Die and method for manufacturing die, and anti-reflection coating

A manufacturing method and technology of anti-reflection film, which can be applied to household appliances, other household appliances, surface reaction electrolytic coatings, etc., can solve the problems of reduced visual recognition, reduced light transmission, etc., and achieve the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Next, a moth-eye mold according to an embodiment of the present invention and a method of manufacturing the same will be described with reference to the drawings.

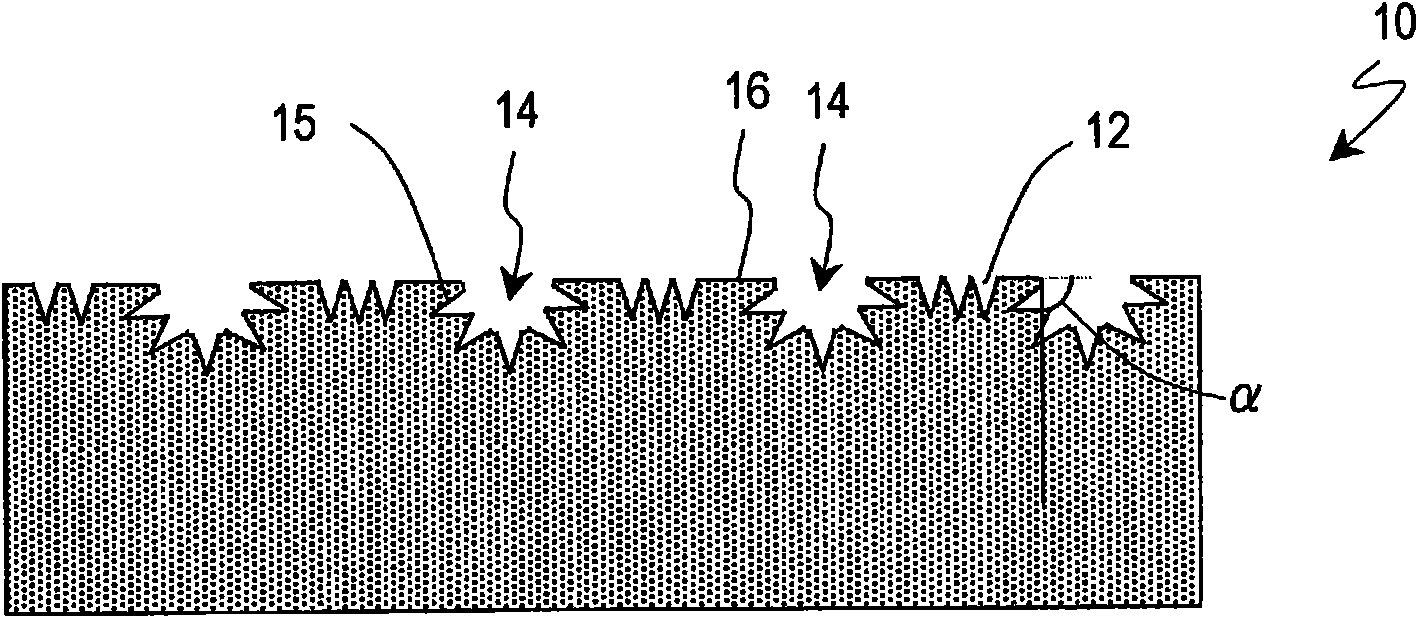

[0053] figure 1 It is a schematic cross-sectional view of the moth-eye mold 10 according to the embodiment of the present invention. Such as figure 1 As shown, the moth-eye mold 10 has an anodized porous alumina layer on the surface, and has a plurality of first recesses 12 and a plurality of second recesses 14 . The plurality of second recesses 14 has a two-dimensional size of 190 nm or more and less than or equal to 50 μm when viewed from the normal direction of the surface, and has a shape in which a plurality of fine recesses 15 with a two-dimensional size of 10 nm or more and 200 nm or less are formed on the inner surface. The plurality of first recesses 12 have a two-dimensional size of not less than 10 nm and not more than 200 nm, and are formed between the plurality of second recesses 14 . The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com