High Pressure Seal Adapter For Splitter Conductor Housing To Wellhead Connection

A high-pressure sealing and adapter technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increasing drilling operation time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

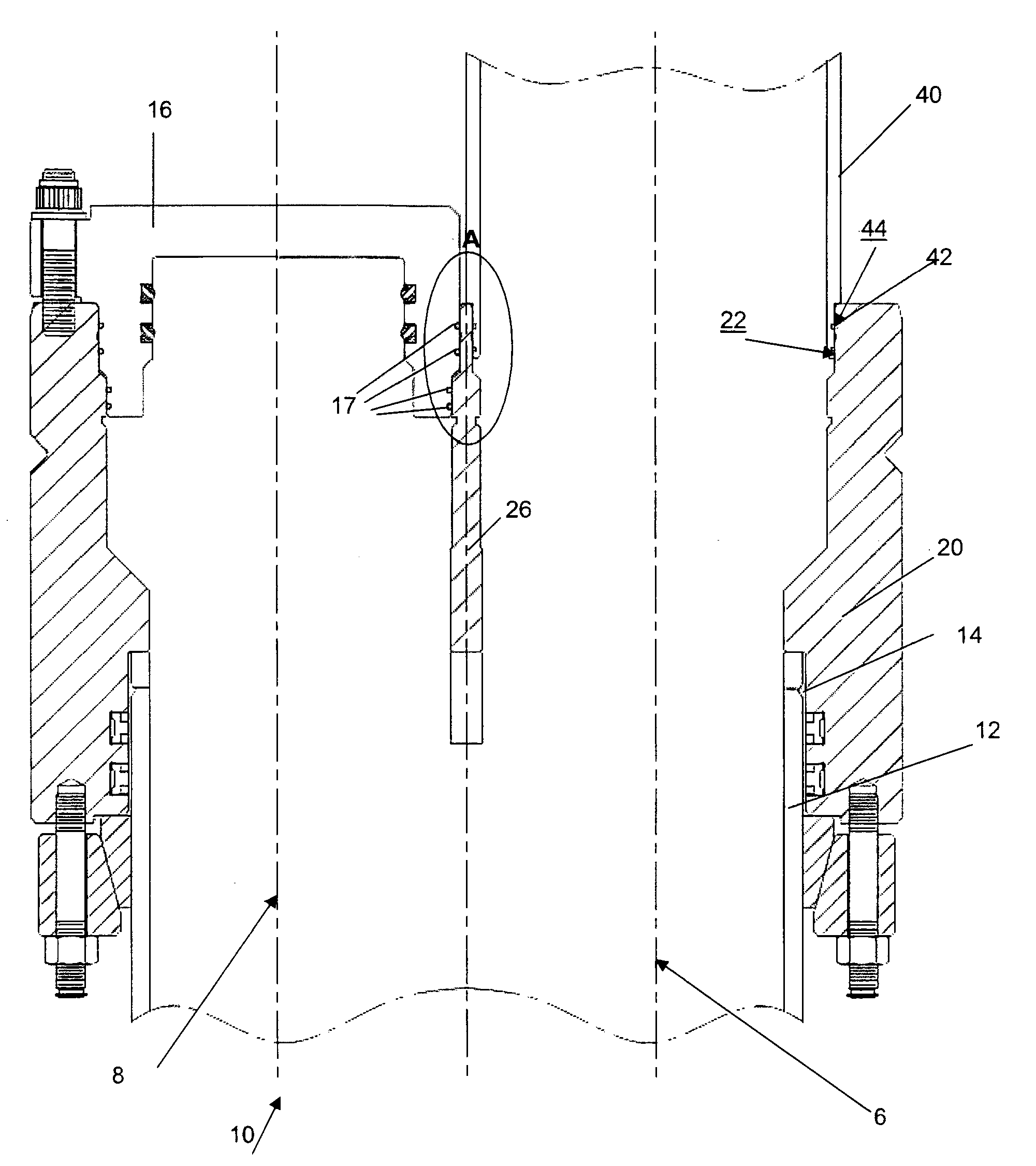

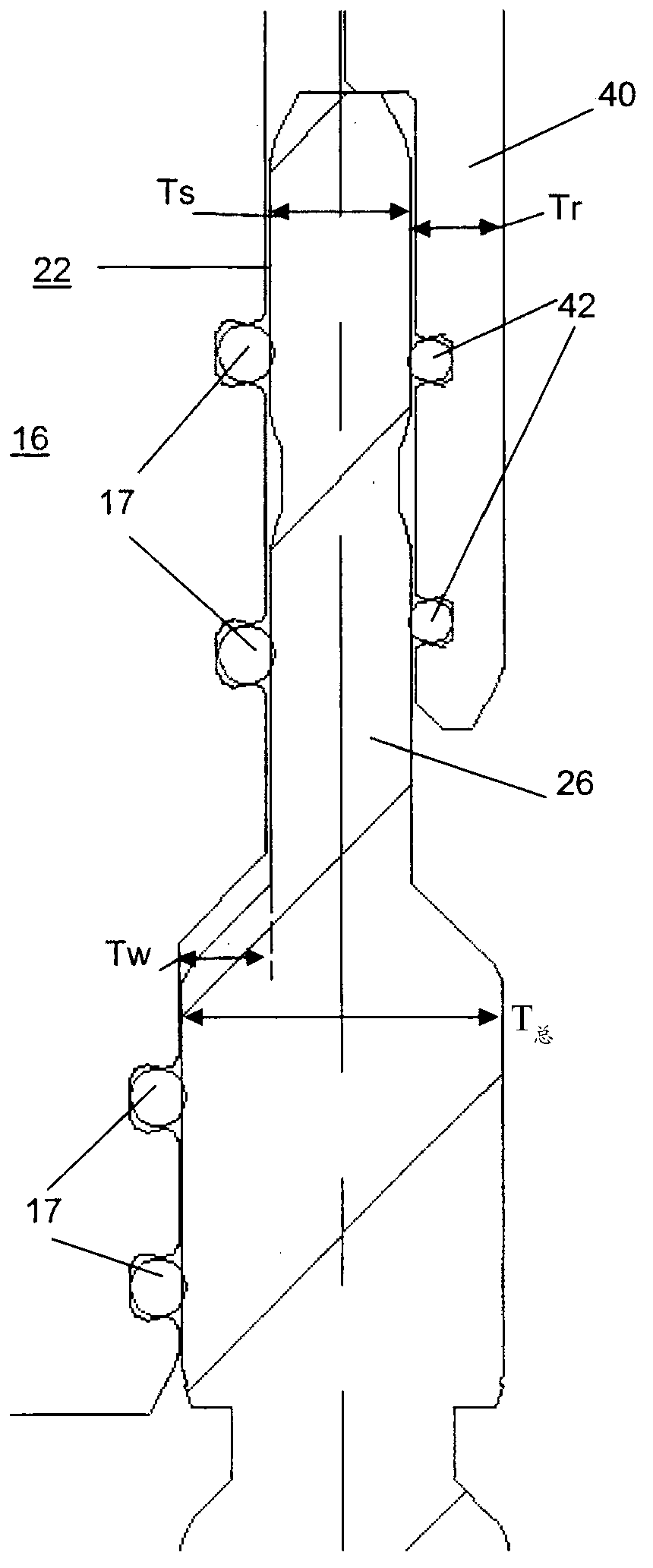

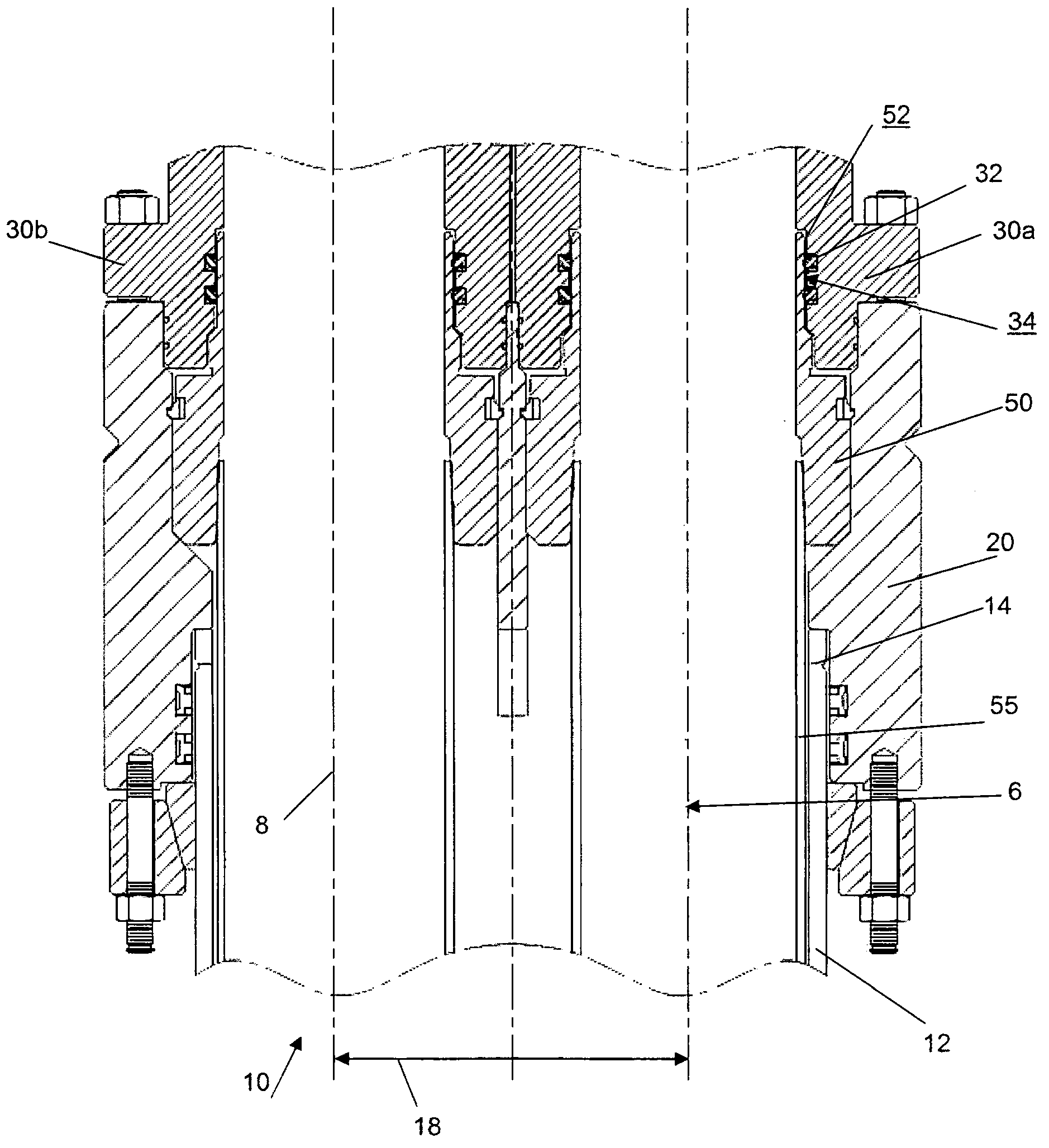

[0034] Embodiments of the present invention provide a separate sealing adapter that can be installed in a modified conduit housing. The seal adapter and improved casing facilitate drilling of the wellbore using standard sized drill bits and allow high pressure operation of the formed well. Exemplary embodiments of the present invention will be discussed below in application using a standard 36 inch (0.9144 meter) conduit with two boreholes. However, it is understood that suitably configured embodiments of the present invention may be used with catheters of any size and having two or more bores.

[0035] Figure 4 A perspective view of one embodiment of a high pressure sealing adapter 100 according to the present invention is shown. Figure 5 show Figure 4 A top view of the high pressure sealing adapter 100 in FIG. Figure 6 show Figure 4 and Figure 5 A side view of the high pressure seal adapter 100 in FIG.

[0036] Seal adapter 100 includes a first aperture 110 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com