Cutting device of sugarcane harvester

A cutting device and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of broken sugarcane, small incision, low work efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

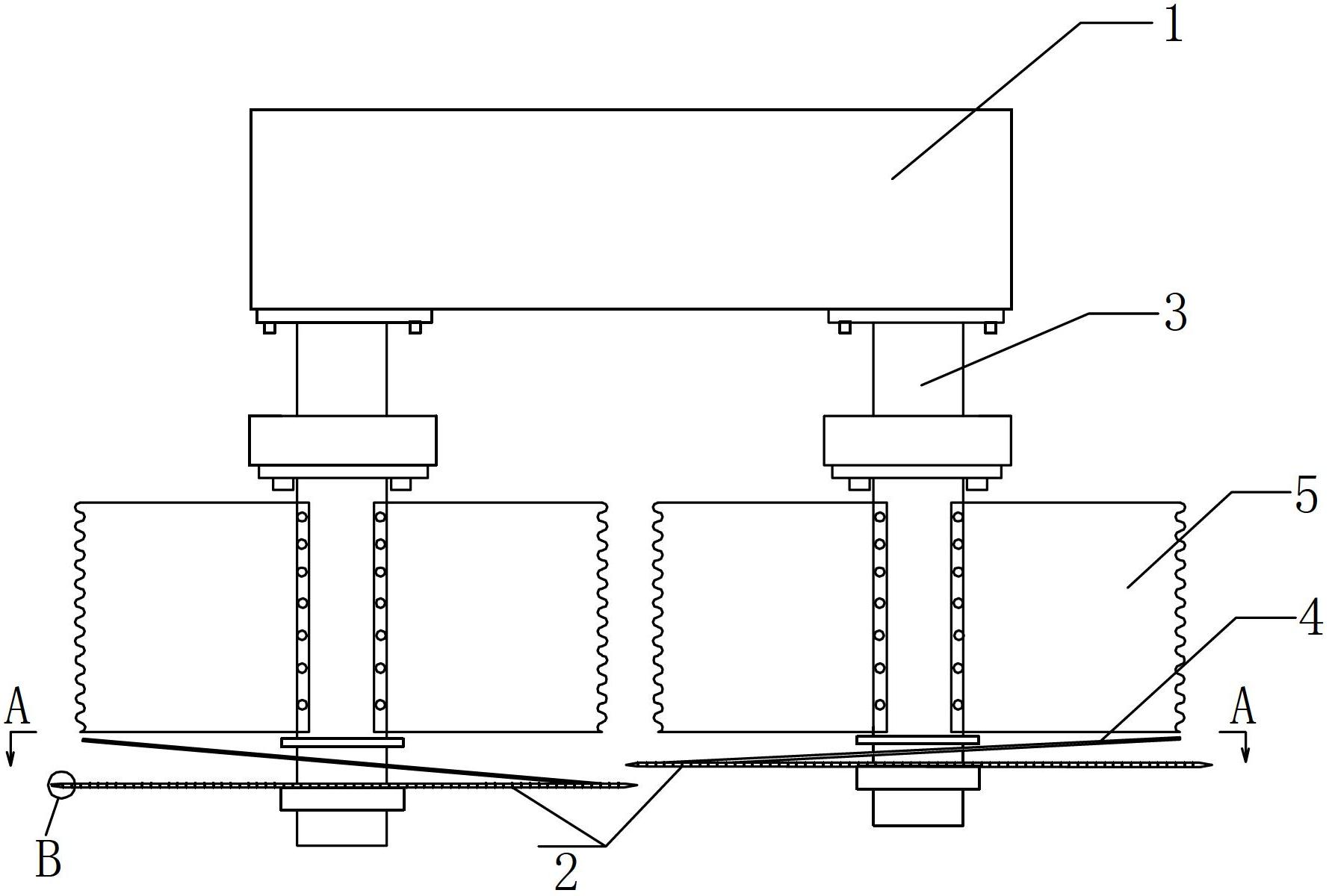

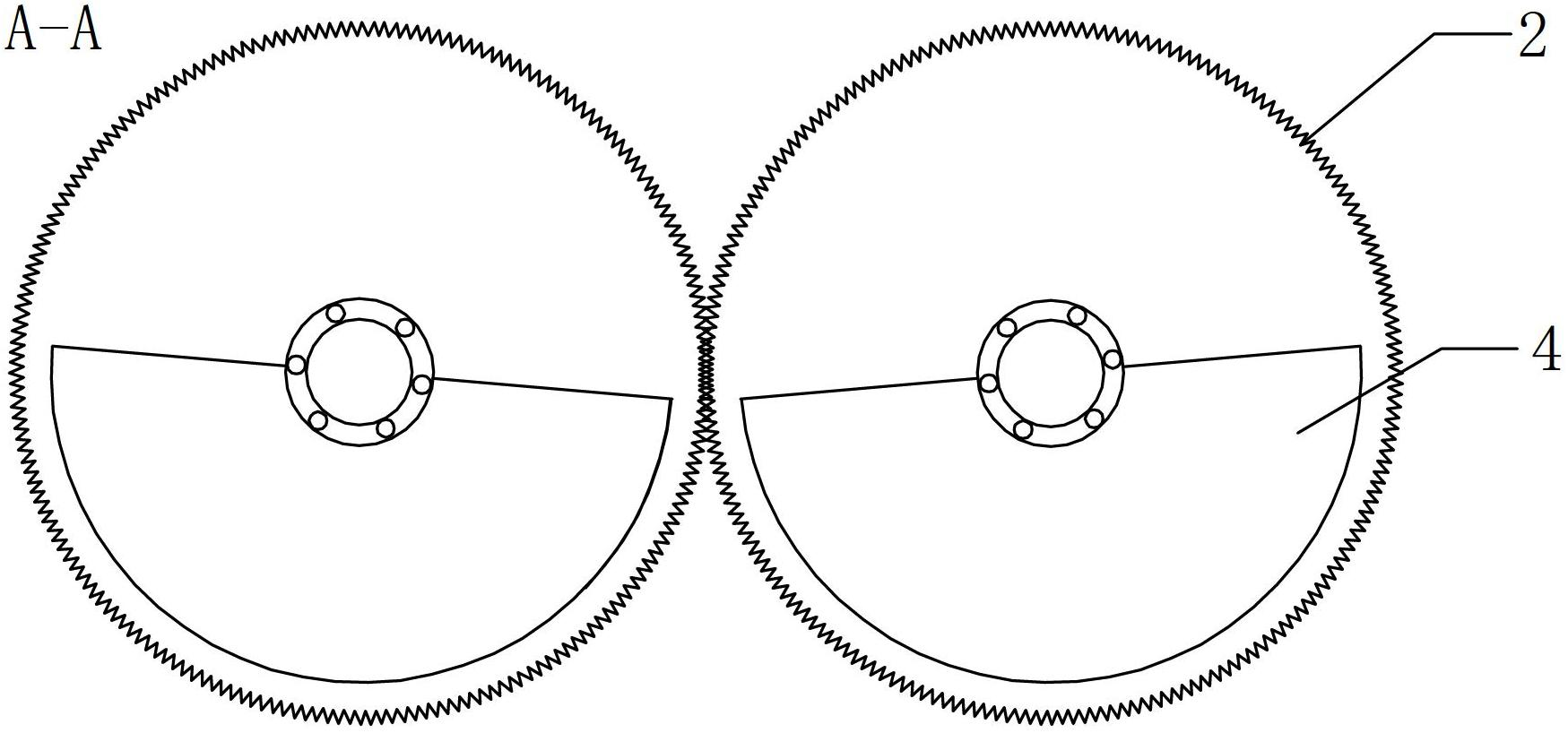

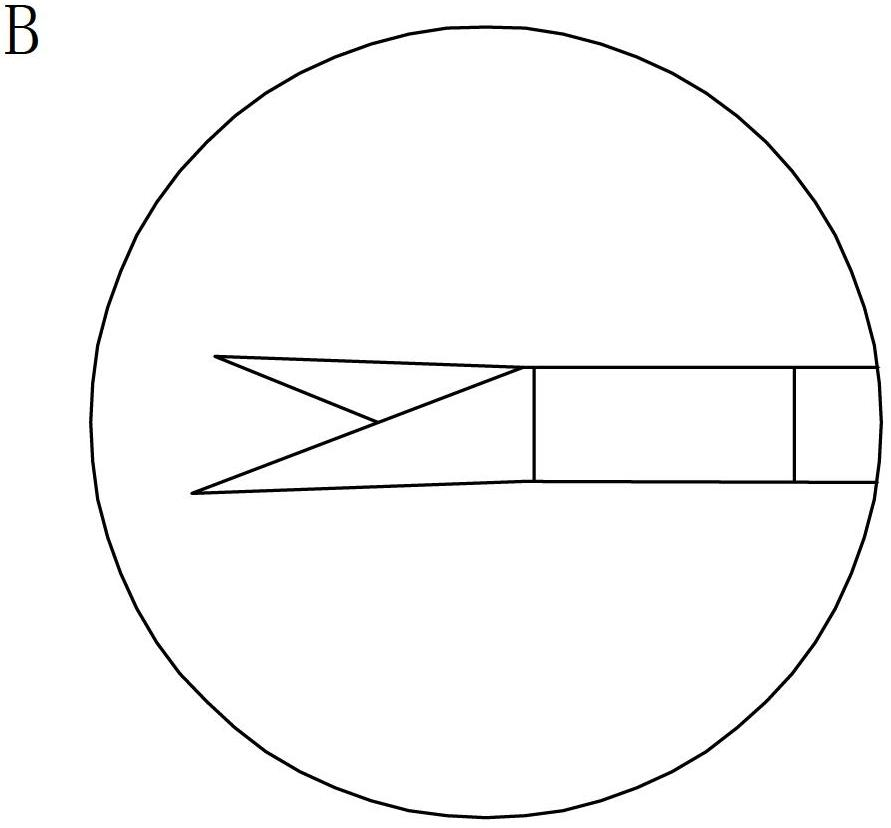

[0024] The cutting device of a kind of sugarcane harvester of the present invention, as figure 1 As shown, it includes a box body 1 equipped with a transmission mechanism, a left and right sawtooth circular cutter head 2, and a left and right transmission shaft 3. The circular cutterhead 2 rotates in the opposite direction, and the adjacent saw teeth on the sawtooth circular cutterhead 2 are misaligned up and down, such as image 3 As shown, the height difference between the upper and lower misalignment of the sawtooth tip is 0.3cm larger than that of the sawtooth circular cutter head 2. The thickness of the sawtooth on the sawtooth circular cutterhead 2 is less than the thickness of the blade body, and the toothed circular cutterhead is in the shape of a blade. The upper ends of the left and right transmission shafts 3 are respectively connected to the harvester bracket through two bearings, wherein the uppermost bearing is a tapered bearing, which is located between the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com