Fully mechanized caving top coal caving three-dimensional simulation experiment method

A simulation experiment and top-coal technology, applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems of the space position optimization of the top-coal tracker to make judgments, not well avoided, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

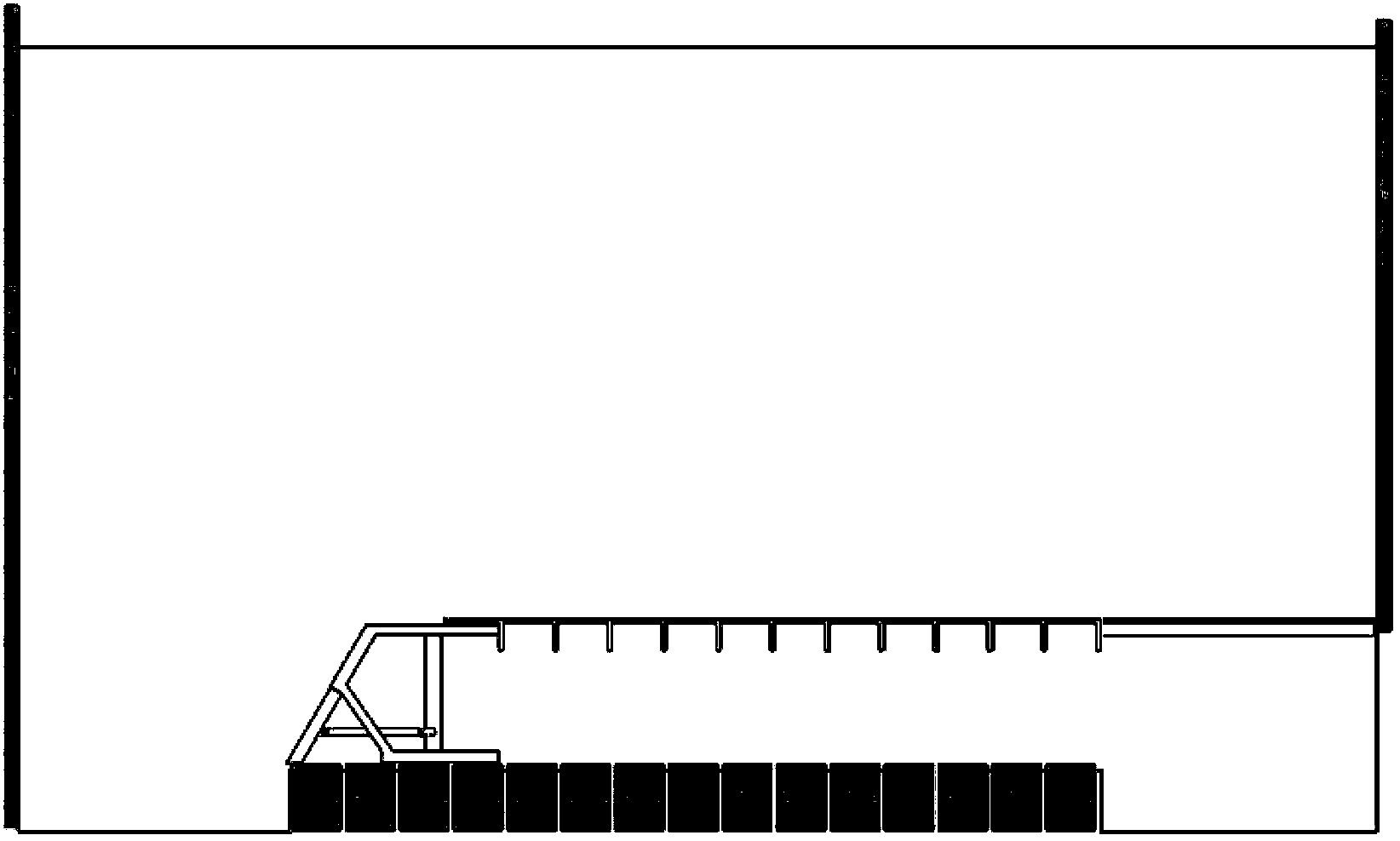

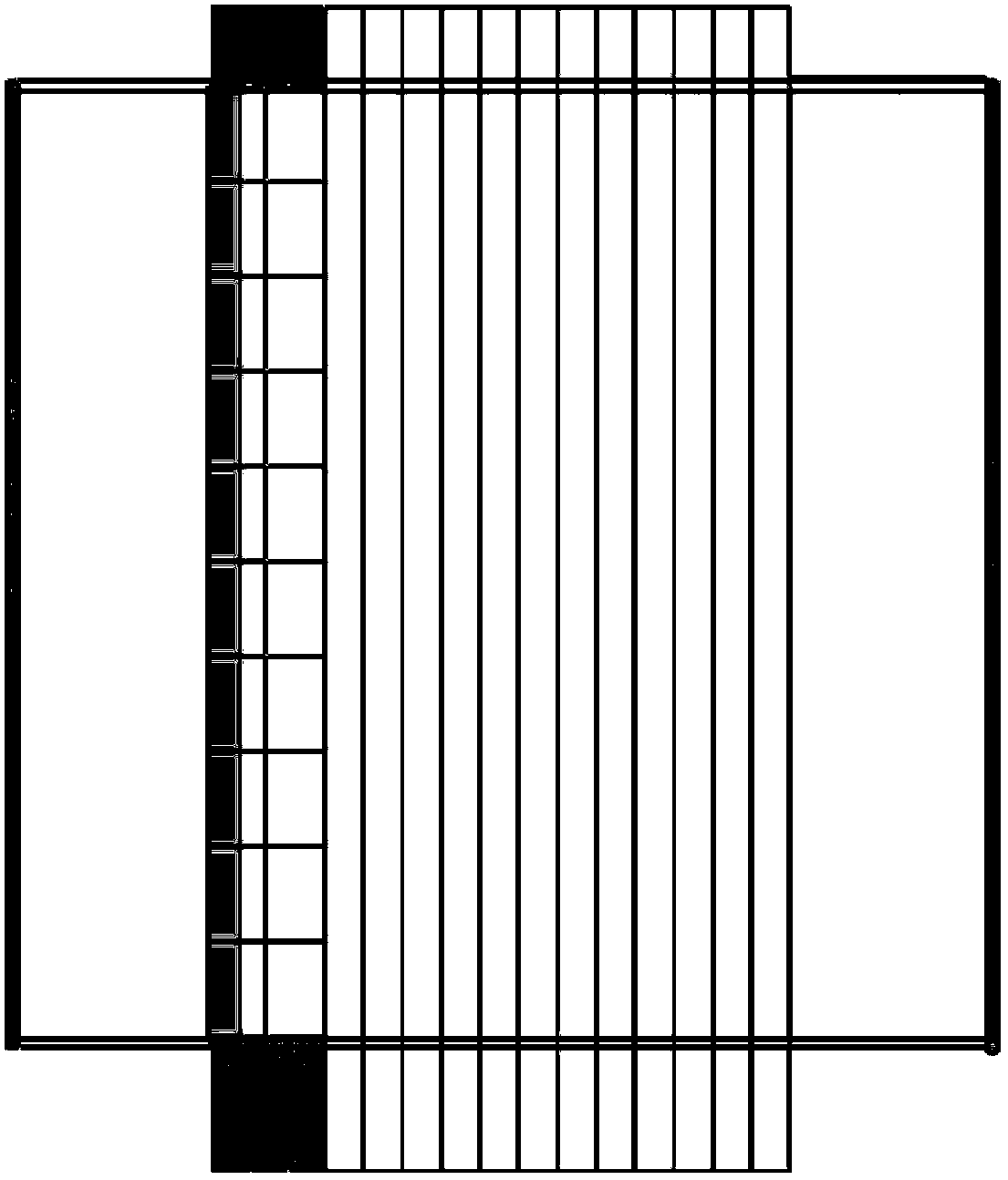

[0044] Refer to attached Figure 4 , a three-dimensional simulation experiment platform for top-coal discharge in fully mechanized caving mining according to the present invention, which comprises a combination of plexiglass plates 1 arranged at the front and rear and metal plates 2 on the left and right to form a box body, and the setting of transparent plexiglass plates is convenient for observing changes in coal discharge form , the casing is provided with a twitchable bottom plate 5, a fully-mechanized stacking support 3 that can move on the twitchable bottom plate 5, and a fully-mechanized stacking support 3 is close to a twitchable direct top 4 that is arranged in parallel with the twitchable bottom plate 5; The brackets 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com