Measuring method for size of roll bearing block

A measurement method and roll bearing technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of measurement limitations, inability to fully reflect the real condition of bearing seat liners, high requirements for testing sites, equipment and personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

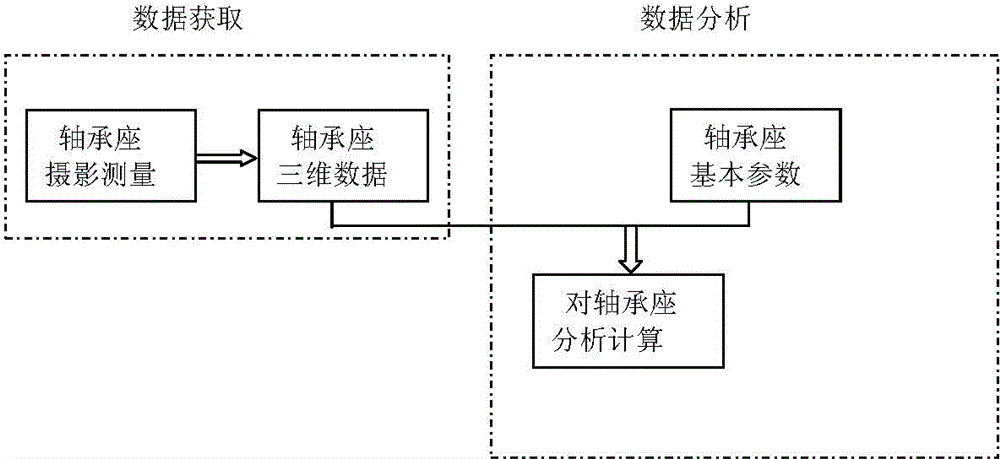

[0027] Depend on figure 1 Given, the measuring method of the present invention is as follows:

[0028] (1) Carry out digital close-range photogrammetry with a camera for the bearing seat to be inspected, obtain the measured three-dimensional point data on the surface of the bearing seat, and obtain the three-dimensional data of the bearing seat. The method is: A. Arrange photogrammetry on the two liners of the bearing seat to be inspected Use circular reflective signs (such as figure 2 ), the surface of the bearing seat is composed of two liner planes on the left and right ( Figure 5 ), the front and rear two cavity circles ( Figure 6 ), as well as the upper and lower surfaces, 25-50 circular reflective marks and 8-16 coded marks are arranged on the surface of the left and right liners of the bearing housing to meet the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com