System for measuring rotation speed of aviation gasoline engine

A technology of engine speed and measurement system, which is applied to devices using electric/magnetic methods, etc., can solve the problems of inaccurate measurement of probes, affecting the dynamic balance of rotating parts, and inability to embed magnetic materials, and achieves simple speed measurement principle and speed range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

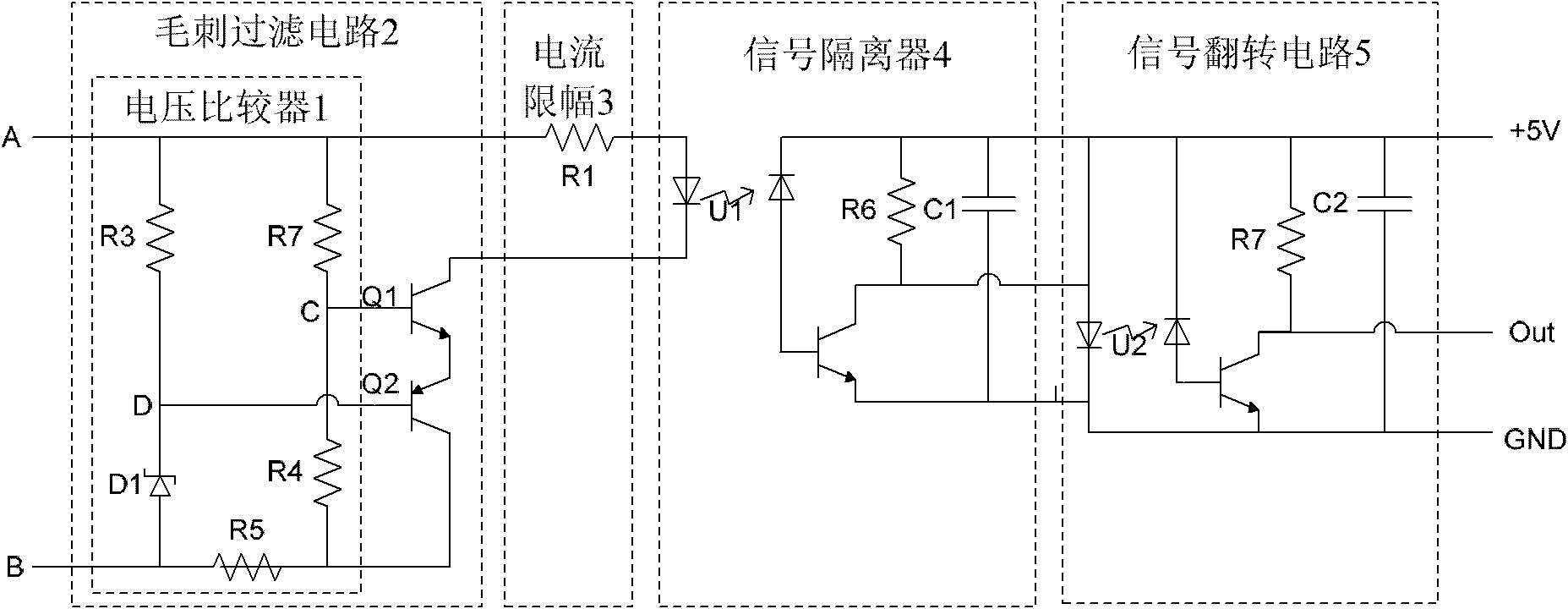

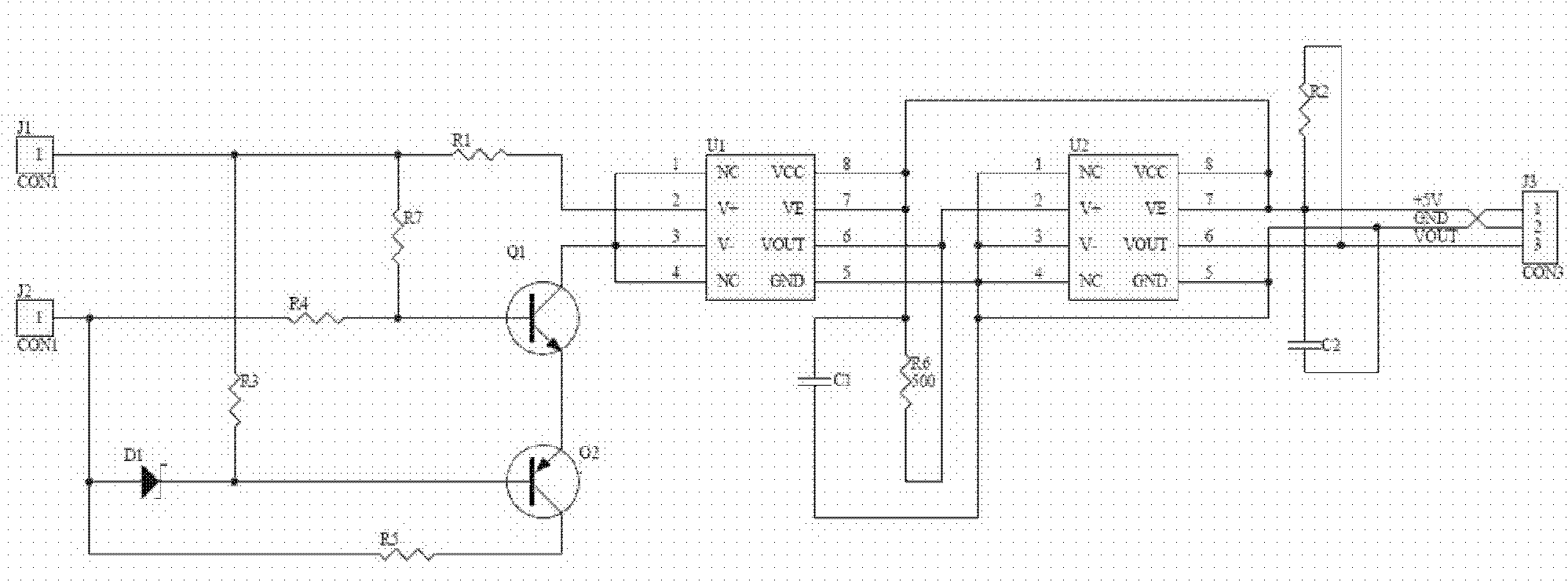

[0017] An aviation gasoline engine speed measurement system, such as figure 1 , 2 shown. Taking the ignition generator of the engine as the signal source, the system includes a glitch filter unit 2 , a current limiting unit 3 , a signal isolation unit 4 and a signal inversion unit 5 .

[0018] The input end of the glitch filtering unit 2 is connected with the ignition generator of the generator, and the output end of the glitch filtering unit 2 is connected with the current limiting unit 3; the input end of the current limiting unit 3 is connected with the glitch filtering unit 2, and the current The output terminal of the limiting unit 3 is connected to the signal isolation unit 4; the input terminal of the signal isolation unit 4 is connected to the current limiting unit 3, and the output terminal of the signal isolation unit 4 is connected to the signal inversion unit 5; the input terminal of the signal inversion unit 5 It is connected with the signal isolation unit 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com