Interposer testing using dummy connections

An intermediary, electrical connection technology, applied in the field of interconnect components with dummy components, can solve problems such as cost generation and difficulty in effectively testing interposers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The making and using of various embodiments of the invention are discussed in detail below. It should be appreciated, however, that the present invention provides many applicable concepts that can be implemented in a wide variety of specific contexts. The specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

[0038] Structures for testing the reliability of interconnection elements and methods of implementing the tests are provided according to embodiments. Then discusses the variation and implementation process of the embodiment. Like reference numerals refer to like parts throughout the various drawings and embodiments.

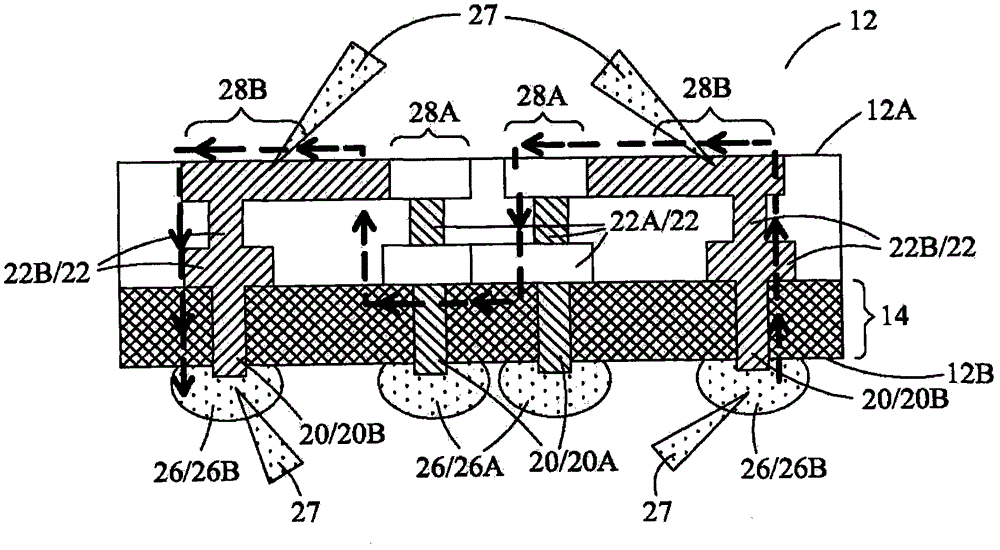

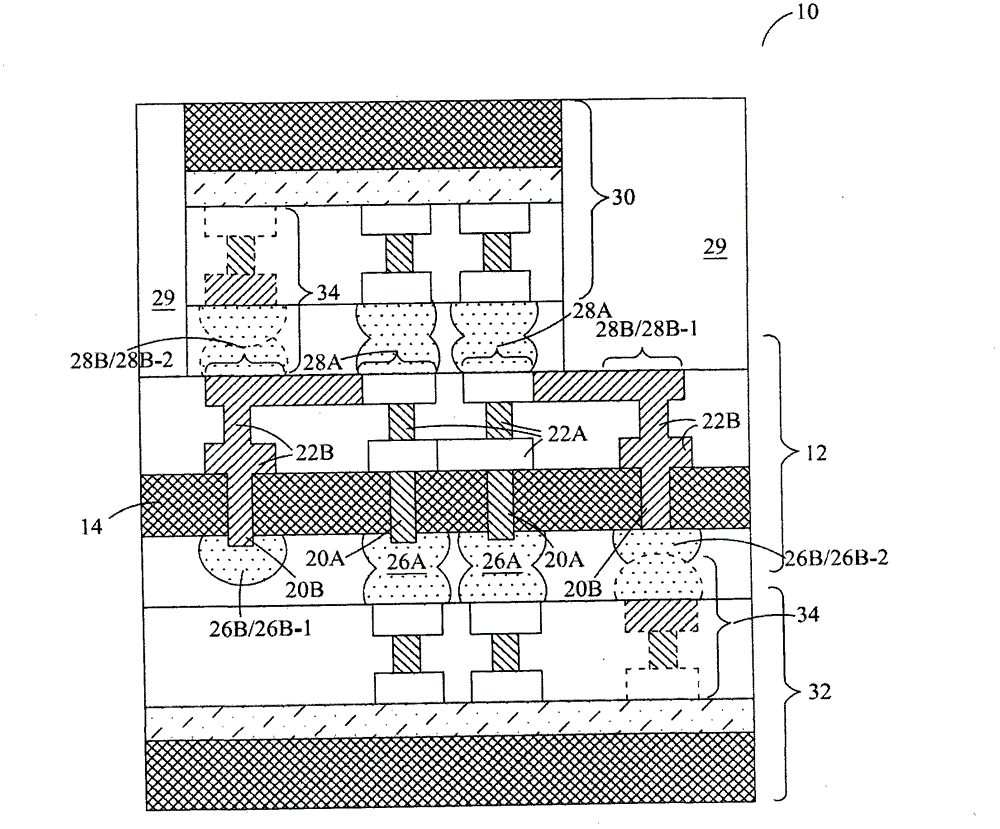

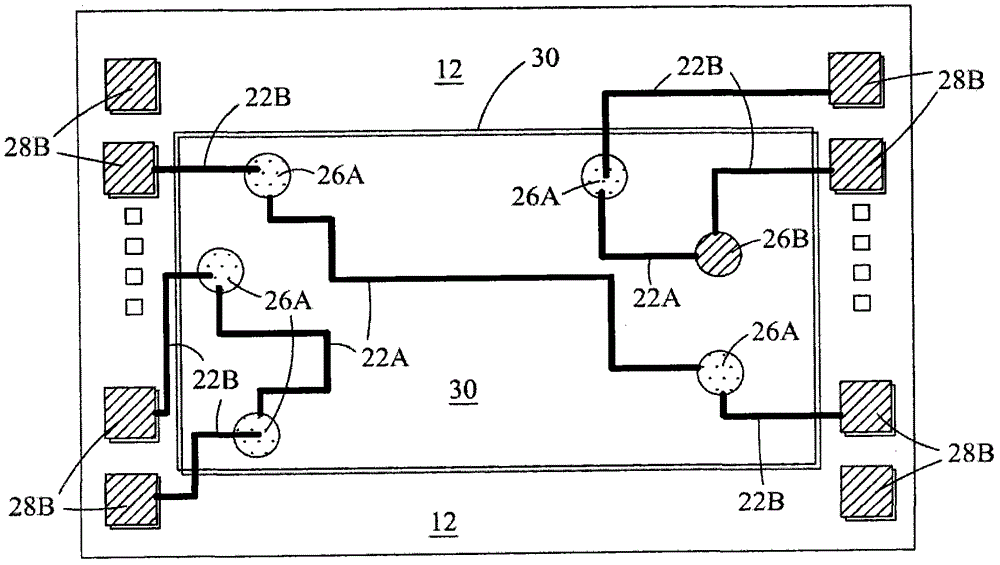

[0039] figure 1 A cross-sectional view of interconnect element 12 is shown configured to form an electrical connection between major surface 12A and major surface 12B, where major surfaces 12A and 12B are opposing surfaces of interconnect element 12 . I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap