Optimized design method for ship anchoring machine seat

An optimized design and machine base technology, applied in computing, special data processing applications, instruments, etc., to achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

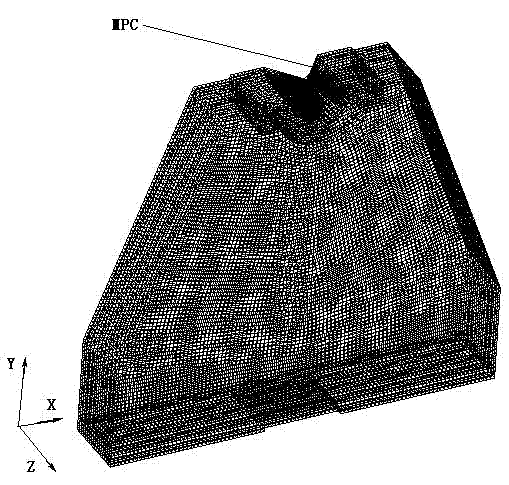

Image

Examples

Embodiment

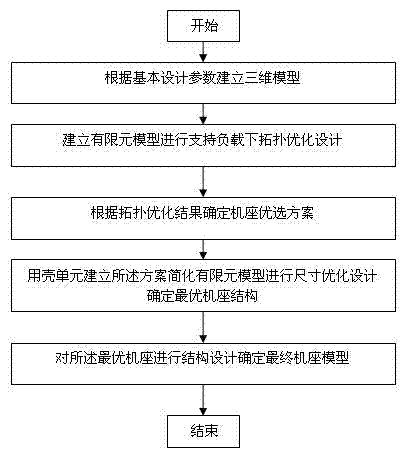

[0030] The basic design parameters of ship windlass are: anchor chain diameter φ44 (AM3); working load F C =92kN; overload tension is 138kN; anchor speed V C ≥9m / min; the number of teeth of the sprocket is 6; the diameter of the sprocket pitch circle D=φ704mm; the calculated diameter of the sprocket is D 0 =φ672mm; supporting load is 691kN; drum working load is 60kN; drum rope capacity is 180m×φ48mm (single); mooring speed is 15 m / min; negative drum tension is 30KN; hydraulic motor model is NHM31- 4000B (initial Ningbo Intem); Displacement q 0 =4153ml / r. The parameters of the pump station are: oil pump model 160SCY14-1B; motor model Y225S-4-H-B3, 37KW / 380V, 50Hz. The following is based on figure 1 The steps shown are for the optimal design of the windlass base.

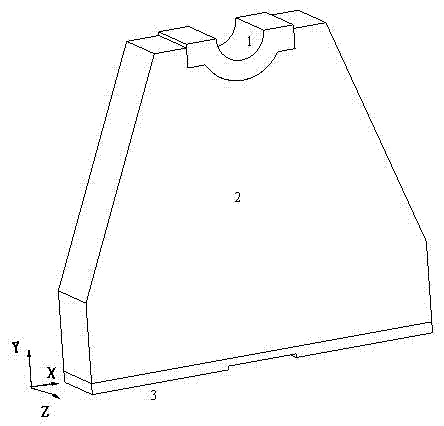

[0031] Step 1: According to the above windlass parameters, through the calculation of mechanical design, the dimensions of the base are determined as: length 1000mm, height 905mm, width 170mm, side plate slope 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap