System and method for runtime determination of camera miscalibration

A calibration error and camera technology, applied in the field of vision systems, can solve the problems of 3D vision system deterioration, the risk of false rejection/false acceptance of camera calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A. Systematic review and calibration

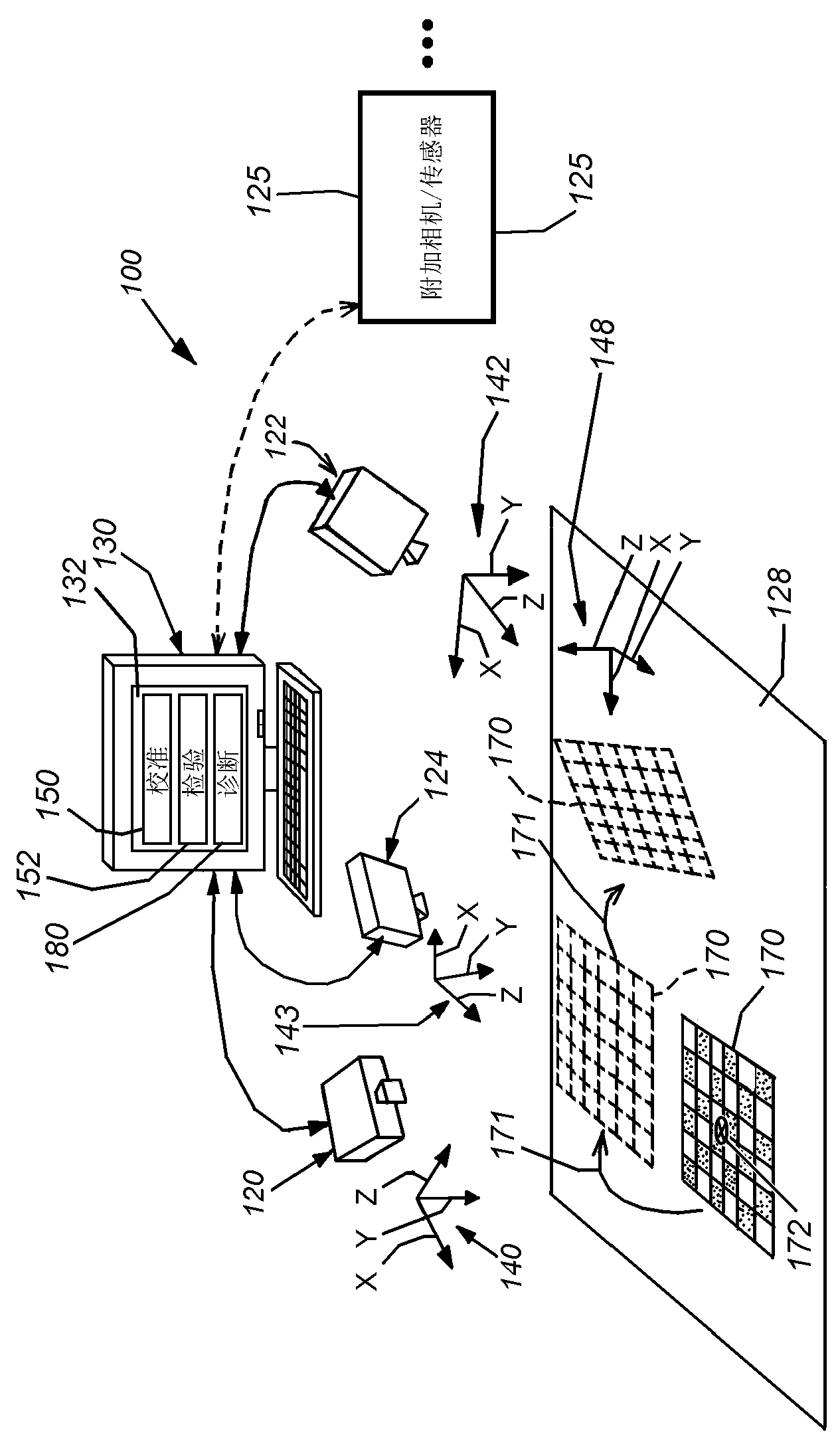

[0022] figure 1 A typical mechanism for a vision system 100 is described to determine the two-dimensional (2D) or three-dimensional (3D) calibration or pose of a viewed scene, which may include one or more A runtime object that controls or assists other operations to inspect, align, and actuate. The system can be calibrated (and the calibration can be followed by self-diagnostics) according to an illustrative embodiment of the present invention.

