Electric weeding machine

A weeding machine, electric technology, applied in the direction of weeding tools, weed eradication equipment, agricultural machinery and implements, etc., can solve the problems of human body prone to fatigue, easy to shake, affect the operating comfort, etc., to improve the operation The effect of comfort, efficiency improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

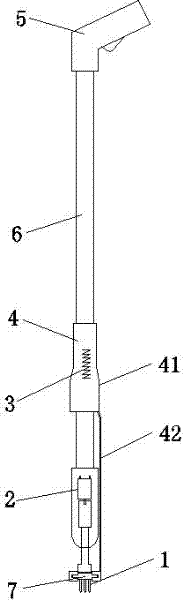

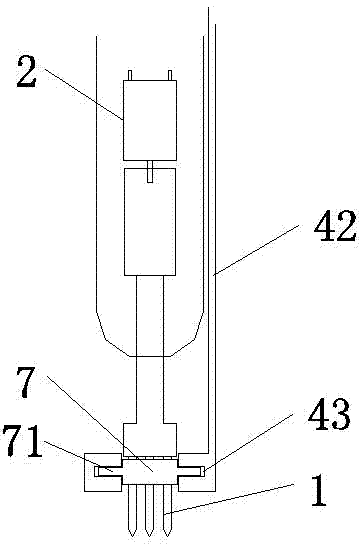

[0024] Such as figure 1 Shown, electric weeder of the present invention mainly comprises power unit, and power unit adopts motor 2, and the working head 1 that drives axial rotation, connecting rod 6 and the main handle 5 that is located at connecting rod 6 other ends by power device. One end of the connecting rod 6 fixes the motor 2 . Connecting rod 6 is a longer pole, and is suitable for operating the weeder when the operator stands. In other embodiments, the connecting rod 6 can also be made as a telescopic rod, which can adjust the working length of the machine to suit different operators to operate the machine.

[0025] The motor 2 is arranged at one end of the connecting rod 6 near the working head 1, and the main handle 5 at the other end of the connecting rod 6 is provided with a switch for controlling the opening and closing of the motor 2.

[0026] A push-off handle 4 movable in the axial direction is arranged on the connecting rod 6 , and the push-off handle 4 is ...

Embodiment 2

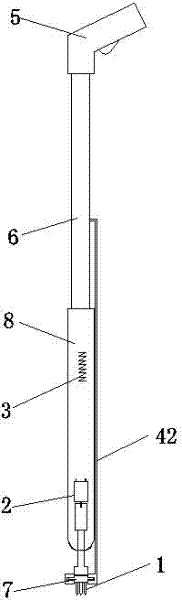

[0032] Such as image 3 , Figure 4 As shown, the electric weeder in this embodiment mainly includes a motor 2, a working head 1 driven by the motor 2 to drive the transmission device to rotate axially, a main body shell 8 to fix the motor 2 at one end thereof, and the other end of the main shell 8 It is relatively slidably socketed with one end of the connecting rod 6, and the main body shell is equivalent to the push handle in Embodiment 1 and has been lengthened. The other end of the connecting rod 6 is provided with a main handle 5 . Connecting rod 6 is a longer pole, and is suitable for operating the weeder when the operator stands. In other embodiments, the connecting rod 6 can also be made as a telescopic rod, which can adjust the working length of the machine to suit different operators to operate the machine.

[0033] The push-off baffle 7 is provided with a hole that can accommodate the working head 1 to pass through, so that the push-off baffle 7 can slide on the...

Embodiment 3

[0041] In the operation mode of pushing the grass in Embodiment 1 and Embodiment 2, in addition to the operation by hand, it can also be operated by feet, and the operation of pushing the grass by setting a pedal suitable for the foot can avoid the need to push the grass by hand. It is often necessary to bend over to make pushing the grass more convenient and labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com