Water circulating foam washing device and its washing method

A laundry device and water flow technology, which is applied to washing devices, washing machines with containers, textiles and papermaking, etc., can solve the problems of unsatisfactory and unsatisfactory dry cleaning effects, and achieve the effects of caring for clothes, ingenious design, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

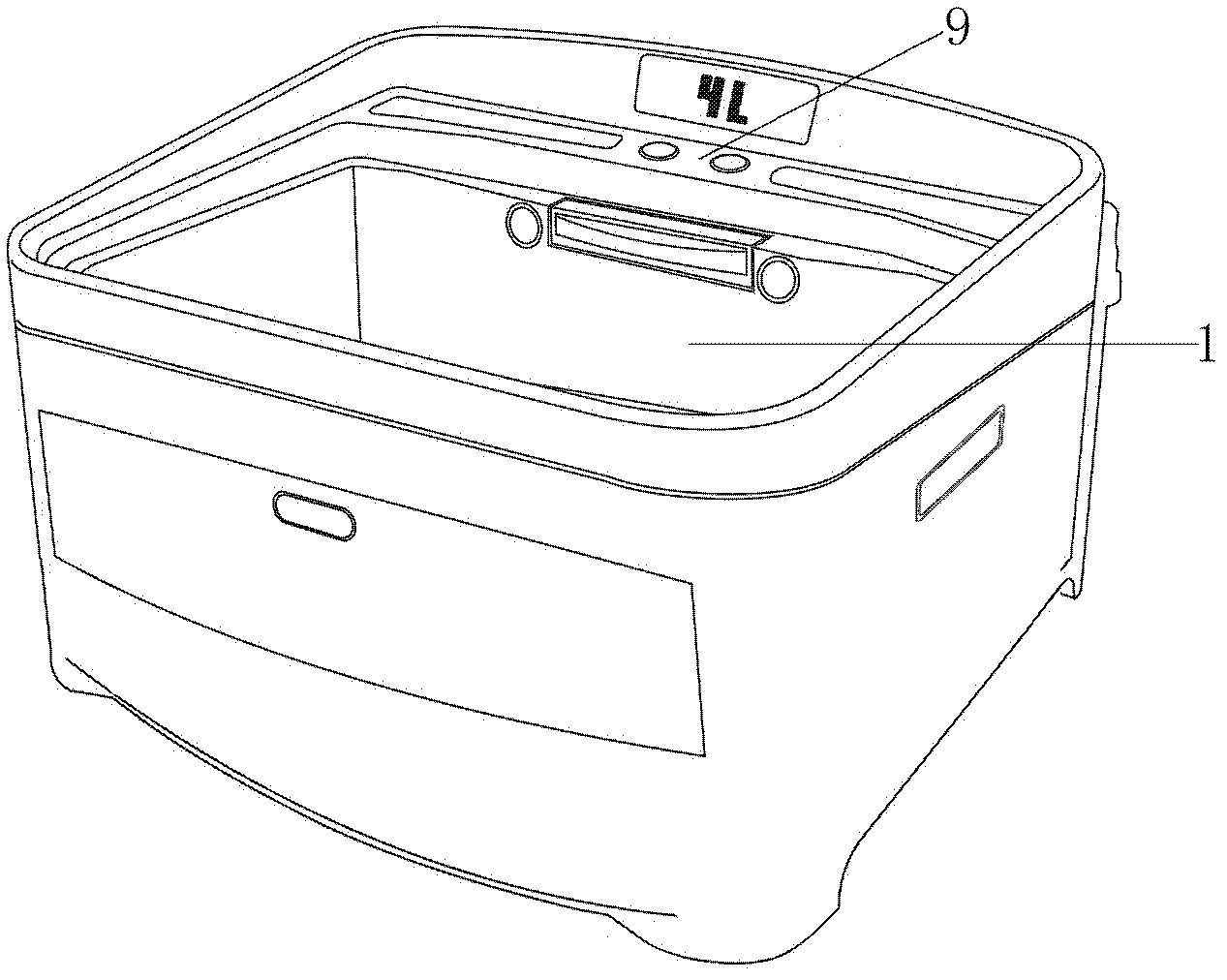

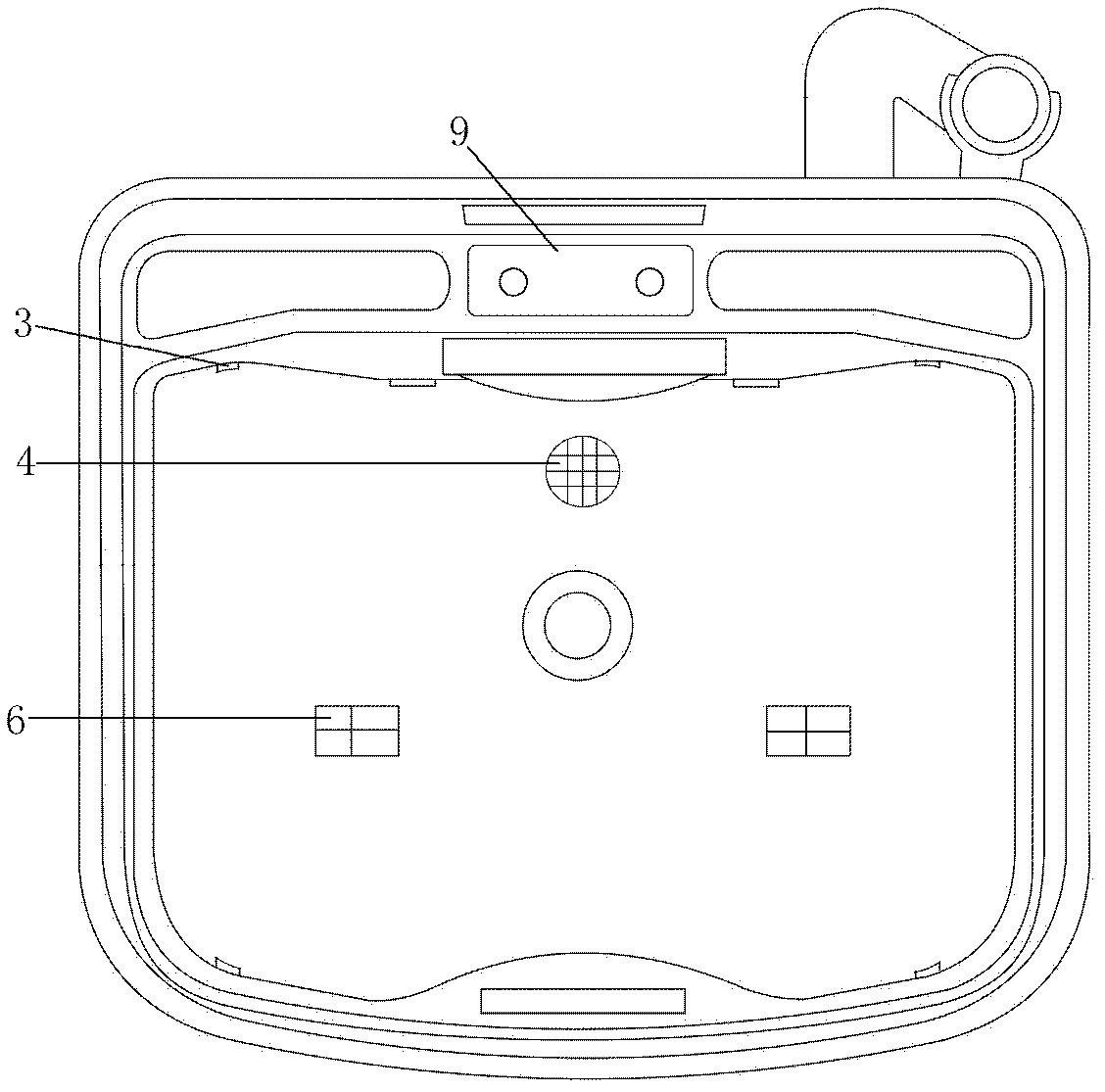

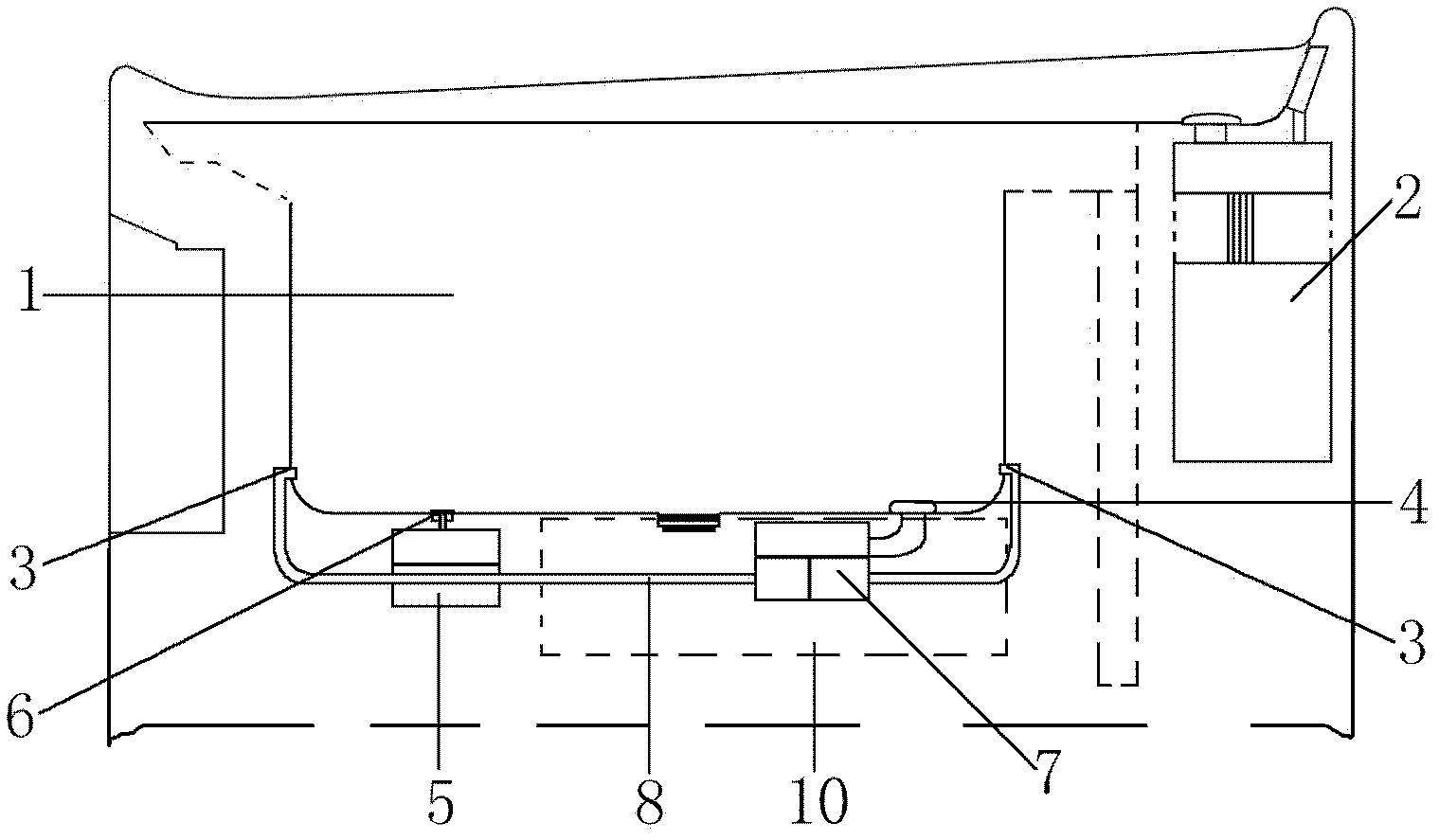

[0027] A water circulation foam laundry device, comprising a washing container (1) and a program control device (2), characterized in that a circulating power device (10) and a foam generator (5) are arranged on the base of the washing container (1); The bottom of the container (1) is provided with a washing water outlet (4), an aeration device (6), and a washing water inlet (3) is provided on the side wall; The water outlet (4) and the washing