Light-emitting diode (LED) tunnel lamp adopting extruded radiator structure

A technology of LED tunnel lights and LED light bulbs, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc. Difficulties and other problems, to achieve the effect of facilitating standardized large-scale production, reducing the glare problem of tunnel lighting, and improving mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

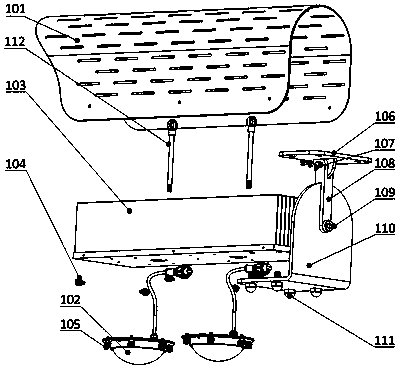

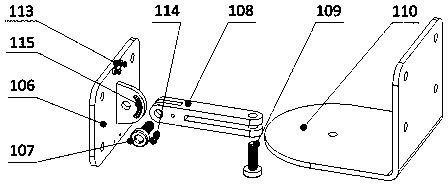

Embodiment 1

[0065] The bulb 102 is an LED bulb with waterproof and dustproof functions.

[0066] The composition method of the LED light bulb with waterproof and dustproof functions: by bonding the optomechanical module on a metal heat-conducting bracket with a flange, surrounding the edge of the optomechanical module with a ring-shaped non-metallic bracket, and placing the The bracket liner is fixed on the heat conduction support, and the light bulb components are installed with the heat conduction support and the support liner as the center of the bulb structure to form an LED bulb, so that the structure between the optical machine module and the heat conduction support is simple and flat, which is beneficial to the heat dissipation of the LED; The optomechanical module consists of an optomechanical template, LED chipset and related circuits through solid crystal and packaging, or a power supply driver chip is integrated in it, and the LED bulb is installed on the installation interface ...

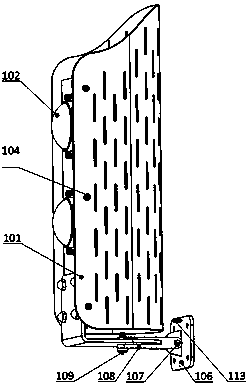

Embodiment 2

[0071] The bulb 102 is an LED bulb with waterproof and dustproof functions.

[0072]The composition method of the LED light bulb with waterproof and dustproof functions: by bonding the optomechanical module on a metal heat-conducting bracket with a flange, surrounding the edge of the optomechanical module with a ring-shaped non-metallic bracket, and placing the The bracket liner is fixed on the heat conduction support, and the light bulb components are installed with the heat conduction support and the support liner as the center of the bulb structure to form an LED bulb, so that the structure between the optical machine module and the heat conduction support is simple and flat, which is beneficial to the heat dissipation of the LED; The optomechanical module consists of an optomechanical template, LED chipset and related circuits through solid crystal and packaging, or a power supply driver chip is integrated in it, and the LED bulb is installed on the installation interface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com