Line-type temperature-sensing self-starting extra-high-pressure fire extinguishing agent release device

A technology of releasing device and fire extinguishing agent, applied in fire rescue and other directions, can solve the problems of insufficiency, low strength of temperature-sensing glass ball, limited application range of fire extinguishing device, etc., and achieve the effect of large protection range and high storage pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

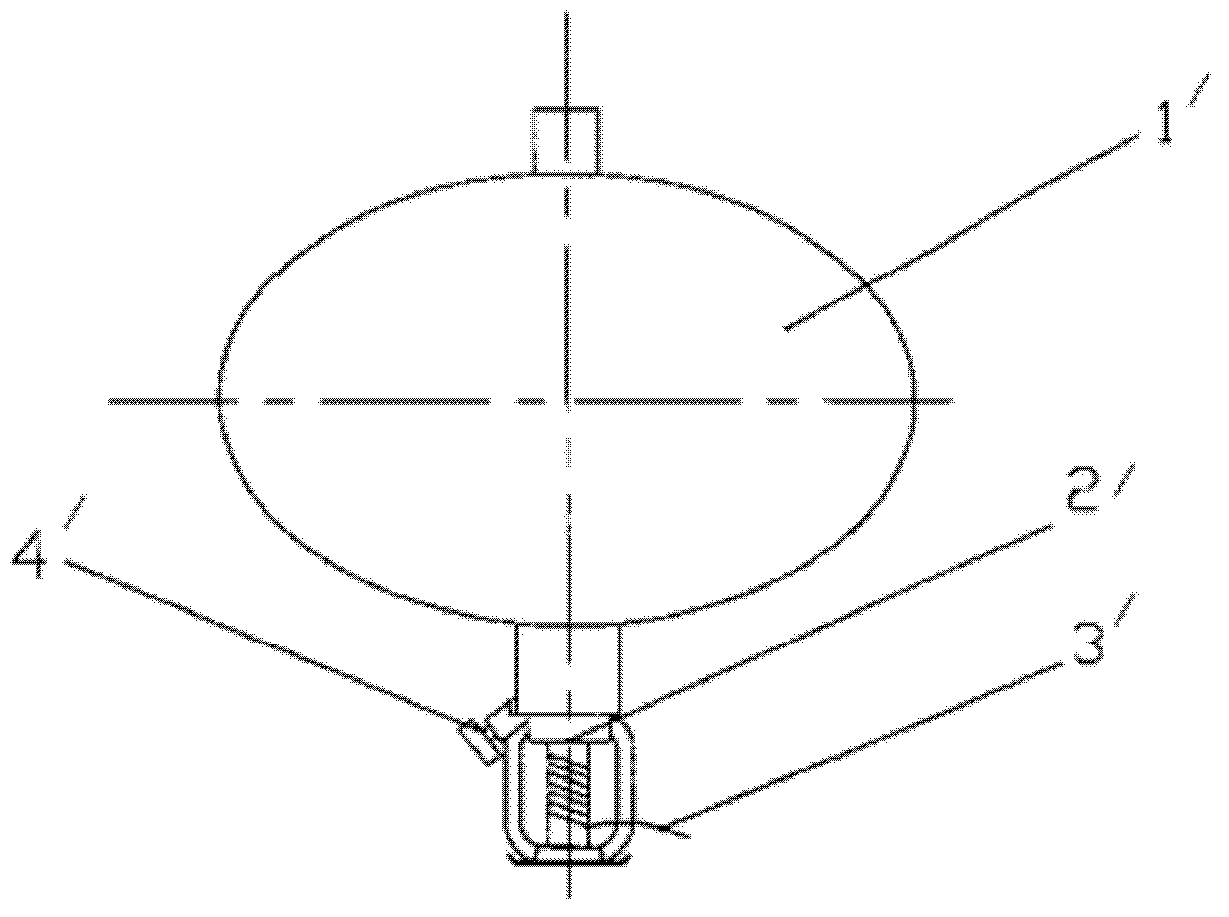

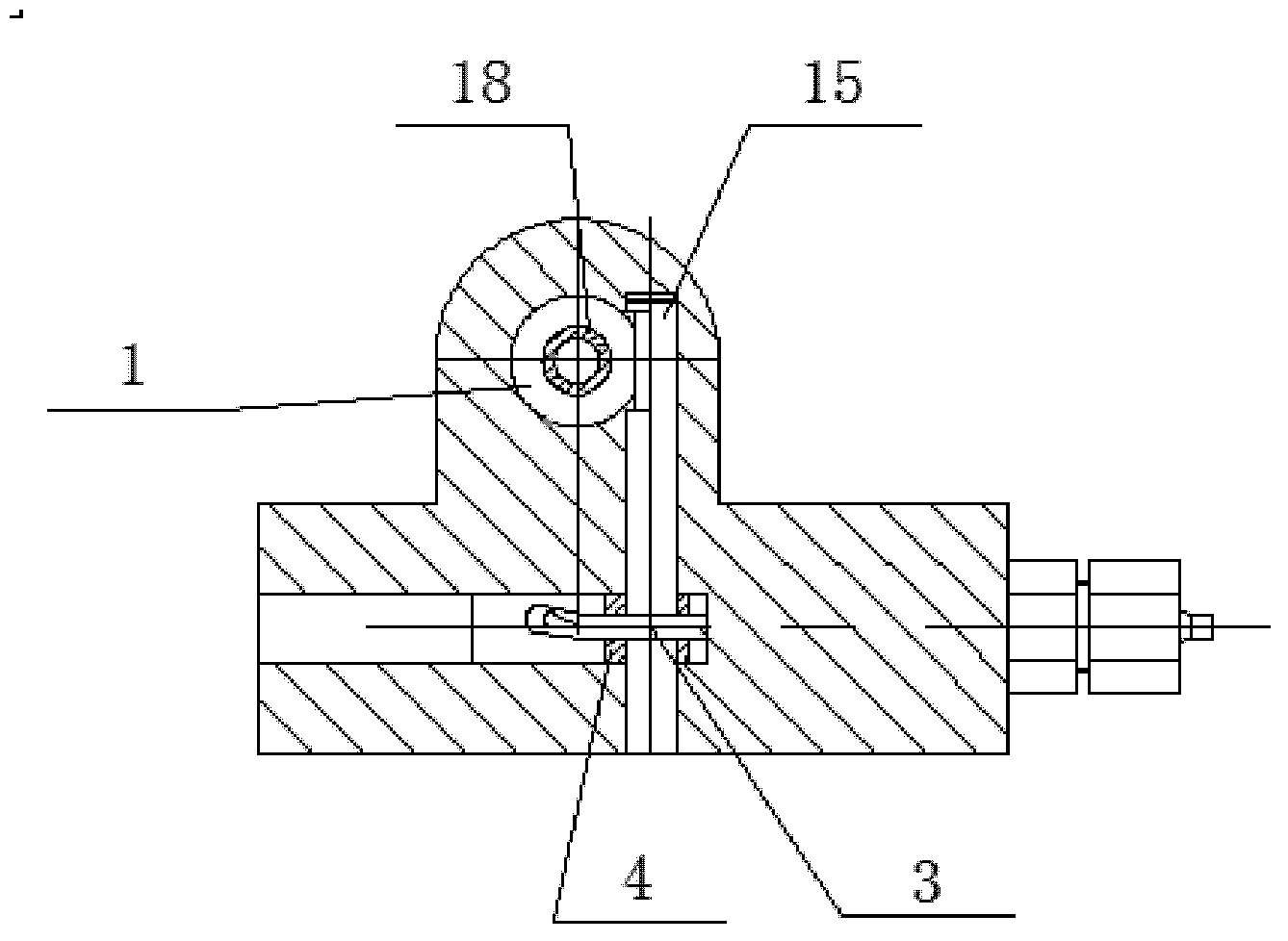

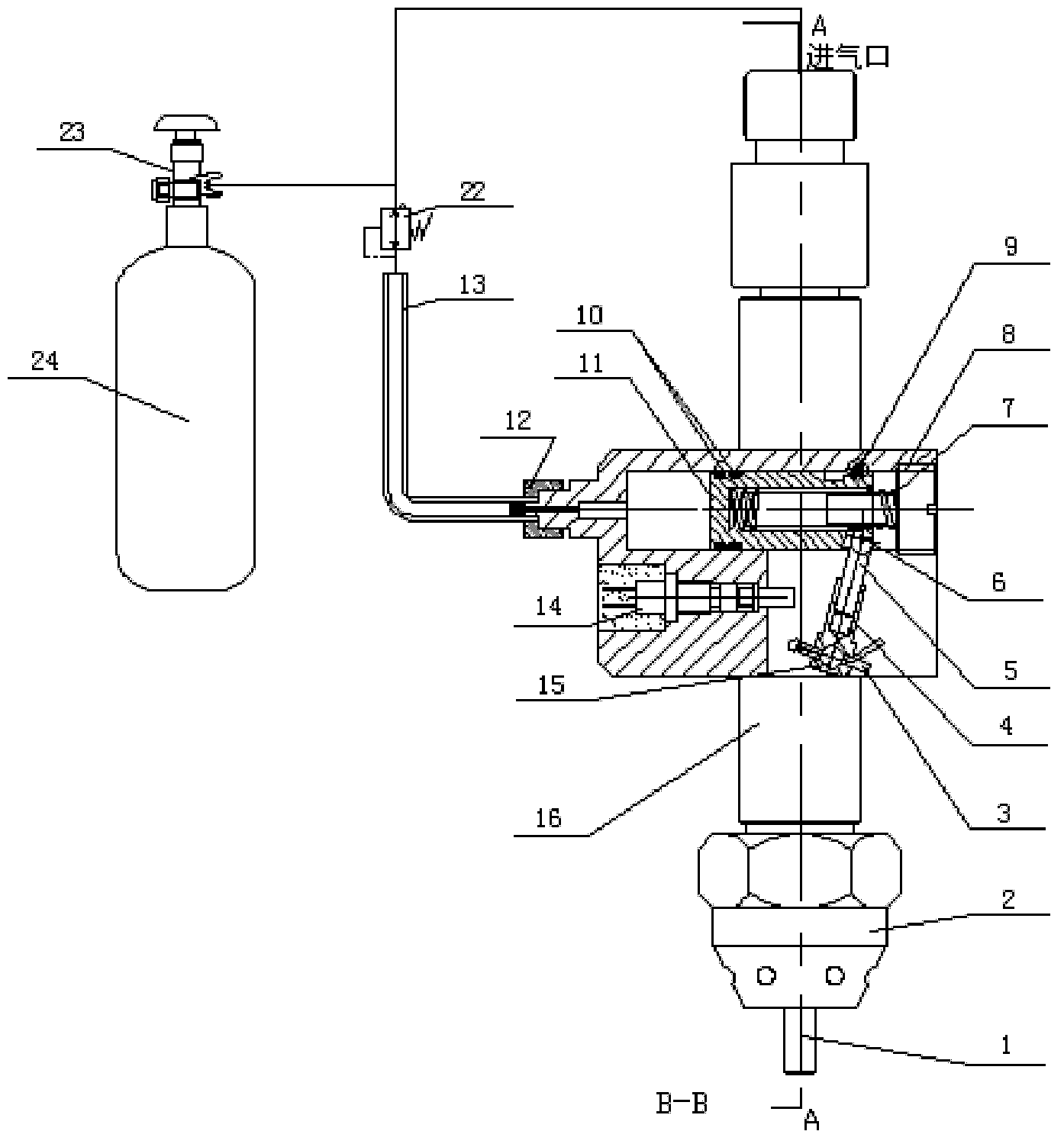

[0016] The linear temperature-sensing self-starting ultra-high pressure fire extinguishing agent release device of the present invention is suitable for gas fire extinguishing agents, see figure 2 , the tank valve 23 gas outlet pipeline of the fire extinguishing agent gas