Bearing frame, shell and supporting structure

A technology of supporting structure and carrying frame, applied in the field of carrying frame, can solve the problems of inconvenient installation and disassembly of equipment, achieve the effect of convenient installation and disassembly, and avoid the use of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

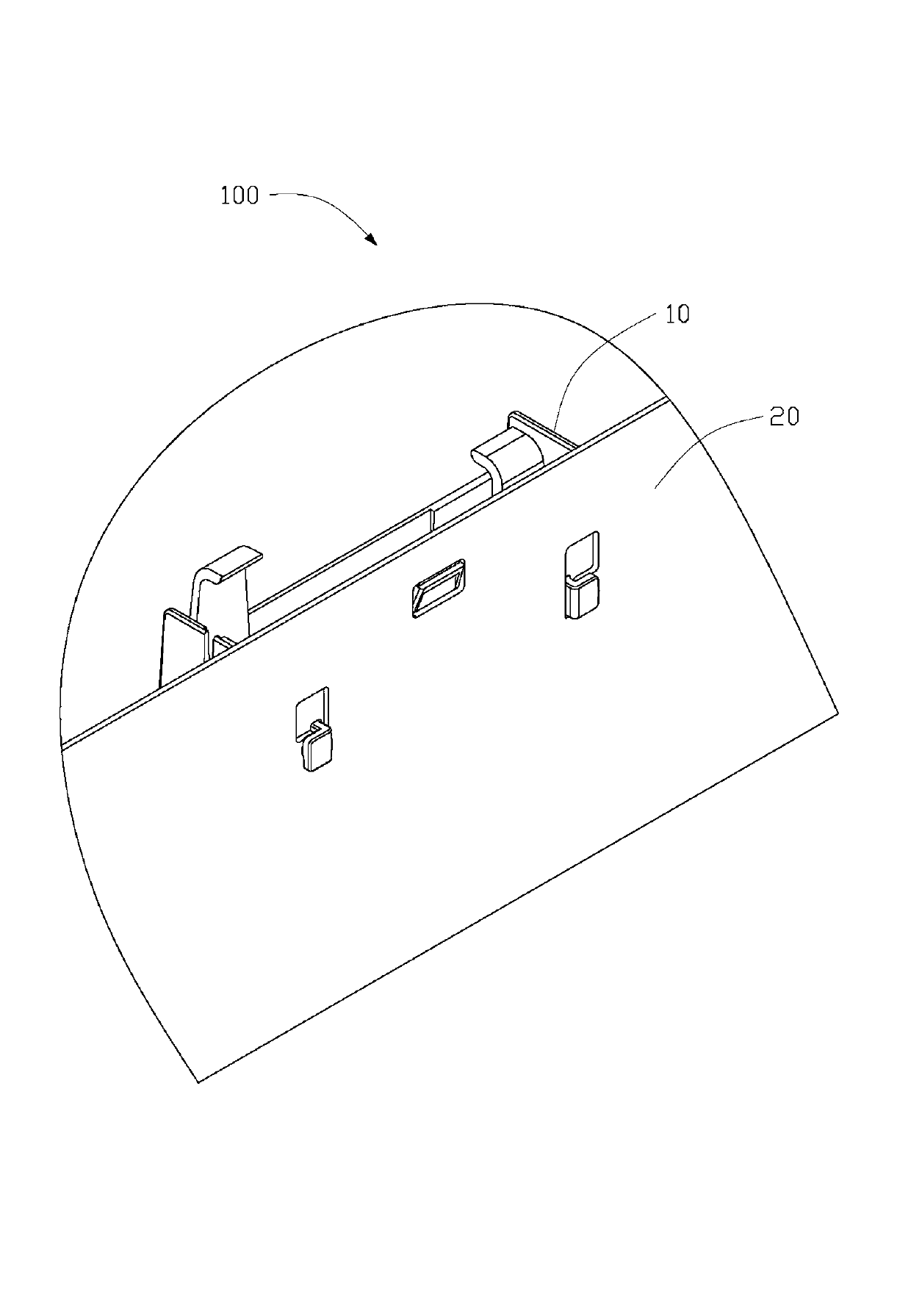

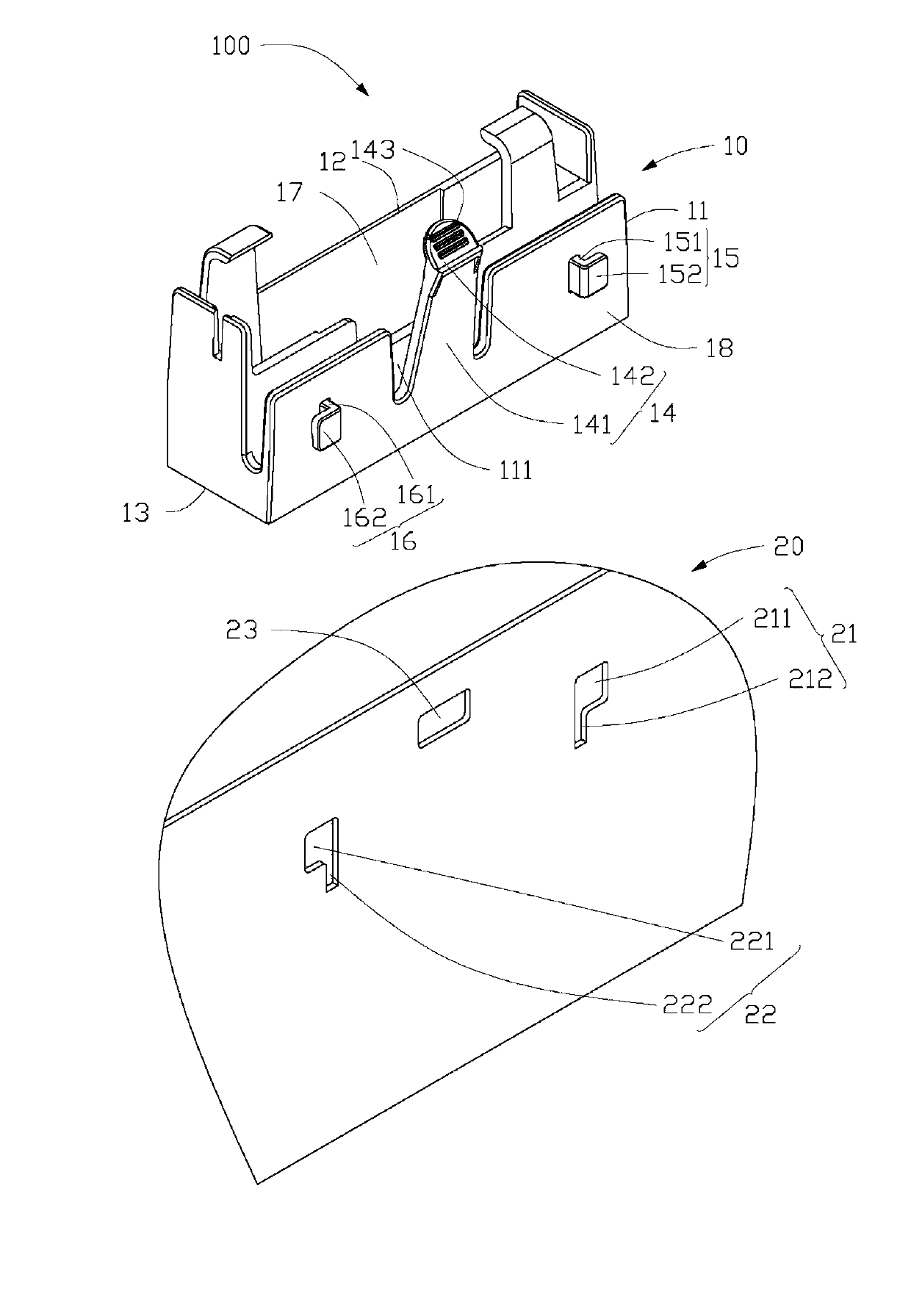

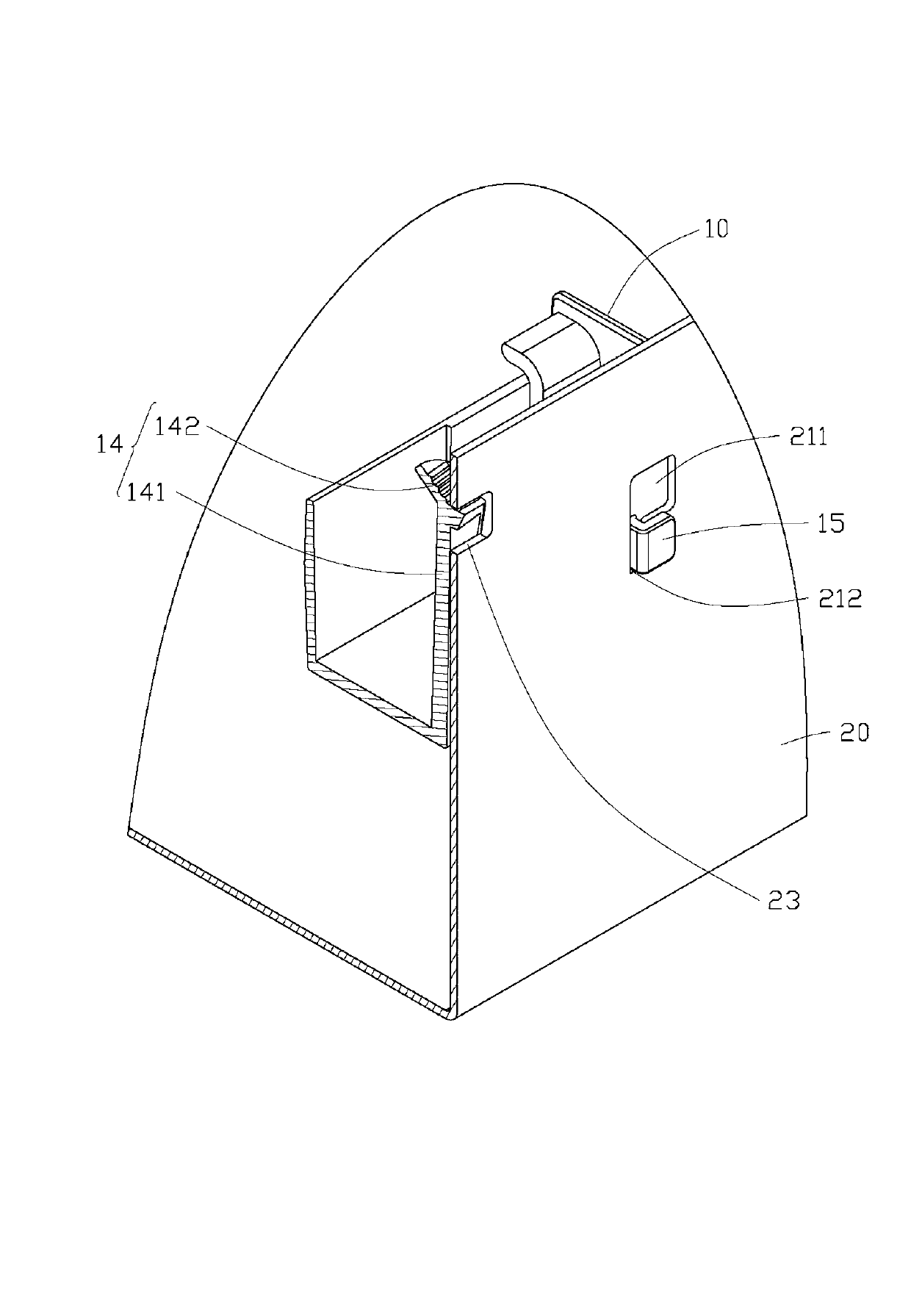

[0019] see figure 1 and figure 2 A supporting structure 100 provided in the first embodiment of the present invention includes a carrier 10 and a casing 20 , and the carrier 10 is detachably mounted on the casing 20 .

[0020] The carrier 10 includes a first side wall 11 , a second side wall 12 opposite to the first side wall 11 , a bottom wall 13 connecting the first side wall 11 and the second side wall 12 , and an elastic buckle 14 , the first guide 15 and the second guide 16 .

[0021] The first side wall 11 , the second side wall 12 and the bottom wall 13 jointly form a storage space 17 for accommodating objects (such as server power supply). The first sidewall 11 defines a notch 111 at a middle position of the first sidewall 11 .

[0022] The elastic buckle 14 and the two guides 15 , 16 are disposed on the outer surface 18 of the first side wall 11 . The elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com