LED tunnel lamp using extrusion type double-faced radiator structure

A technology of LED tunnel lights and double-sided radiators, which is applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc. Safety and other issues, to achieve the effect of reducing lighting glare, simple overall structure, and safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

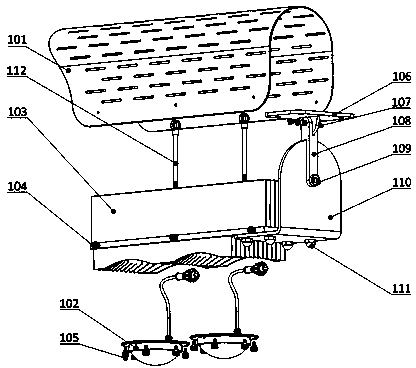

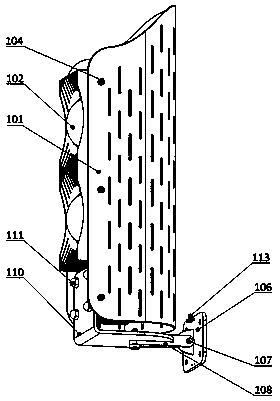

[0065] Example 1. The LED tunnel lamp with extruded double-sided heat sink structure includes a metal extruded double-sided heat The surface radiator 103 is provided with a lamp housing 101 formed by metal stamping or plastic die-casting; 102 installation interface. The extruded double-sided radiator 103 includes a substrate, and fins are provided on both sides of the substrate; one side of the substrate is provided with an installation interface for installing the LED bulb 102, and the fins around the substrate installation interface are cut into circles or The elliptical tapered space is limited to ensure that the light emitted by the LED bulb 102 is not blocked; the other side of the substrate is provided with a wire bracket 112, and the wire bracket 112 is used to connect the lead wires of the LED bulb 102 to the power supply; The surface in contact with the LED light bulb 102 and the hole for connection on the pressure-type double-sided heat sink 103 . The extruded d...

Embodiment 2

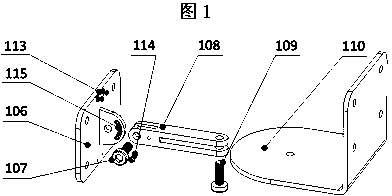

[0071] Example 2. LED tunnel lights with extruded double-sided heat sink structure, such as figure 1 with Figure 28 As shown, it includes a metal extruded double-sided radiator 103 formed by an extrusion process. The extruded double-sided radiator 103 is provided with an LED bulb 102, and the extruded double-sided radiator 103 is equipped with a metal stamping or The lamp housing 101 formed by plastic die-casting; the extruded double-sided radiator 103 is installed on the mounting support 106 , and the extruded double-sided radiator 103 is provided with an installation interface for installing the LED bulb 102 . The extruded double-sided radiator 103 includes a base plate, and both sides of the base plate are provided with fins, such as Figure 31 As shown; one side of the substrate is provided with an installation interface for installing the LED bulb 102, and the fins around the substrate installation interface cut out a circular or elliptical conical space according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com