Light irradiation device

A light irradiation device and light shielding technology, which are applied in electrical components, parts of gas discharge lamps, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult light cleaning treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

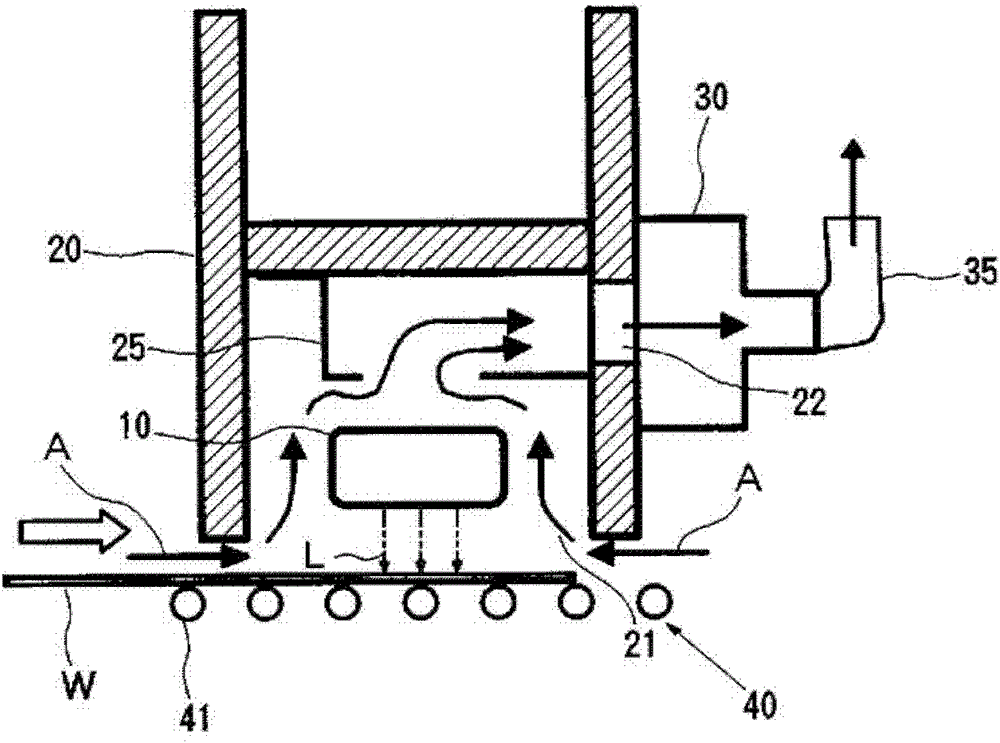

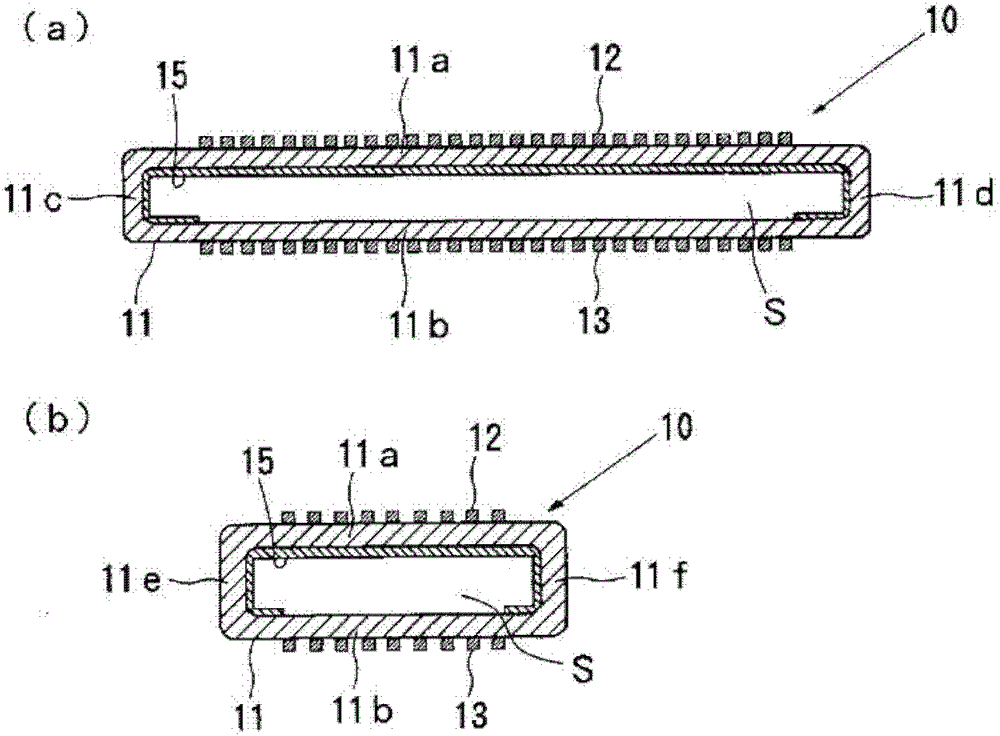

[0066] according to figure 1 and figure 2 The composition of the lampshade has a width of 160mm, a height of 250mm, a height of 100mm for the excimer lamp, and a total length (depth) of 3000mm; Light irradiation device of excimer lamp with a length of 2200mm. The excimer lamp of this light irradiation device seals xenon gas in the inside of the discharge vessel, and, as a light shielding unit, covers the upper wall of the discharge vessel and the entire inner surface of each of the four side walls and the peripheral portion of the lower wall. The inner surface forms an ultraviolet shielding film. Furthermore, a glass substrate for liquid crystal is used as the object to be irradiated, and the lamp power of the excimer lamp is 1.6kW, and the ultraviolet irradiation on the outer surface of the discharge vessel is 150mW / cm 2 , The distance between the excimer lamp and the object to be irradiated is 4mm, the gas exhaust volume is 3000l / min, and the conveying speed of the glass...

Embodiment 2

[0070] Except that the position where the ultraviolet shielding film is formed is changed to the entire outer surface of the upper wall and four side walls of the discharge vessel and the outer surface of the peripheral portion of the lower wall, a light irradiation system with the same structure as in Example 1 is made. device. In addition, a glass substrate for liquid crystal was used as the object to be irradiated, and the glass substrate was cleaned under the same conditions as in Example 1, and the contact angles of the surface of the glass substrate before and after the cleaning treatment were measured.

[0071] As a result, the contact angle of the surface of the glass substrate was 40° before the cleaning treatment, but was 2° after the cleaning treatment, and it was confirmed that a high cleaning treatment ability was obtained.

[0072] Furthermore, the light irradiation device was operated continuously for 6 months, and the cleaning treatment of the glass substrate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com