Tobacco trademark vertical and horizontal cutting machine

A technology of slitting machine and trademark, which is applied in the directions of sending objects, stacking receiving device, thin material processing, etc., which can solve the problems of inability to separate, falling of moving pallets, and large gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

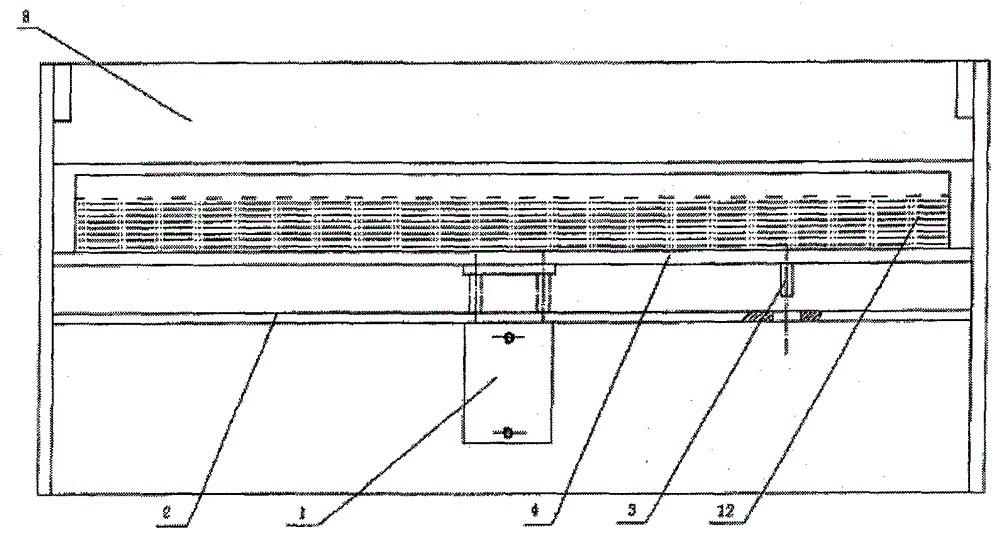

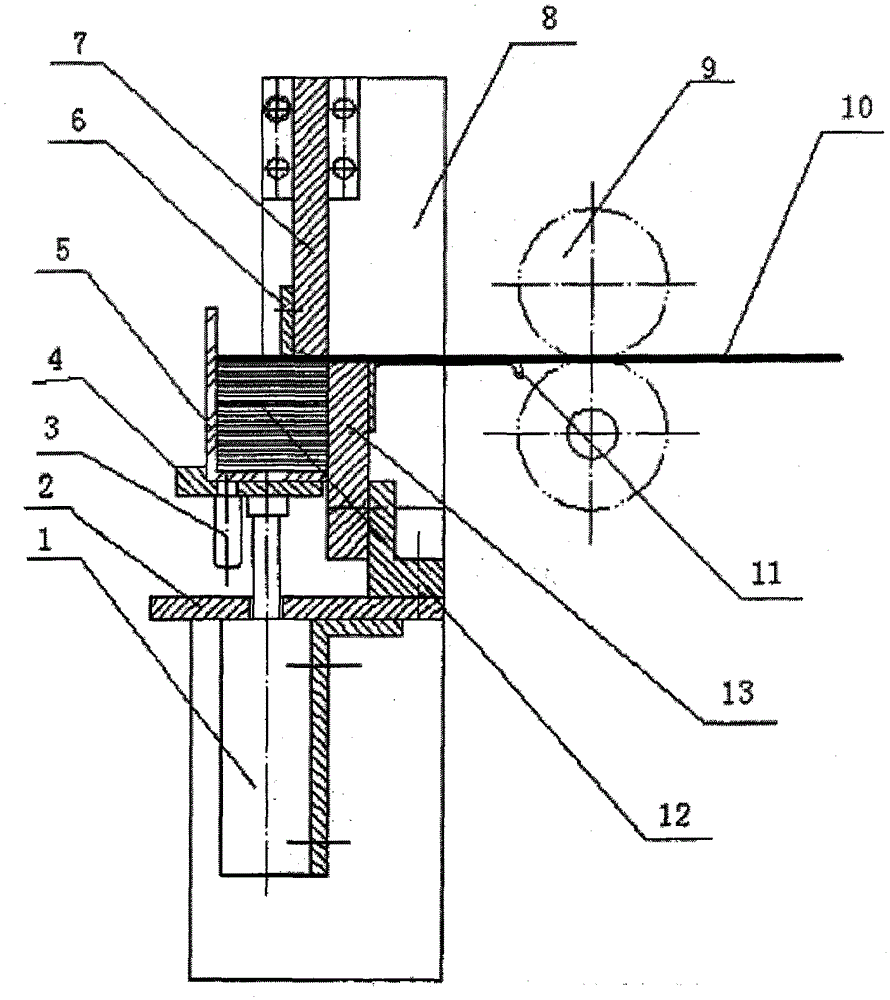

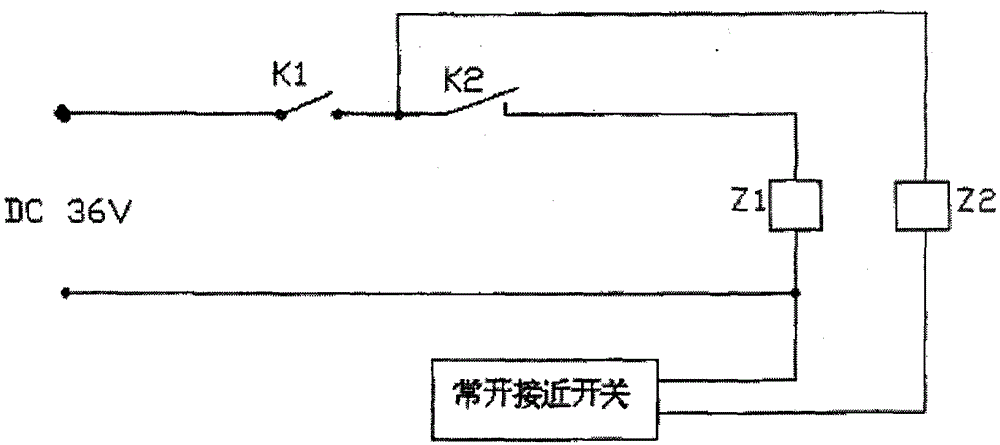

[0014] see figure 1 , figure 2 , image 3 and Figure 4 , the vertical and horizontal slitting machine for cigarette trademarks includes a slitting machine body and a damping type automatic micro-movement and quick reset labeling device; the damping type automatic micro-movement and quick reset labeling device includes a damping cylinder 1, a platen 2. Proximity sensor 3, mobile pallet 4 and L-shaped material receiving box 5; the damping cylinder 1 is fixedly installed on the platen 2 of the slitting machine body, and the cylinder body of the damping cylinder 1 is located below the platen 2; The mobile supporting plate 4 is fixedly installed on the end of the cylinder rod of the damping cylinder 1; when working, the L-shaped material receiving box 5 is placed on the mobile supporting plate 4, and the long side of the L-shaped material receiving box 5 just blocks the movement of the paper label The direction of the cut paper has fallen 12 on the short side of the L-shaped m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com