LED street lamp with extruded heat sink structure

A technology of LED street lamps and LED light bulbs, applied in lighting and heating equipment, cooling/heating devices of lighting devices, outdoor lighting, etc., can solve the problems of high manufacturing cost, incompatibility and difficult maintenance of LED lighting products, and achieve convenience Standardized mass production, high versatility and interchangeability, improving the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

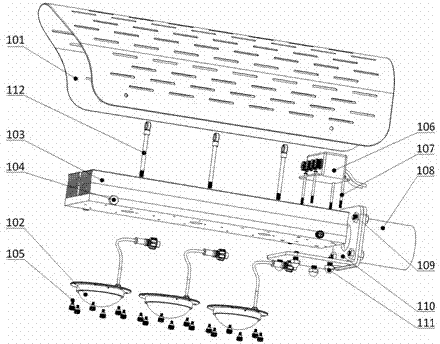

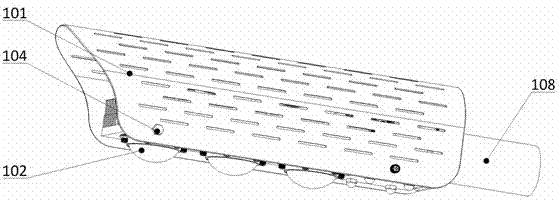

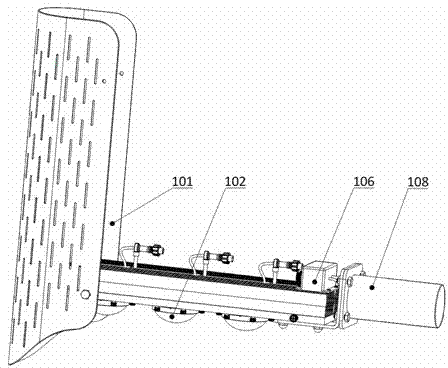

[0063] Example 1. LED street lamps with extruded heat sink structure, such as figure 1 , figure 2 As shown in body 3, it includes an extruded heat sink 103 formed by metal extrusion. The extruded heat sink 103 is provided with an installation interface, and an LED bulb 102 is arranged on the installation interface; the extruded heat sink 103 is installed on the lamp On the rod 108; the extruded heat sink 103 is provided with a lamp housing 101 formed by metal stamping or plastic die-casting; the LED street lamp using the extruded heat sink structure also includes a wire harness connector 106, and the wire harness connector 106 is used for A plurality of LED light bulbs 102 are allocated for access to power and control circuits. The extruded heat sink 103 includes a substrate, and one side of the substrate is provided with fins, such as Figure 4 As shown, the substrate is provided with a cable hole; the other side of the substrate is provided with an installation inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com