Sensor housing and latching mechanism for sensor housing

A sensor and housing technology, applied in the field of component housing mechanisms, quick connectors or other system components, which can solve complex design requirements and increase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

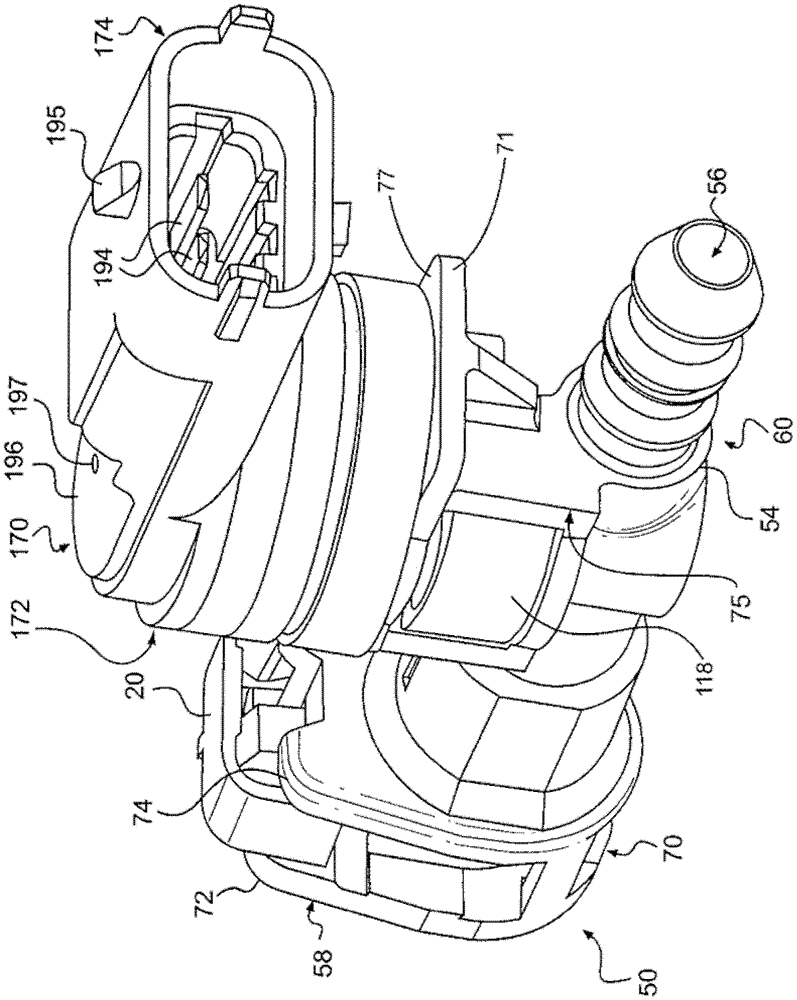

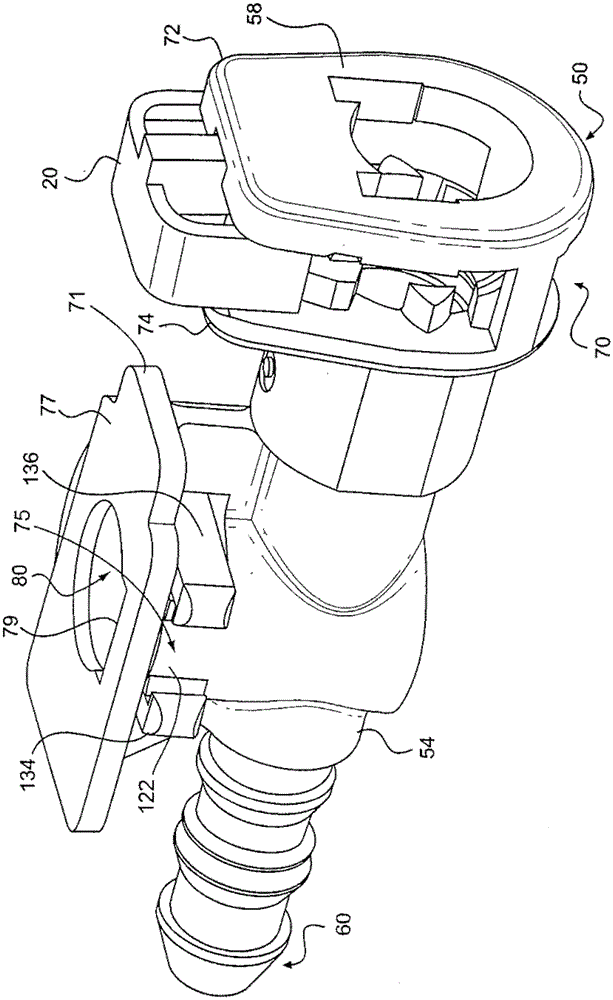

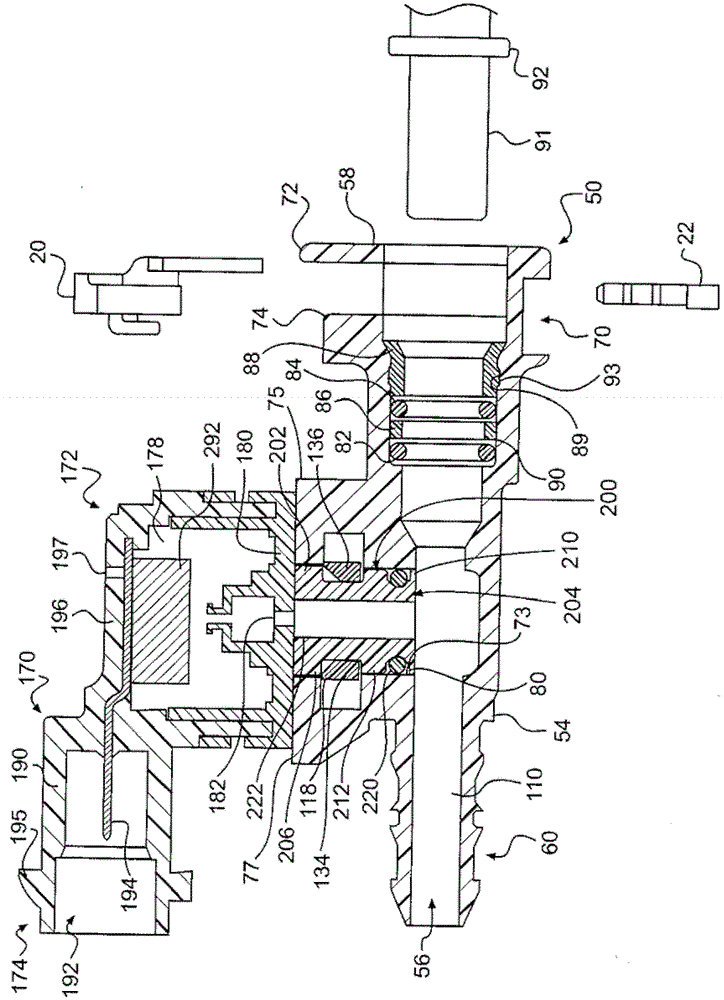

[0027] Figure 1 to Figure 11 Illustrated is a quick connector for a fluid system with an attached sensor housing that can house various mechanisms adapted to identify operating parameters of the fluid system. In its broadest aspects, the present disclosure is applicable to any element of a fluid system to which it is considered desirable to attach an induction mechanism contained within a housing.

[0028] The sensor housing may be removably attached to a mating portion on another structure, such as a quick connector body in a fuel line. An attachment mechanism may be used to secure the sensor housing to the mating part. The sensor housing is attached to the mating portion in a manner that prevents fluid leakage. The sensor disposed within the sensor housing can be any suitable sensor, such as a fluid pressure sensor or a temperature sensor.

[0029] turn to Figure 1 to Figure 3 , which illustrates the connector body 50 of the quick connector. For the purpose of illustr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com