Engine driven two-wheeled vehicle

A technology for motorized two-wheeled vehicles and wheels, which is applied to motor vehicles, brakes, motorcycles, etc., can solve problems such as poor straddle performance, and achieve the effect of increasing the degree of freedom and improving the joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] First, Embodiment 1 of the present invention will be described based on the drawings.

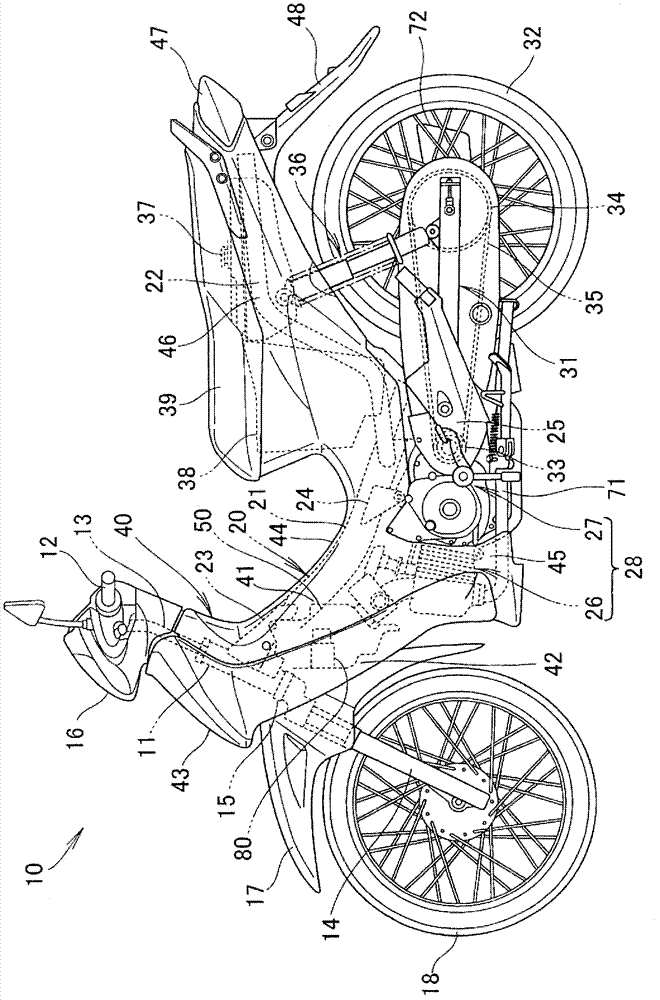

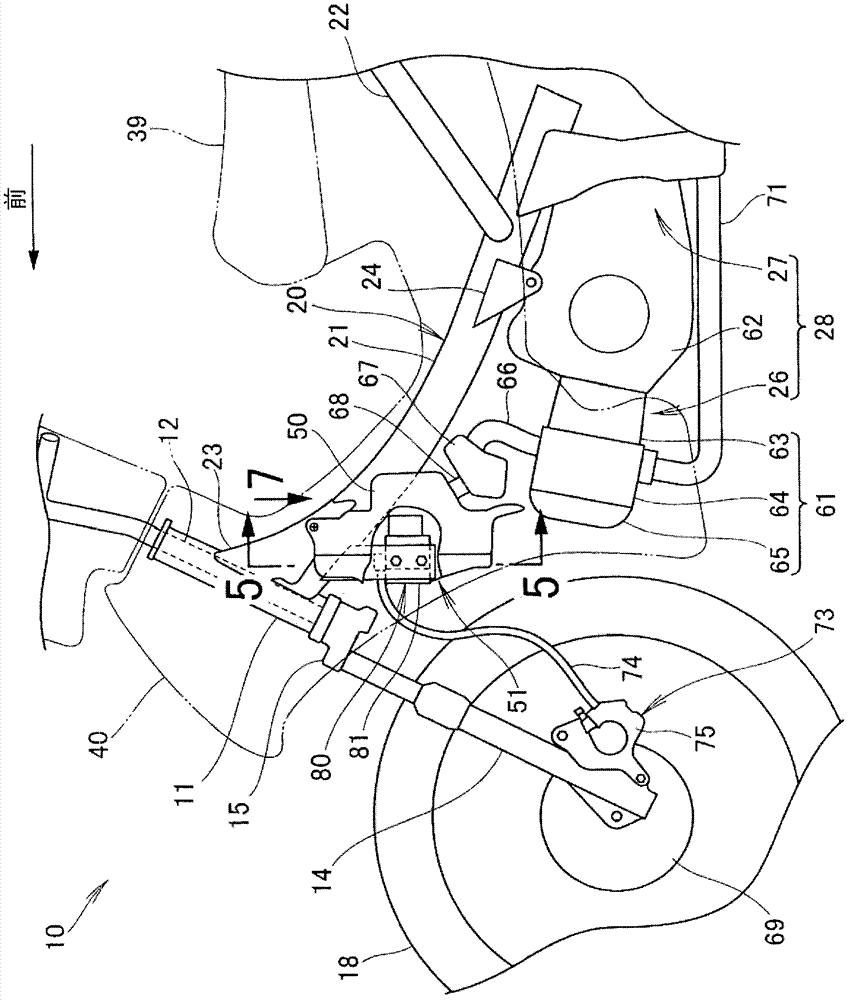

[0060] like figure 1 As shown, the motorcycle 10 has: a steering shaft 12 rotatably supported by a head pipe 11; a steering handle 13 mounted on the steering shaft 12; a brake lever 19R (refer to Figure 8 ), which is arranged near the handle 13 in this direction; the bottom bridge 15, which is installed on the lower end of the head pipe 11 and supports the upper ends of the pair of left and right front forks 14; the headlight 16, which is arranged above the head pipe 11, lights toward the front of the vehicle; and front wheels 18 (wheels 18 ) supported by front forks 14 and covered above by front fenders 17 .

