Vehicle axle device

A vehicle and axle technology, applied in the direction of vehicle springs, vehicle components, elastic suspensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

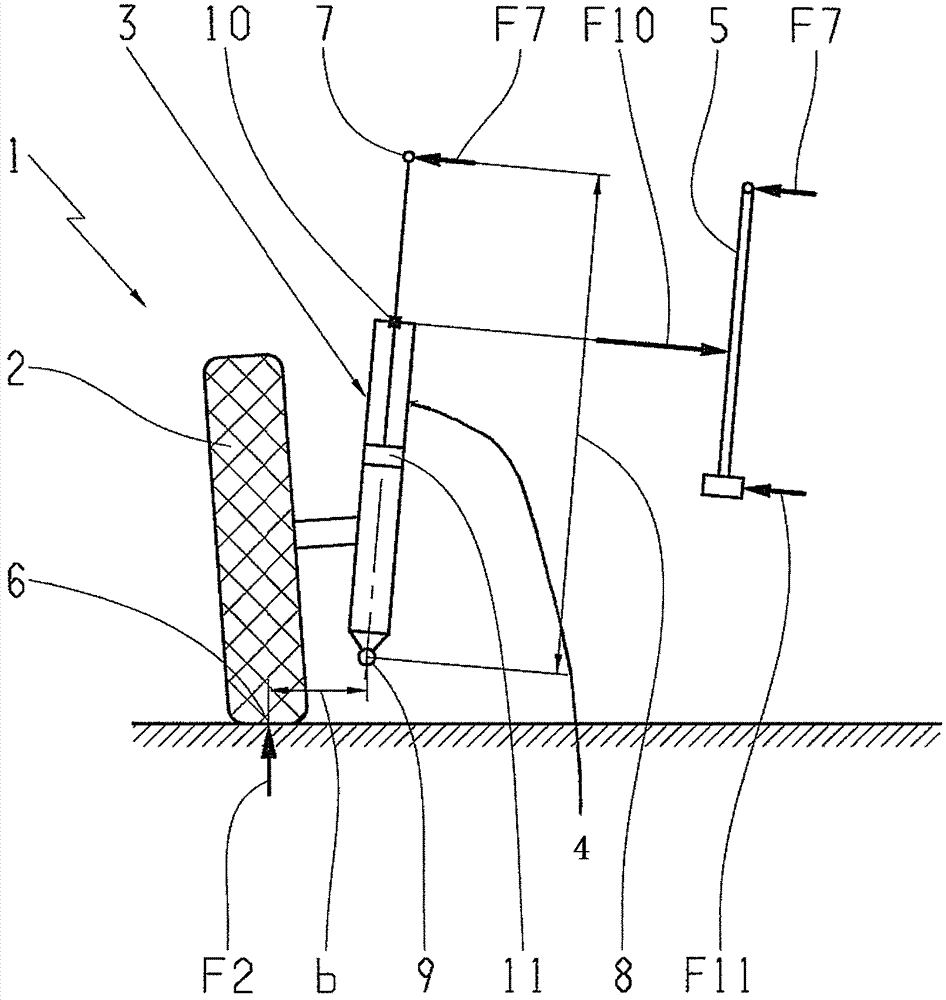

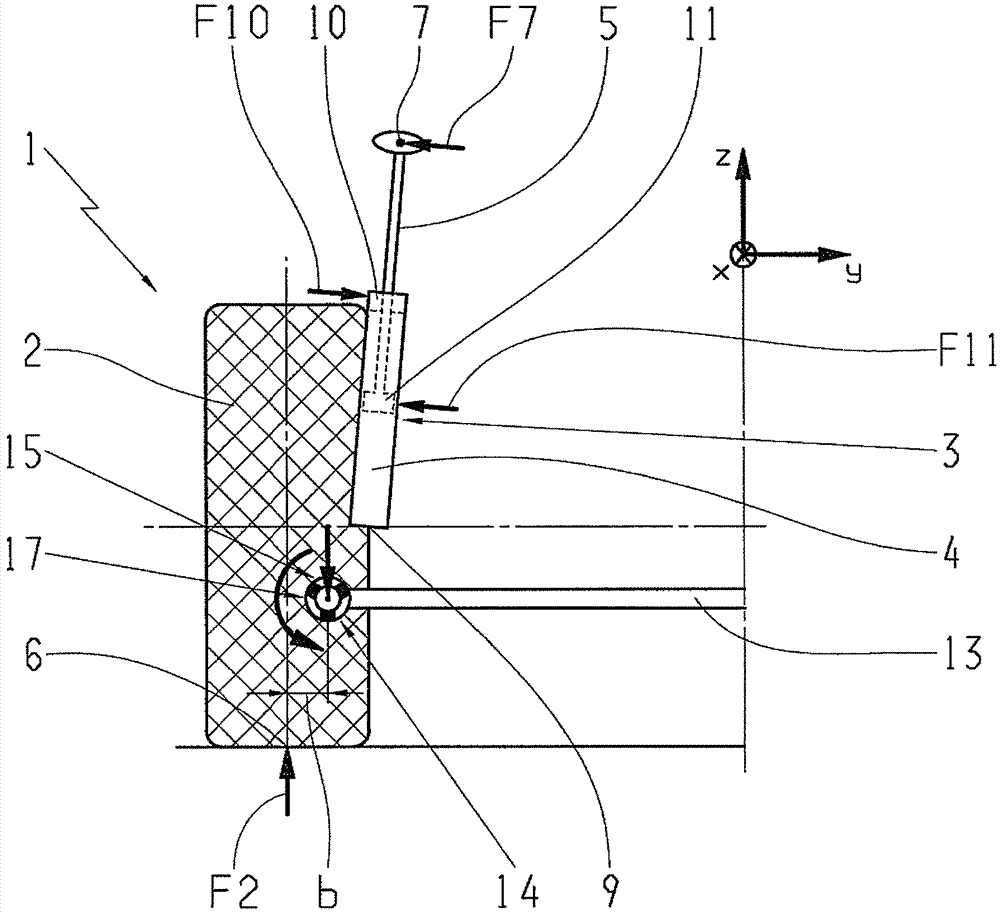

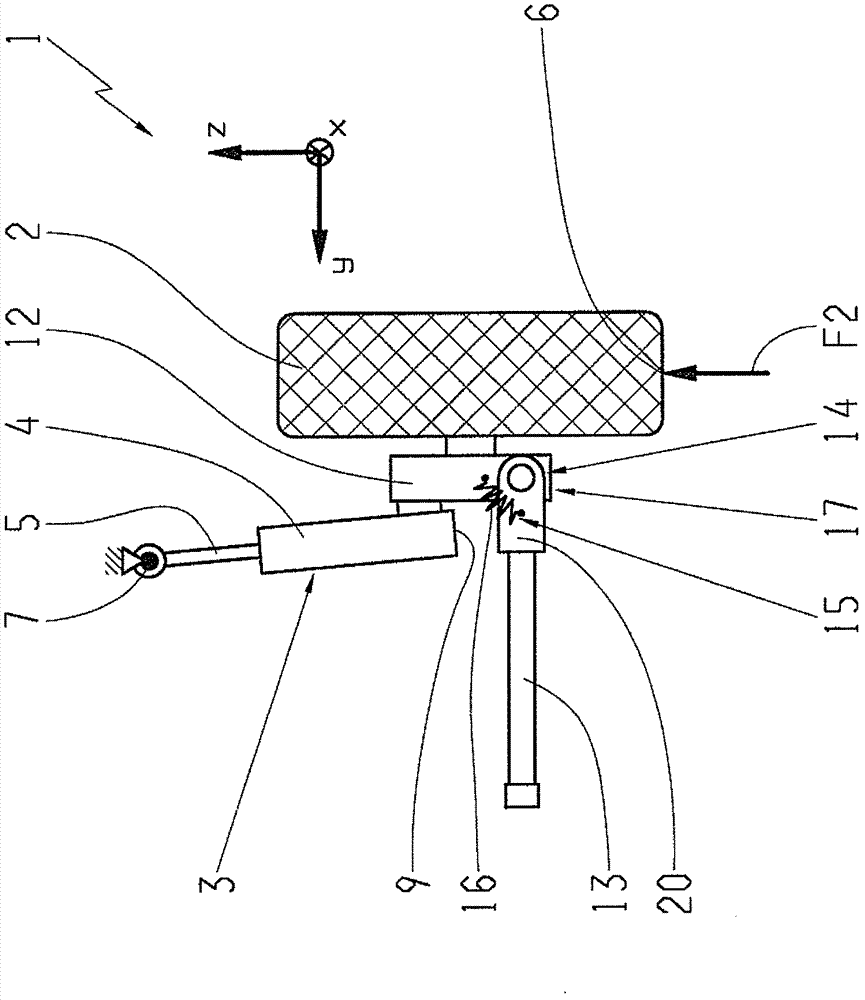

[0032] Figure 2 to Figure 6 A first exemplary embodiment of a vehicle axle arrangement 1 is shown with a wheel carrier 12 and with a transverse leaf spring extending substantially in the vehicle transverse direction y in the installed position and guiding the wheels connected to the wheel carrier 12 13 and the shock absorber strut 3 that is coupled with the wheel frame 12 and guides the wheel, wherein the transverse leaf spring 13 is in contact with the figure 2 The vehicle side opposite to the vehicle side shown in the figure is likewise connected to other wheel carriers not shown in detail in the drawings in the form and manner described in detail below.

[0033] Furthermore, the wheel 2 is fixed on the wheel carrier 12 and the spring strut 3 is arranged on the vehicle body side in the region of the end 7 of the piston rod 5 . The connection region 14 between the transverse leaf spring 13 and the wheel carrier 12 is spaced apart from the resulting force application point 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com