storage tank 24 is connected to the interface nut 21 of the air inlet on the upper end of the nozzle valve body 16 and the inlet end of the linear temperature-sensing detection tube 13, which is characterized in that the nozzle valve body 16 is axially The cavity is equipped with an impact body 1, a starting spring 17, and an impact cutter head 18, and one end of the nozzle valve body 16 is equipped with a nozzle 2, see image 3 , 4 , the other end is installed with a diaphragm 19, a sealing washer 20 and a connecting nut 21; figure 2 , 6 It can be seen that there are two holes on one side of the protruding part of the middle part of the nozzle valve body 1, and the gas detection pipe joint 12 is installe...

Embodiment 2

[0021] Because the linear temperature-sensing detection tube 13 is connected to the high-pressure fire extinguishing agent storage device 24, the tube wall bears a certain pressure, so the pressure range, material and manufacturing process should be considered. The easy way is to set a tank valve 23 at the outlet of the high-pressure fire extinguishing agent storage device 24, and add a pressure reducing valve 22, and then connect with the linear temperature-sensing detection pipe 13, thereby reducing the pressure of the linear temperature-sensing detection pipe 13, and also Reduce manufacturing costs. The working pressure of the air inlet end of the decompression valve 22 is 0-30 MPa, and the working pressure of the air outlet end is 0-2 MPa.

[0022] The material used in the present invention is:

[0023] 1. Linear temperature sensing tube: outer diameter 3-6mm, inner diameter 1-4mm, made of nylon, polyethylene, polypropylene and other polymer materials.

[0024] 2. Diaphr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com