Denitration flue reactor wallboard

A technology for reactors and nitrous flues, applied in chemical instruments and methods, building components, buildings, etc., can solve problems such as leakage, increase in production costs, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

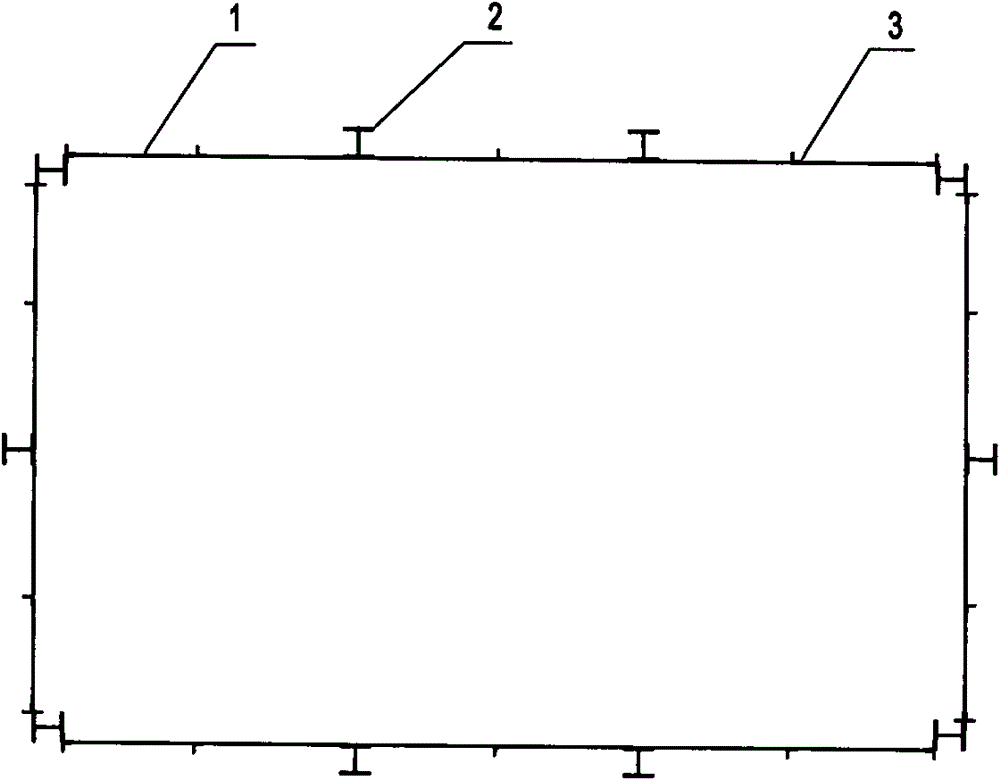

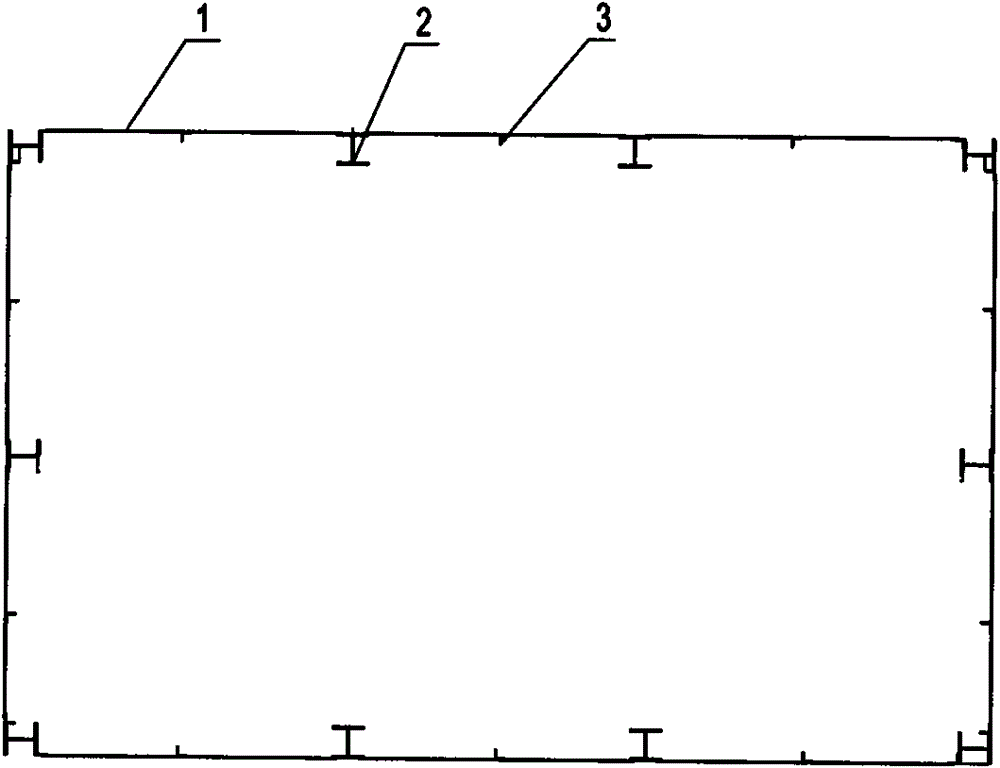

[0010] Such as figure 1 As shown, the wallboard of the denitrification flue reactor of the present invention includes a wallboard body 1, a support frame composed of a profile 2 and a profile 3, the wall panel body 1 is a steel plate, the profile 2 is an H-shaped steel, and the profile 3 is an angle steel. The supporting frame is positioned at the outside of the wallboard body 1, that is, the supporting frame made of angle steel and H-shaped steel faces the outside of the flue. The supporting frame made of angle steel, H-shaped steel and other profiles facing outward can be wrapped with external thermal insulation material, which neither affects the beautiful appearance nor hinders the normal use conditions, and can reduce production costs and save man-hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com