[0061] In addition, the vehicle frame 20 has: a single frame 21 extending rearward and downward from the head pipe 11; a seat rail 22 extending rearward and upward from a halfway portion of the single frame 21; and a reinforcing plate 23 joined to the head pipe 11. Between...

Embodiment 2

[0107] Next, Embodiment 2 of the present invention will be described based on the drawings. and, for image 3 The same components as those shown are assigned the same symbols, and detailed description thereof will be omitted.

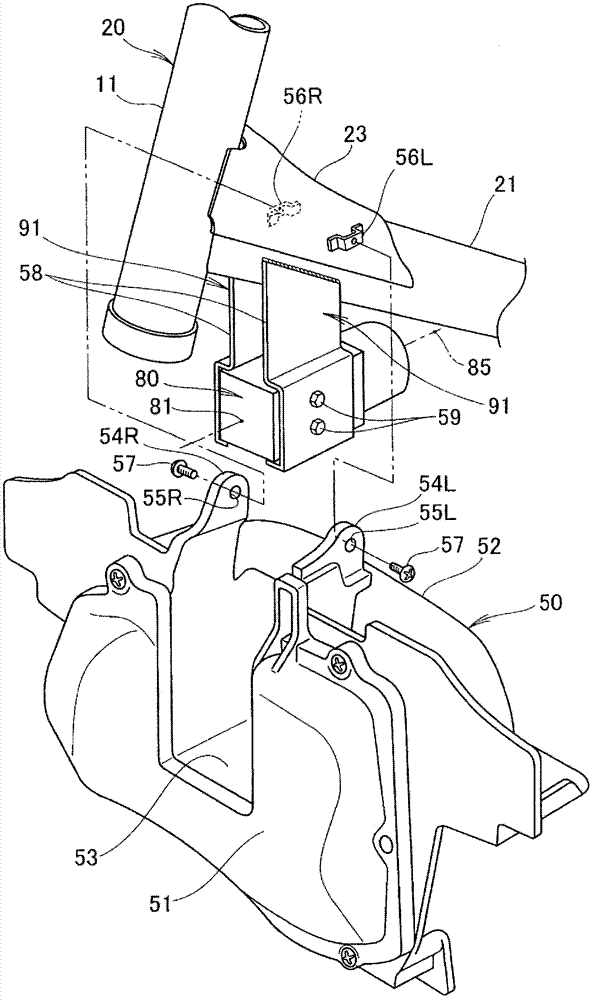

[0108] like Figure 9 As shown, the air cleaner 50 is composed of a main body 52 and a cover 51 . A recessed portion 53 is formed in the main body portion 52 , and the vehicle front side of the recessed portion 53 is closed by the cover portion 51 . The upper part of the recessed part 53 is opened, and the ABS module 80 can be accommodated in the recessed part 53 from this opening.

[0109] Next, the positional relationship between the air cleaner 50 and the ABS module 80 will be described based on a plan view.

[0110] like Figure 10 As shown, the ABS module 80 is housed in the concave portion 53 . The front of the ABS module 80 is covered by the cover part 51 . Since the front of the ABS module 80 is covered by the cover portion 51, the ABS mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com