Single-cable electric grab bucket

A technology of electric grab and single rope, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of large occupied space, heavy grab bucket, and poor grasping of goods by the grab bucket, so as to reduce the occupied space Space, improved handling capacity, strong handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is described in further detail.

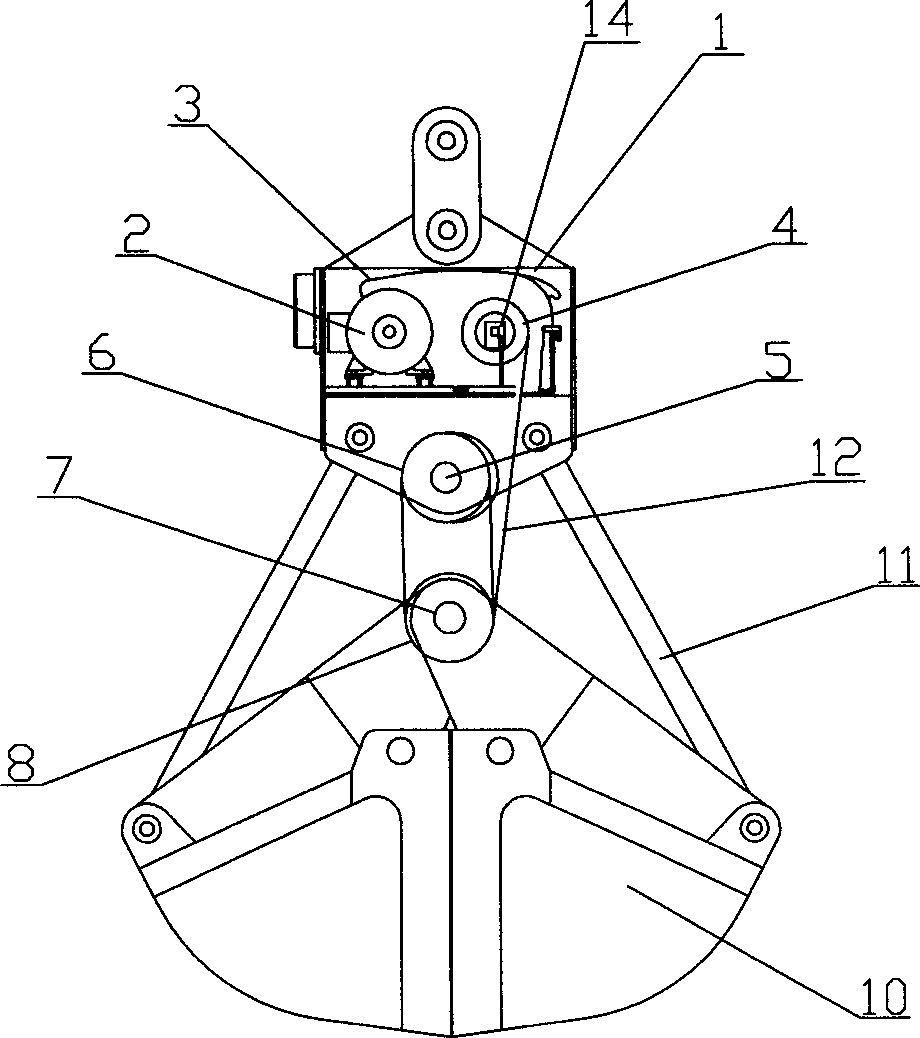

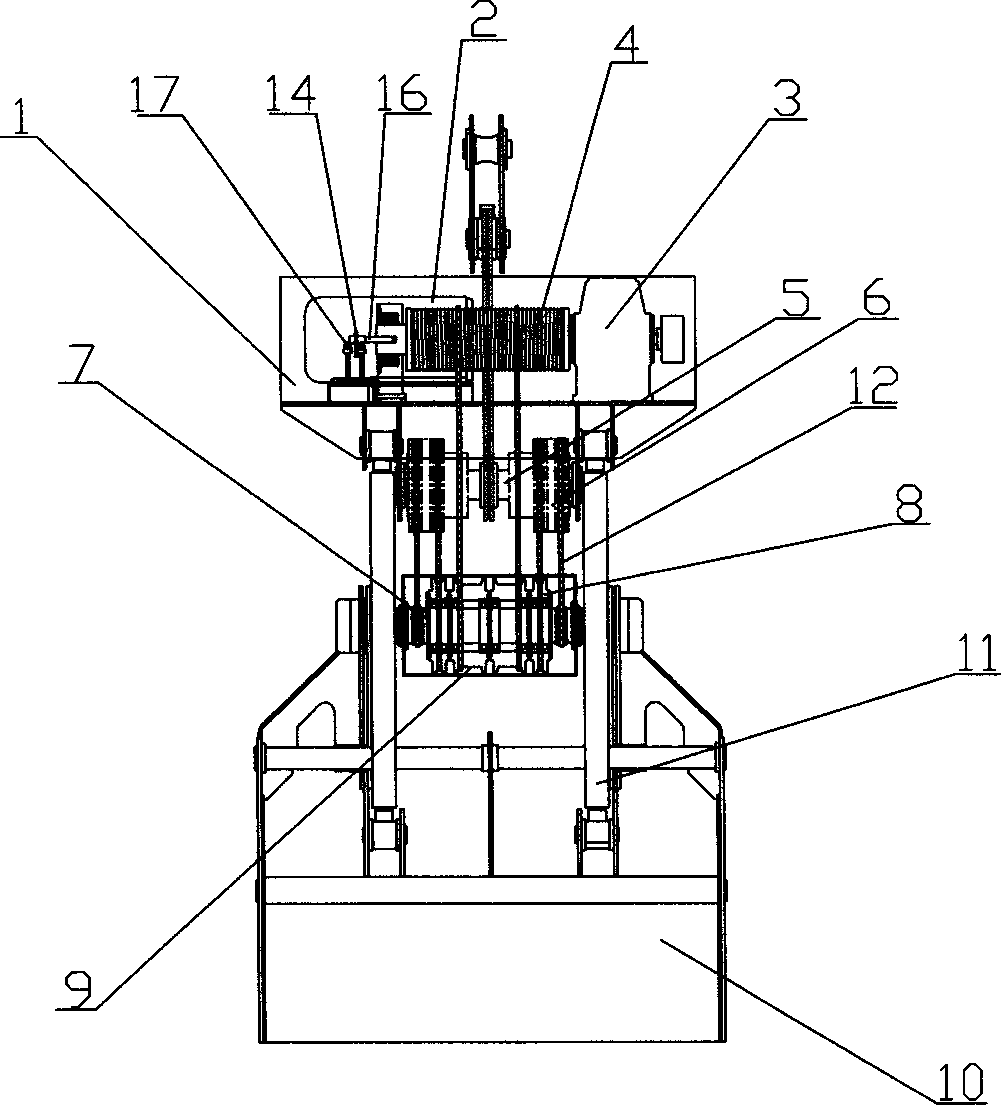

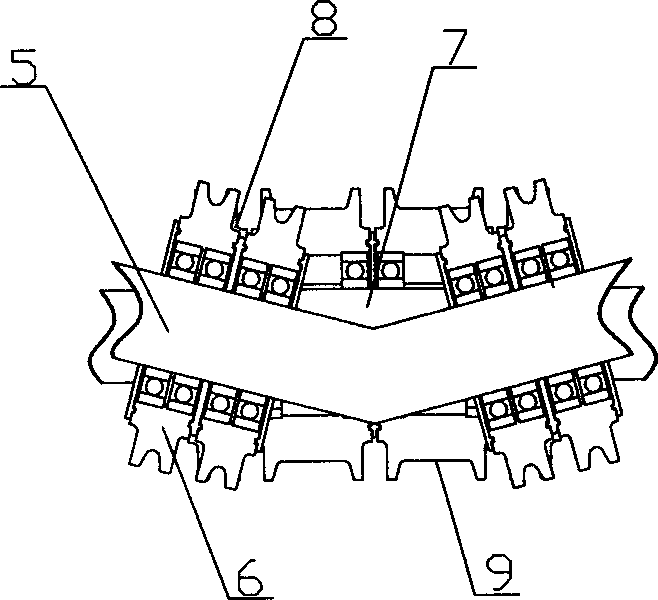

[0014] Depend on figure 1 , figure 2 with image 3 It can be seen that a single-cable electric grab according to the present invention includes a head cover 1, a motor 2, a reducer 3, a steel wire roller 4, an upper bolster, an upper bolster pulley, a lower bolster, a lower bolster pulley, Two bucket bodies 10, support rods 11, steel wire ropes 12 and grab opening and closing control devices; the motor 2, the reducer 3 and the steel wire roller 4 are arranged inside the hood 1, and the upper bolster 5 is arranged under the hood 1 , the upper bolster 5 is arranged in a figure-eight shape on the horizontal plane, and the upper bolster 5 is actually a folded whole shaft on the horizontal plane. Bearing beam pulley 6, lower bearing beam 7 is provided at the lower corresponding position of upper bearing beam 5, lower bearing beam 7 is a straight shaft, and lower bearing beam 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com