Manufacturing method of aero-engine aluminum alloy casing

An aero-engine and manufacturing method technology, which is applied in the field of casting and surface treatment of aero-engine aluminum alloy casing, can solve the problems of inclusions and shrinkage porosity, affecting the qualification rate of castings, low reliability of the casing, etc., so as to avoid time-consuming, Avoid the weight gain of castings and avoid the effect of sulfuric acid anodizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

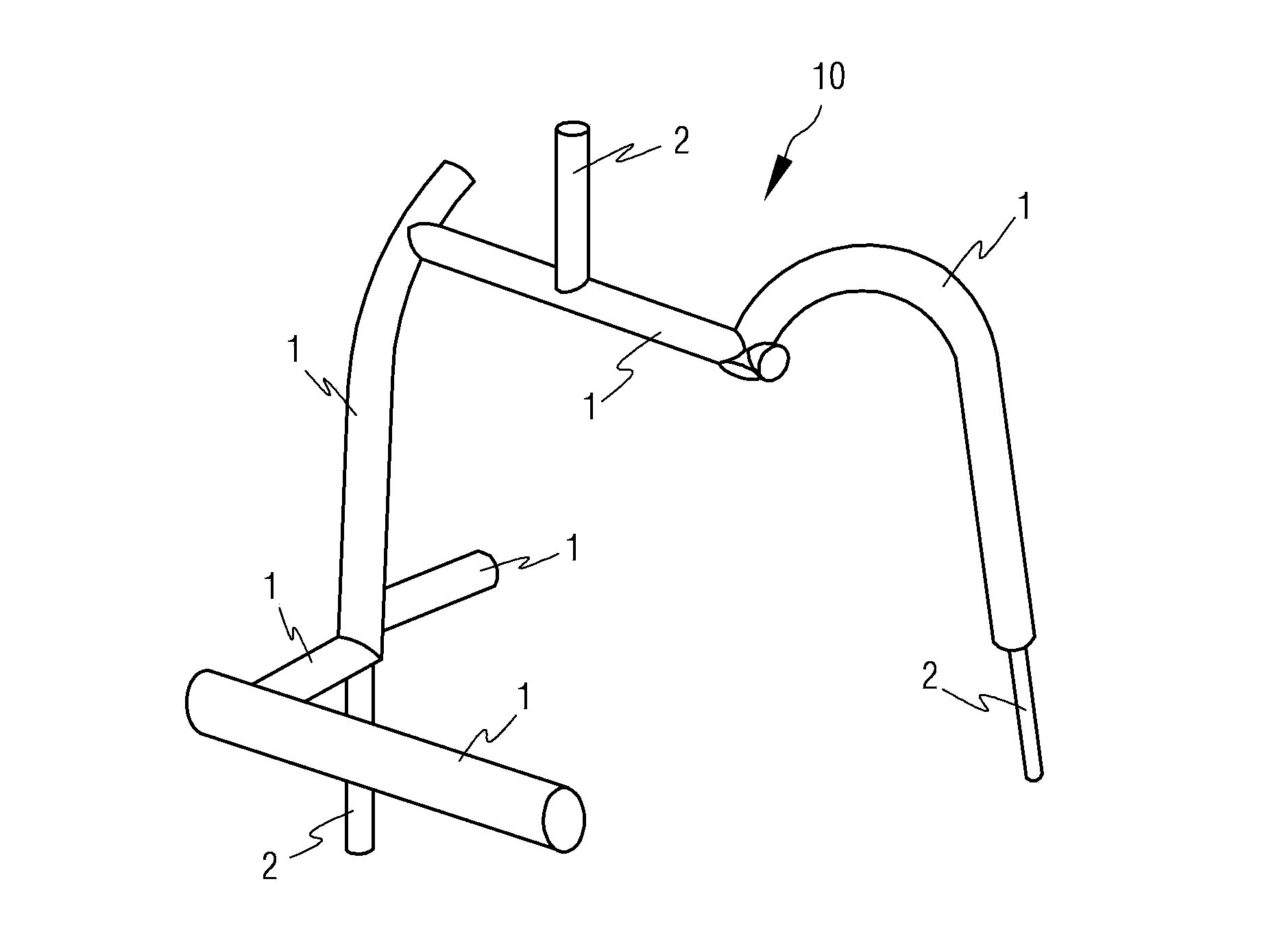

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0024] The invention relates to a method for manufacturing an aviation aluminum alloy casting with complex oil passages, in particular to a casting and surface treatment method for an aluminum alloy casing of an aircraft engine with complicated oil passages. As described in the background technology section of the present invention, the casing is an important part of an aero-engine, and the manufacturing method of the present invention is applicable to any aero-engine casing formed of aluminum alloy in a cast form, and the casing has multiple cooling And the lubricating oil circuit, which can be a whole aluminum alloy casting such as a fan casing, a turbine casing, or an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com