Twist compression type washing machine

A technology of washing machine and inner barrel cover, applied in the field of washing machine, which can solve the problems of heavy load on the upper cover, high center of gravity of the body, difficulty in improving decontamination efficiency, etc., and achieve the effect of reduced water consumption, reduced power consumption, and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the invention is further described.

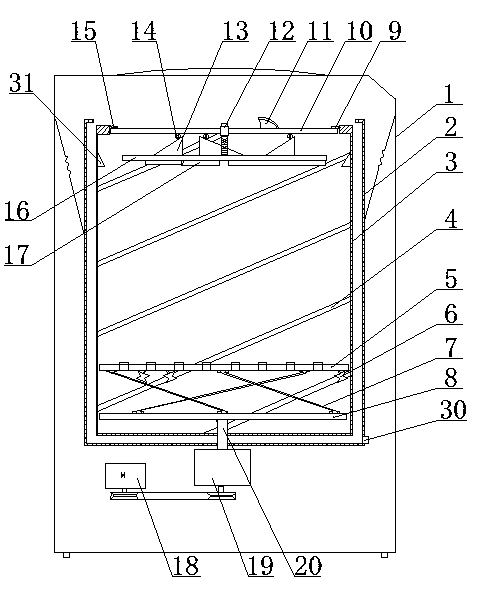

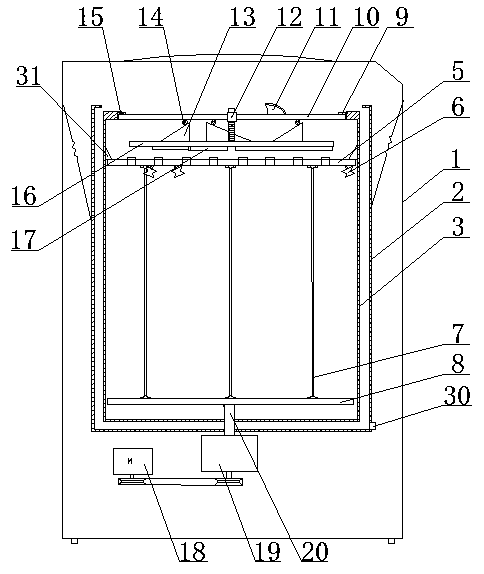

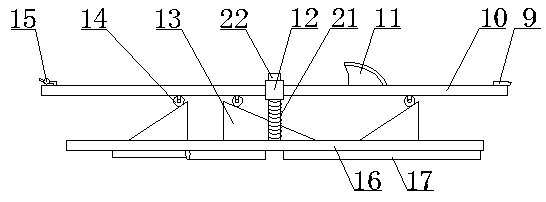

[0030] Depend on figure 1 , 2 It can be seen that the torsional pressure washing machine includes a casing 1, an outer tub 2, an inner tub 3 and an inner tub cover 10, the casing is provided with a water inlet and a controller, the power mechanism is electrically connected with the controller, the outer tub is provided with a water outlet 30, and the inner wall of the inner tub is Drainage holes and three equidistant spiral guide rails 4 are arranged on the top, and a stop block 31 is set on the inner wall of the inner barrel corresponding to the height of the driven plate to help the piston plate return when the washing machine is idling; the inner barrel cover is provided with a spiral sleeve 12, Slope track groove 29, driven disk 16, screw shaft 22, buffer spring 21 and slope track 13 form the pressure mechanism, the center of the inner barrel cover is provided with a spiral sleeve and a slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com