Arm section of truss arm, truss arm and crane

A lattice boom and crane technology, which is applied in the field of construction machinery, can solve the problems such as the failure of the lattice boom to exert its bearing capacity well, and achieve the effects of easy connection, flexible setting position, and convenient setting position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

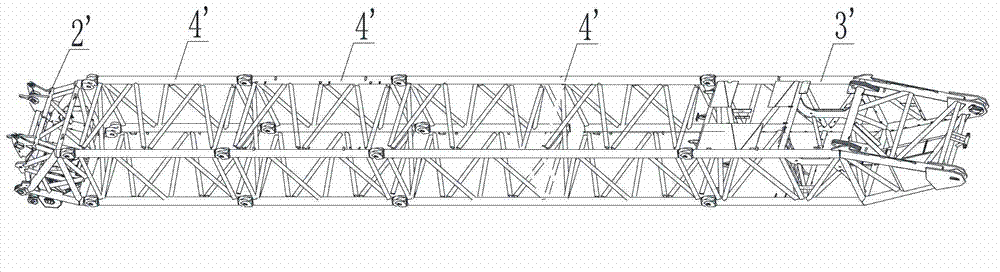

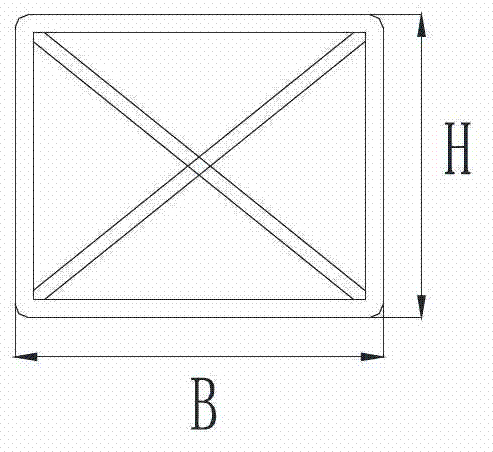

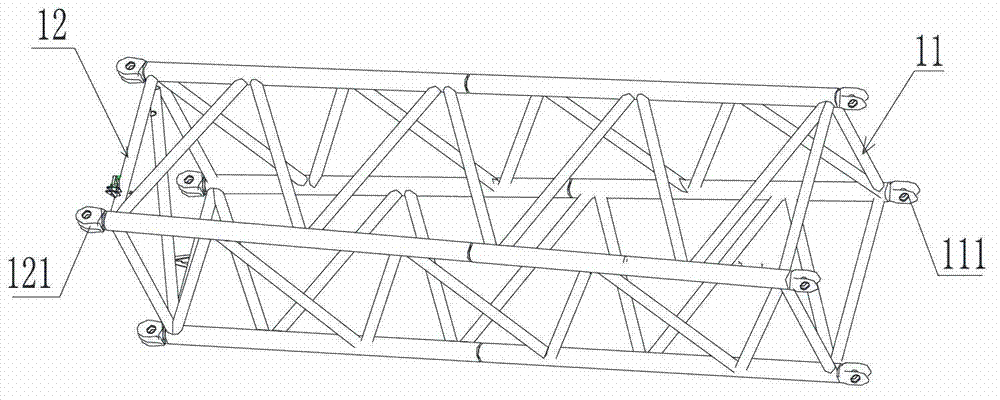

[0041] The reason why the existing lattice arms are difficult to apply to various working conditions is that the stability of the lattice arms in different directions is related to the aspect ratio of its overall section, but the adjustment space of the width and height of the section of the existing lattice arms is small, Often limited by the size and specification of the intermediate arm. To solve this problem, the present invention considers to rotate some of the existing intermediate arms by 90° and install them in the truss arm, and to change the aspect ratio of the overall section of the truss arm by using the difference in the aspect ratio of the intermediate arm section before and after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com