Hot-water boiler for a hot-water mat

A hot water pad and water heater technology, applied in water heaters, fluid heaters, hot water central heating systems, etc., can solve problems such as inconvenience of hot water overflow, scalding and lowering of water heaters, and avoid water shortage or scalding accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Refer below Figure 1 to Figure 9 The present invention will be described in detail.

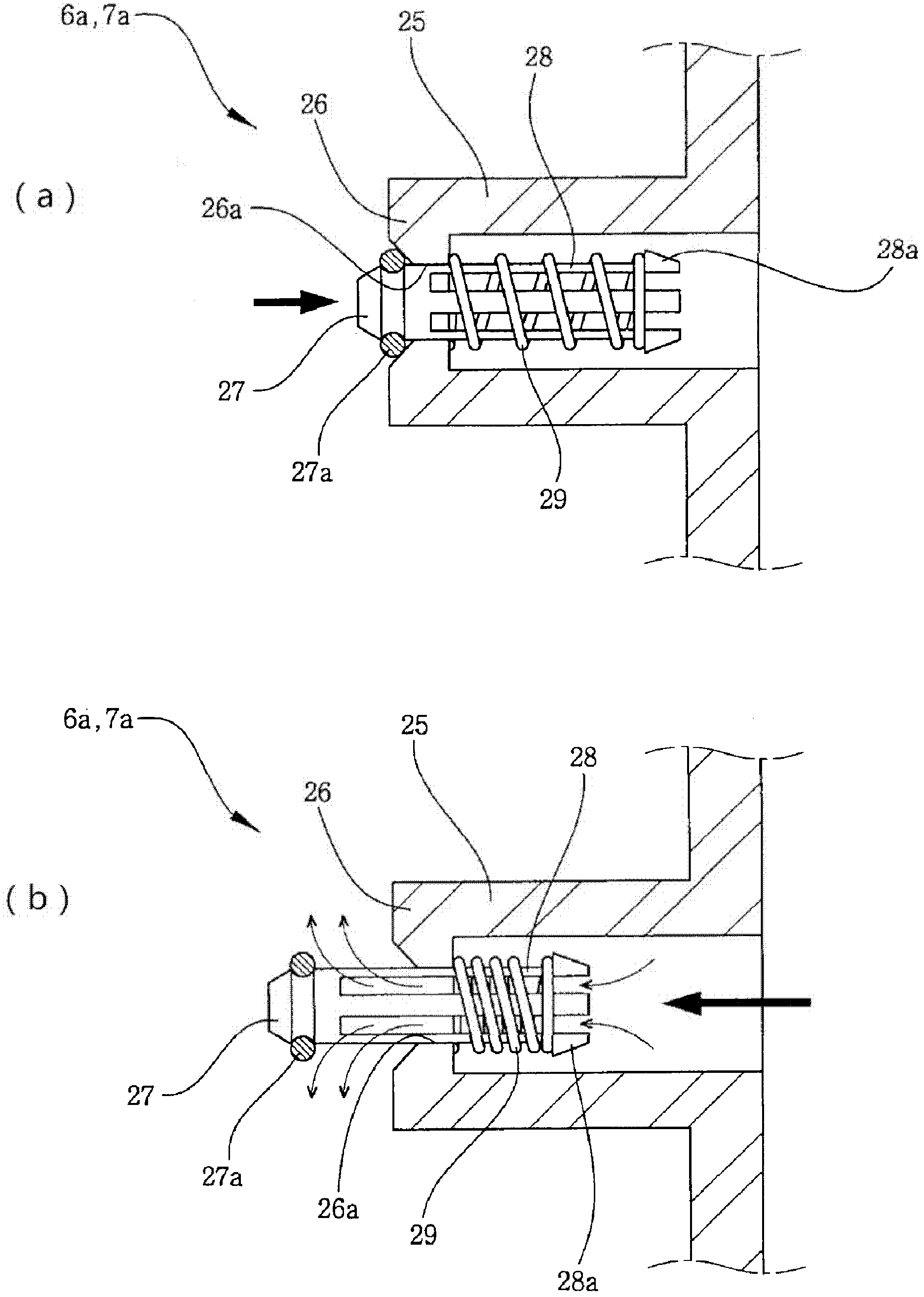

