Combined type plug and socket structure

A plug and socket, combined technology, applied in the direction of coupling devices, electrical components, circuits, etc., can solve the problems of limited jacks, single function, and occupying a lot of space, so as to avoid interference and ensure the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

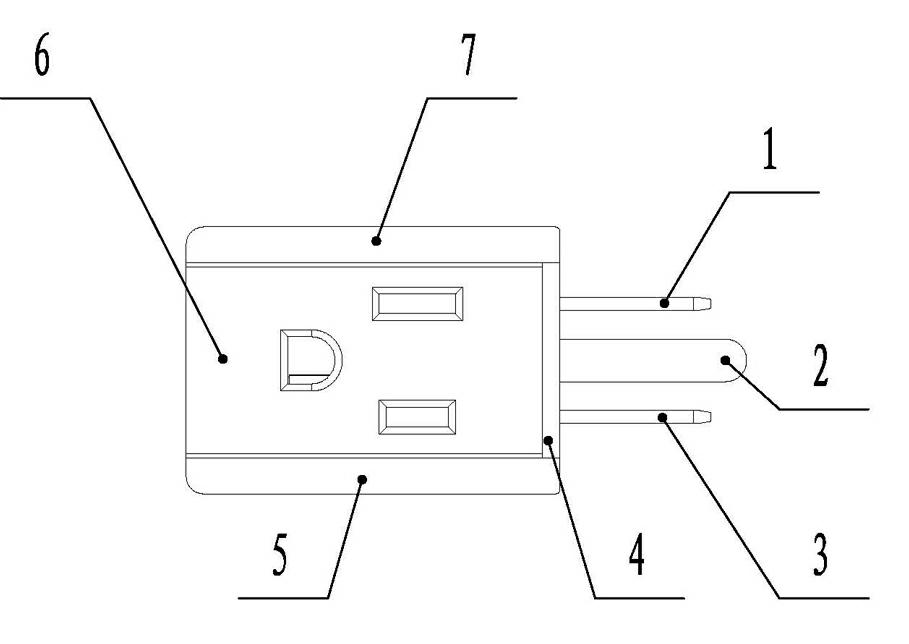

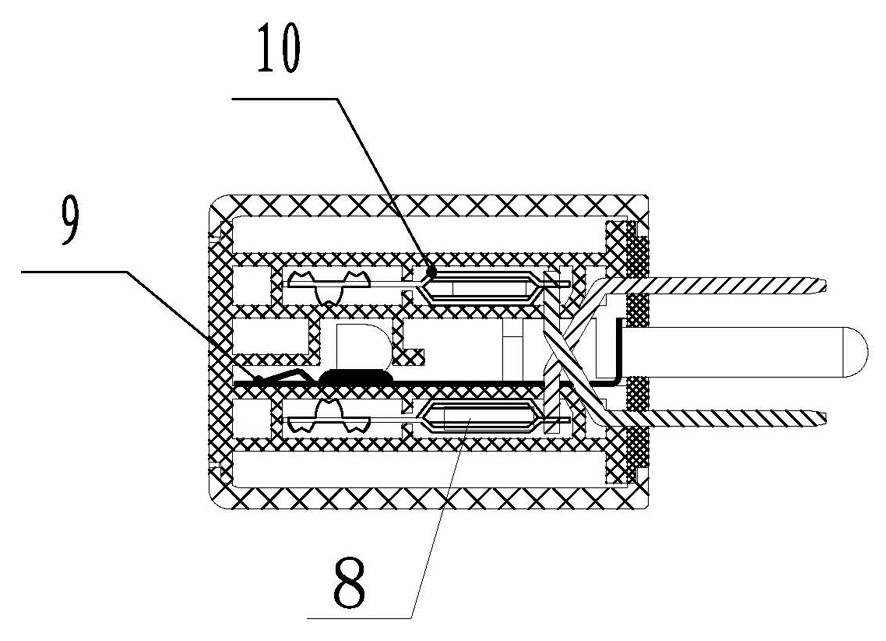

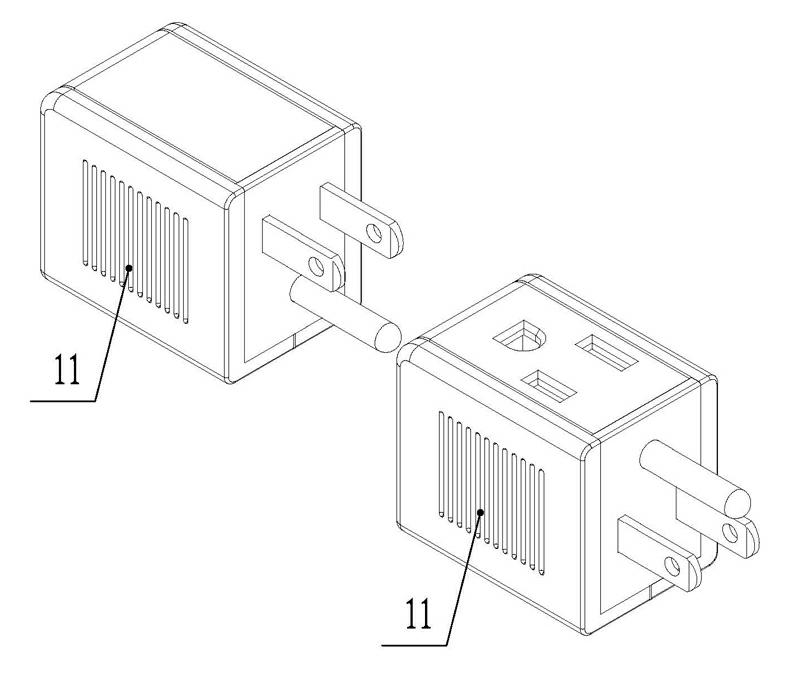

[0014] As shown in the figure, this combined plug and socket structure mainly includes a socket unit. The socket unit includes a body 6. The three sides of the body 6 are respectively provided with a left end cover 5, a bottom cover 4 and a right end cover 7. The left end cover 5 and the right end The cover 7 is provided with concave-convex stripes 11, which are convenient to grasp without slipping. One side of the bottom cover 4 is provided with a live wire pin 1, a grounding pin 2 and a neutral wire pin 3. The upper part of the body 6 and the opposite side of the bottom cover 4 are both There is a jack for plugging in another socket unit. The inside of the body 6 is provided with a live wire socket 8, a grounding socket 9 and a neutral wire socket 10. The live wire socket 8 is connected to the live wire pin 1, and the grounding socket 9 is connected to the grounding socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com