Printing device and control method therefor

一种打印装置、控制方法的技术,应用在打印装置、印刷等方向,能够解决条形码读取不良、打印品质下降、打印条形码等问题,达到抑制读取品质的下降、维持打印品质、消除输送误差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] printing device

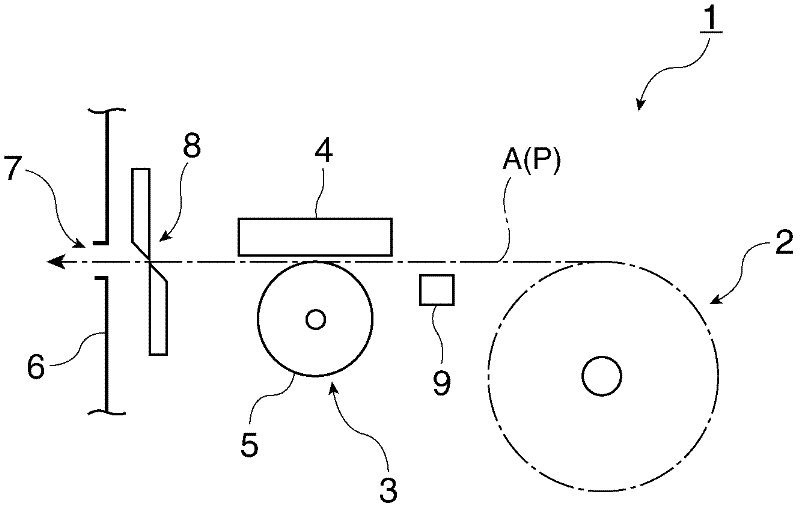

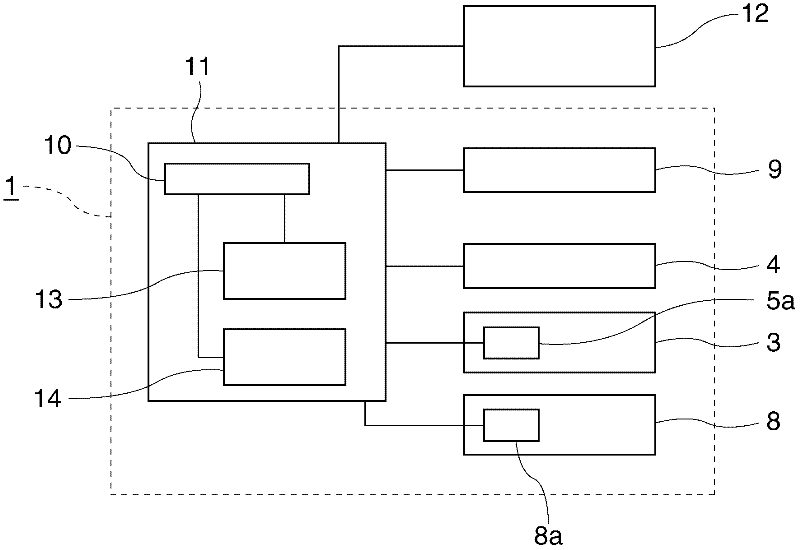

[0050] Embodiments to which the present invention is applied will be described below with reference to the drawings. figure 1 It is an explanatory diagram showing a schematic configuration of a main part of the thermal printer according to the embodiment of the present invention. The thermal printer 1 (printing device) is equipped with: a roll paper storage unit 2 for storing the roll paper that rolls the long recording paper P into a roll shape; The recording paper P ejected from the roll paper in the roll paper accommodating portion 2; and the thermal printhead 4 (print head) disposed at the printing position B on the conveying path A facing the heat generating portion are conveyed.

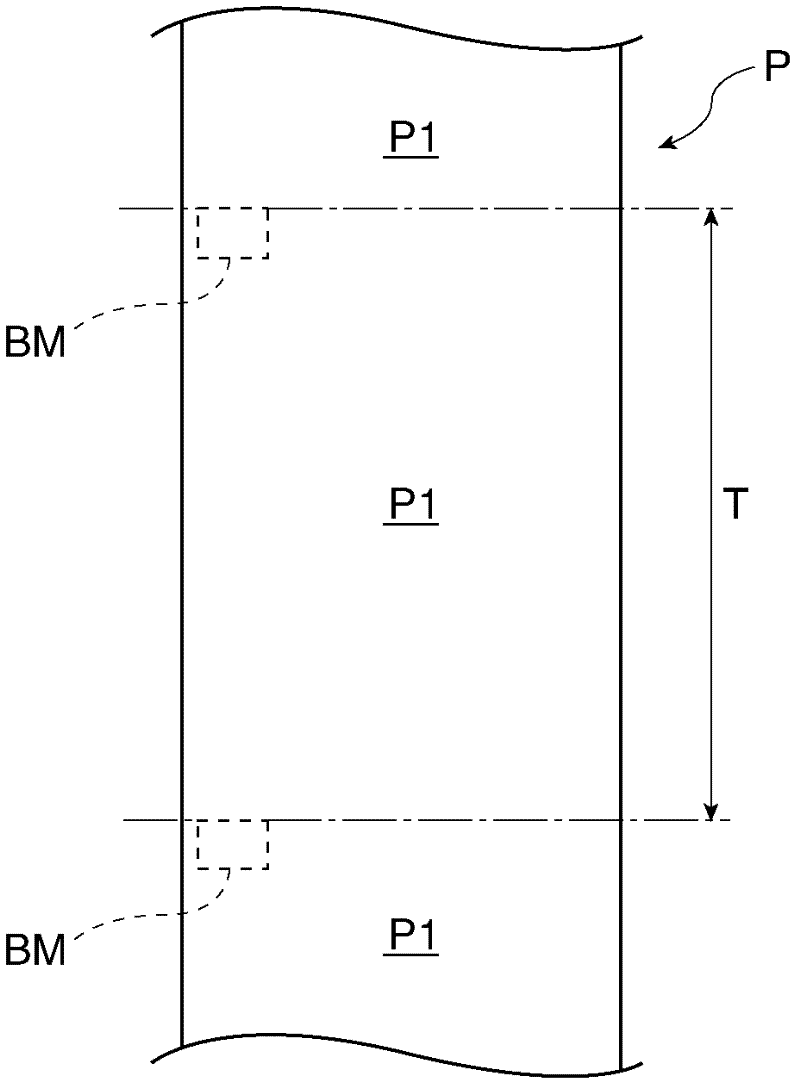

[0051] figure 2It is a plan view of the recording paper P. In this embodiment, long continuous paper is used as the recording paper P, and the surface of the recording paper P is provided with a thermosensitive color-developing layer. On the back of the recording p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com