water inlet (3) are connected, and the foam generator (5) is connected to the pipeline of the aeration device (6); the program control device (2) is arranged on the shell of the washing container (1), and the program The control device (1) is electrically connected with the cycle power device (10) and the foam generator (5).

[0028] The circulating power unit (10) is composed of a circulation pump (7) and a conduit (8), and the circulation pump (7) is connected to the washing water outlet (4) and the washing water inlet (3) respectivel...

Embodiment 2

[0038] A water circulation foam washing laundry device, such as Figure 5 , Image 6 As shown, the structure and method are the same as in Example 1, the difference is that the circulating power device is composed of a circulating pump, a conduit, and a water spinning device, and the circulating pump is respectively connected to the washing water outlet and the washing water inlet through the conduit , the water spinning device includes a water flow changing device, a water spinning wheel and a motor, the water spinning wheel is arranged at the bottom of the washing container, the water flow changing device is installed above the water spinning wheel, the motor is connected with the water spinning wheel through a power shaft, the circulation pump, the motor and the program Control unit circuit connections.

[0039] The internal rotating water flow refers to the changing water flow formed by the washing water passing through the water rotating device.

Embodiment 3

[0041] A water circulation foam washing laundry device, such as Figure 5 , Image 6 As shown, the structure and method are the same as those in Embodiment 2. The difference is that the internal rotating water flow refers to the changing water flow formed by changing the input of the washing water inlet and the water rotating device when the circulating power device is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com