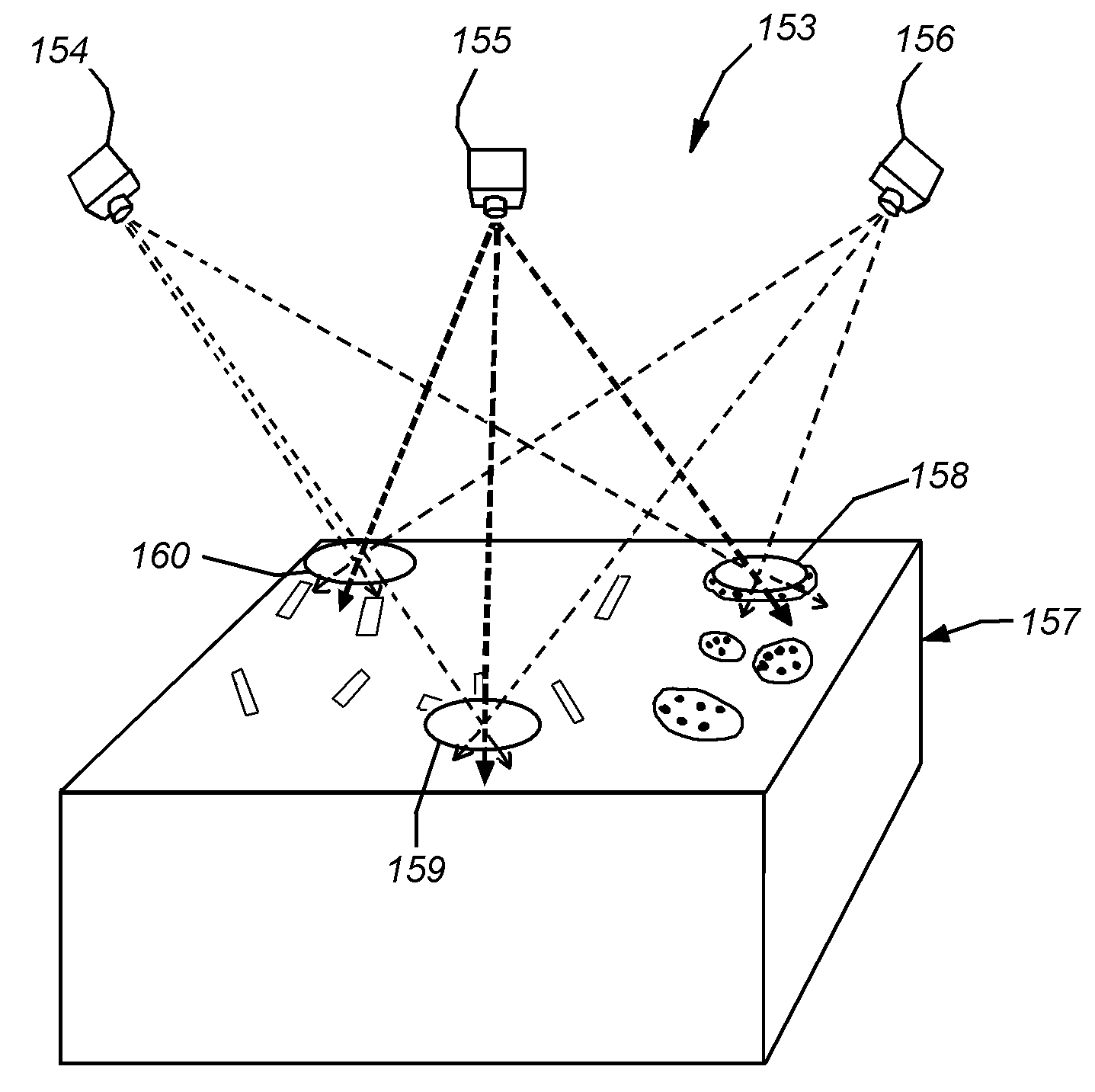

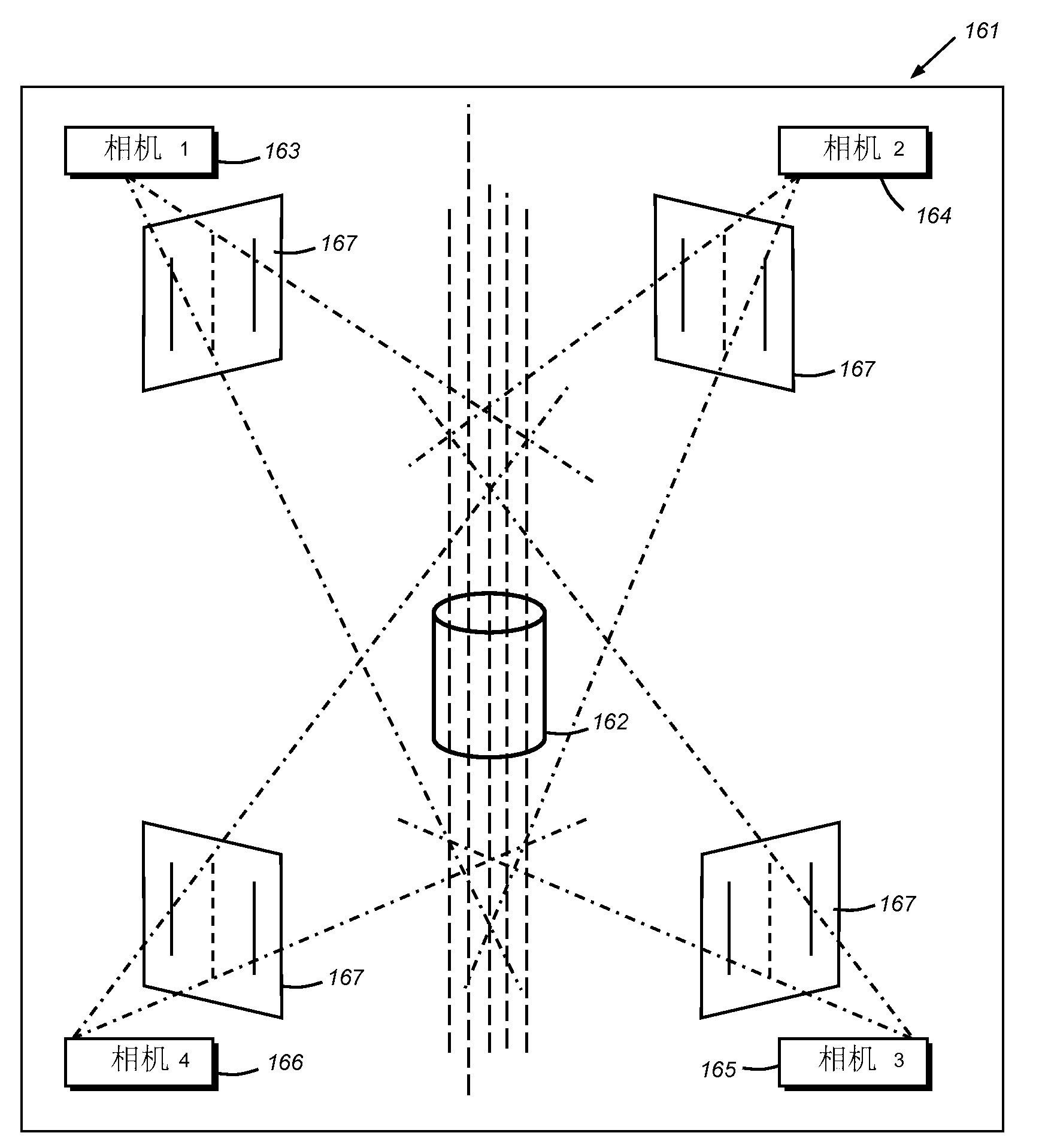

[0023]In general, system 100 may be any vision system mechanism that includes at least three cameras having a scene 128 containing an object within its field of view. The camera(s) or sensor(s) 120, 122, 124 may each comprise a 2D camera as shown, or alternatively, a 3D sensor. When provided, 3D sensor sensors may be adapted to produce a depth image of a scene using optical triangulation within a stereo camera between two discrete cameras (binocular viewing) separated by a known bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com