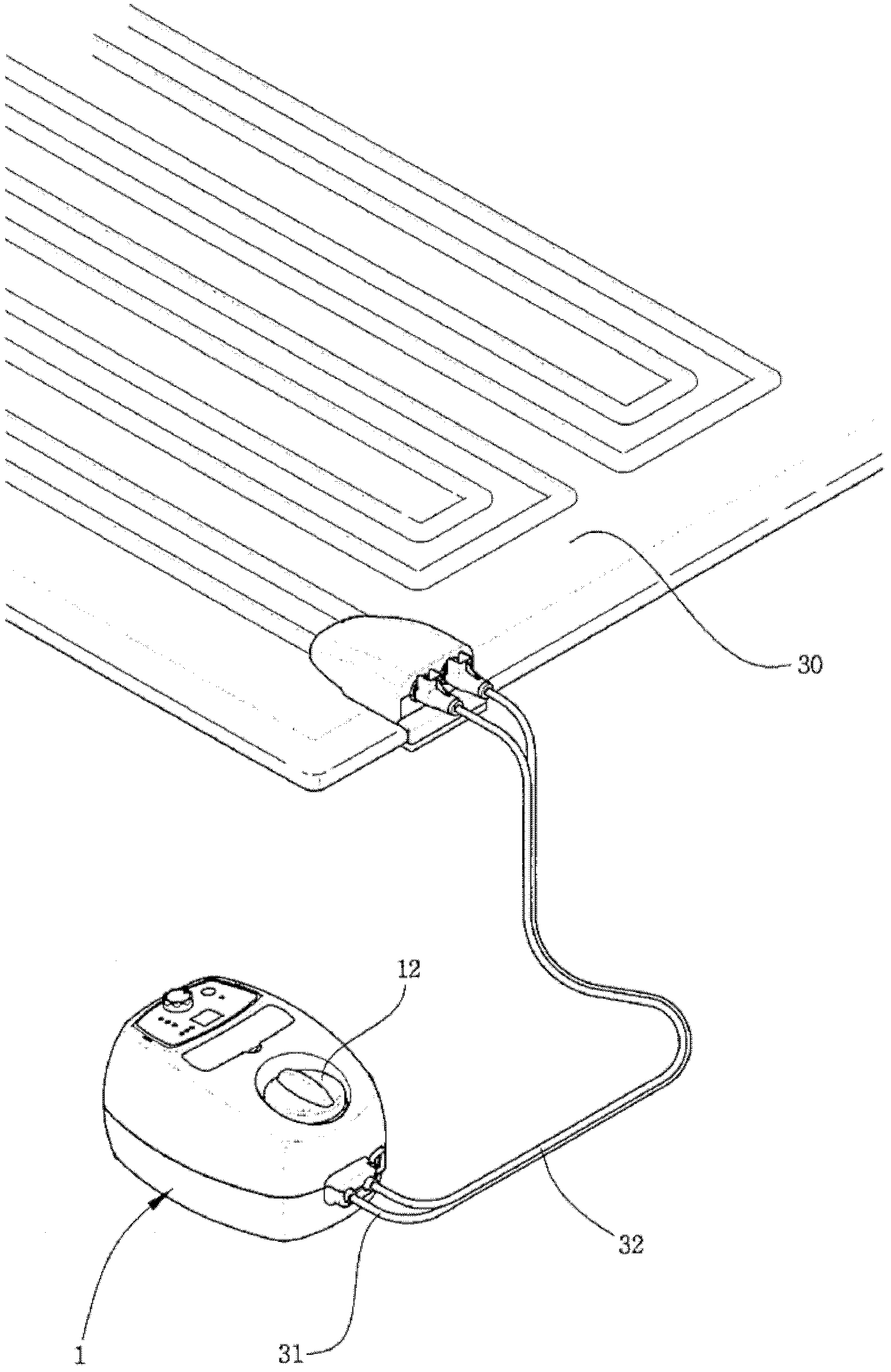

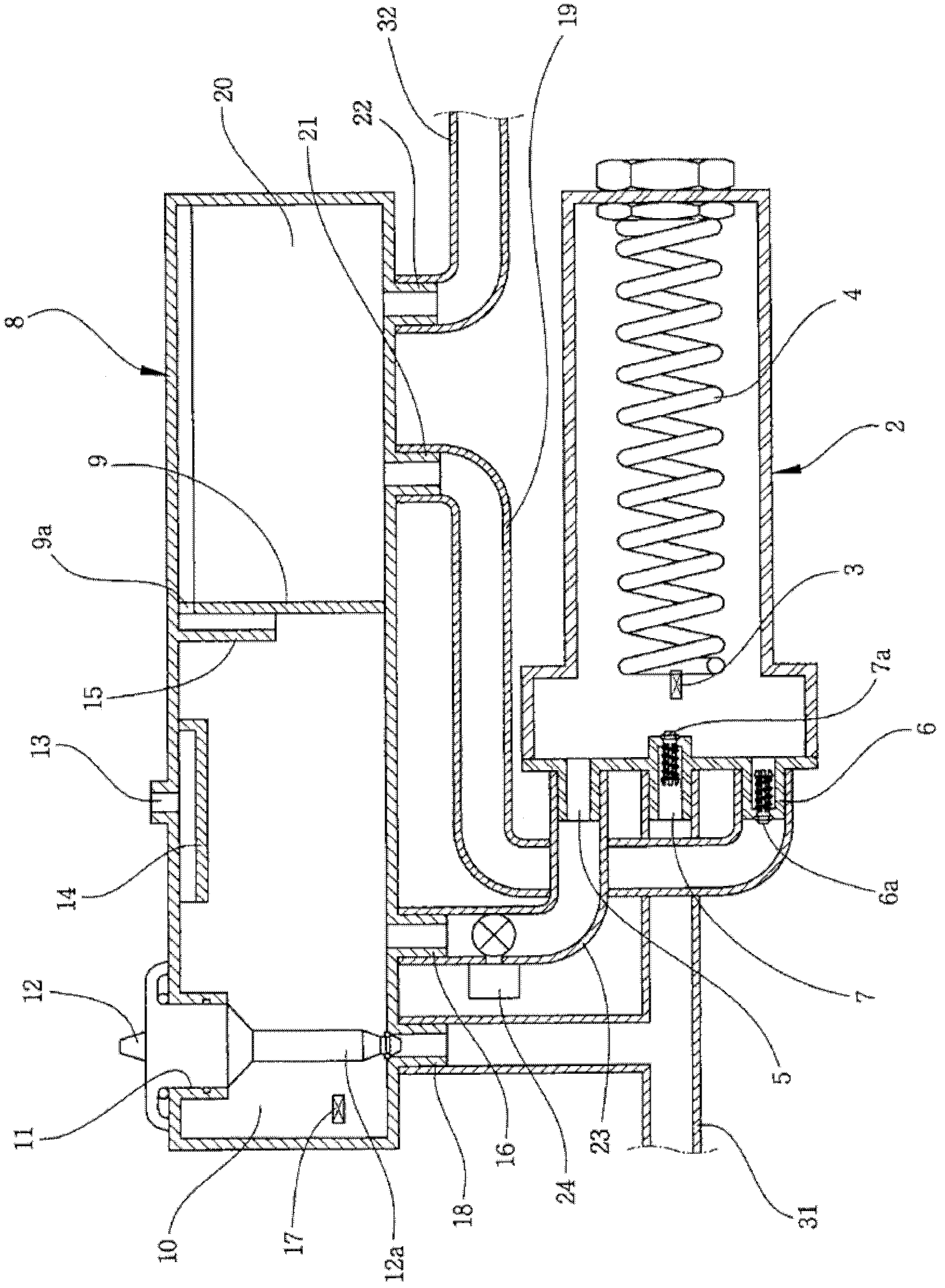

[0024] Such as figure 1 and figure 2 As shown, the water heater for a hot water pad of the present invention is specifically described as a water heater 1 for a hot water pad that heats hot water through an electric heater 4 and circulates the hot water inside the hot water pad 30 so as to supply heat to the hot water pad 30, wherein A hot water heating barrel 2 is arranged under the inner side of the water heater 1, a water level sensor 3 and an electric heater 4 are arranged inside the hot water heating barrel 2, and a backfill water inflow port 5 is formed on one side of the outside, and a backfill water inflow port 5 is formed on the other side of the outside. The hot water outflow end 6 and the hot water recovery end 7 of the check valves 6a, 7a are respectively provided.

[0025]The water level sensor 3 installed inside the hot water heating barrel 2 can detect the water lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com