeves 4 is connected to the crankshaft 8 through its own locking device and eccentric distance eccentric device. The eccentric curved neck connection realizes the synchronous adjustment of the stroke of the single-axis double-point press or the stamping movement. In the processing and manufacturing of this embodiment, the parts of the eccentric sleeve 4, the locking device and the eccentricity adjustment device are paired and processed and assembled to ensure the consistency of their assembly accuracy. During work, through the rotation of the crankshaft 8 and the synchronous action of the two sets of eccentric distance adjustment devices, the synchronous adjustment of the stroke of the two-point press is realized. The relative rotation power of the two sets of eccentric sleeves...

Embodiment 3

[0020]The difference from Embodiment 1 is that in this embodiment, the crankshafts 8 are two groups arranged side by side and rotate synchronously through mutually meshing gears. Each group of crankshafts 8 is provided with eccentric sleeves 4 respectively, and each group of eccentric sleeves 4 passes through the The locking device and the eccentric distance adjusting device are connected with the eccentric journal of the crankshaft 8 to realize the synchronous adjustment or stamping movement of the stroke of the biaxial double point press. In this embodiment, the actions of the two sets of eccentric sleeves 4 are realized by the synchronous rotation of the two sets of crankshafts 8. The gears with the same parameters and paired with each other can ensure the synchronous rotation of the two sets of crankshafts 8 and drive the two sets of eccentric The synchronous action of sets 4 realizes the synchronous adjustment of the stroke of the biaxial double point press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com