Axis odontoid screw sighting device

A technology of odontoid process and aimer, which is applied in the field of medical devices, can solve the problems of screw breakage, large operation randomness, injury to the spinal cord, etc., and achieve the effects of easy control of direction, reduction of repeated needle insertion, and improvement of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

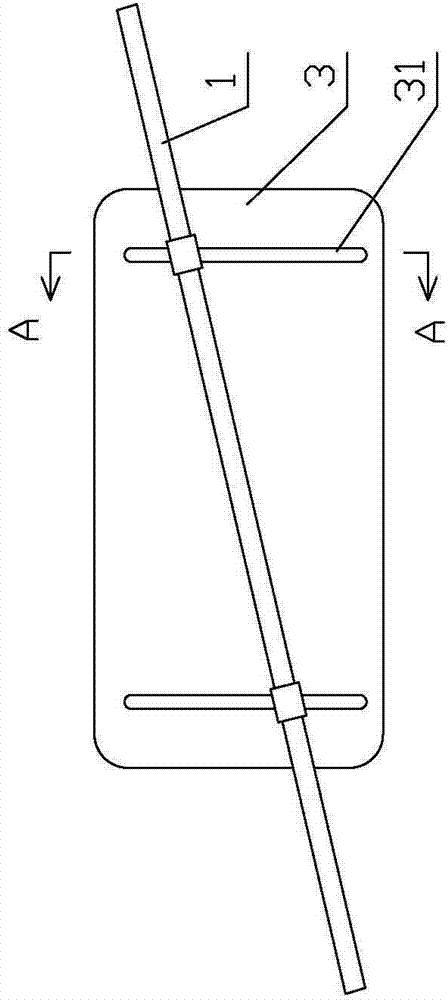

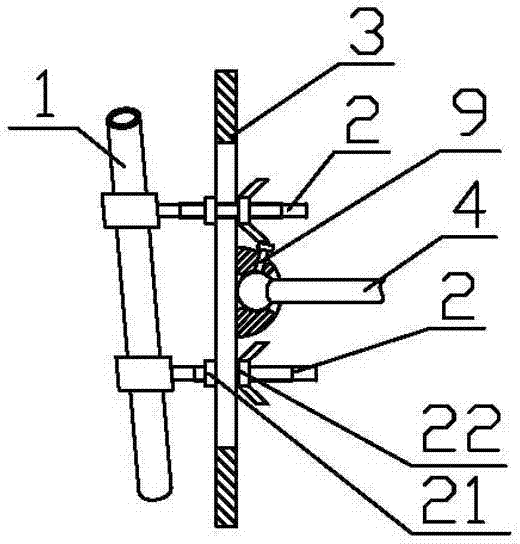

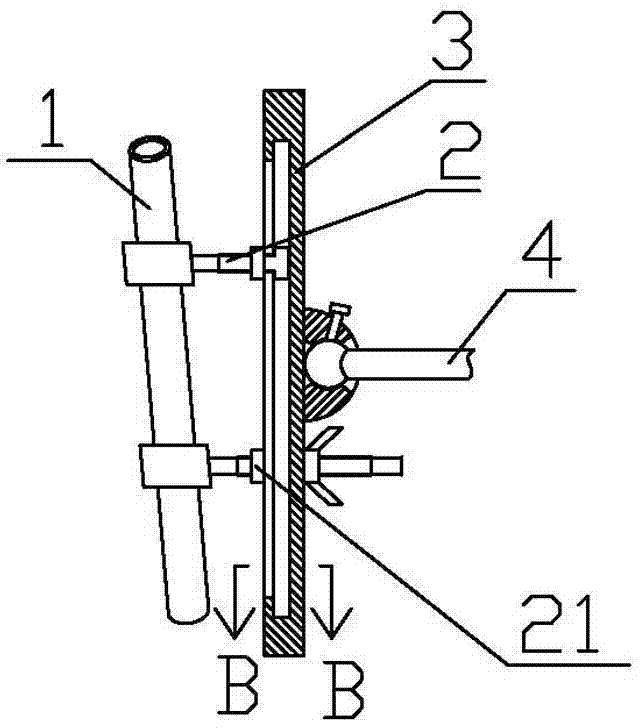

[0016] Such as figure 1 As shown, the pivot bevel dentate screw collimator of the present invention includes a hollow guide tube 1, and the hollow guide tube 1 is equipped with at least two telescopic connecting rods 2, and one end of the telescopic connecting rod 2 has a tube The hollow guide tube 1 is inserted into the tube sleeve, and the other end of the telescopic link 2 is connected to the fine-tuning control board 3. The fine-tuning control board 3 is connected to the support rod 4 through a ball joint, and the ball joint can adopt an interference fit. Install, utilize frictional force to fix the position of fine-tuning control board 3 and support bar 4, also can be as figure 2 As shown, a fastening screw 9 is installed on the ball joint, the angle of the ball joint can be freely adjusted by loosening the fastening screw 9, and the ball joint can be fixed by tightening the fastening screw 9. Support bar 4 is connected on the support, and described support can be fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com