Bottom lifting device for bracket

A technology for moving the frame and moving the frame, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems that the bottom lifting mechanism cannot be installed, the frame is difficult to move, and the space of the support base is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

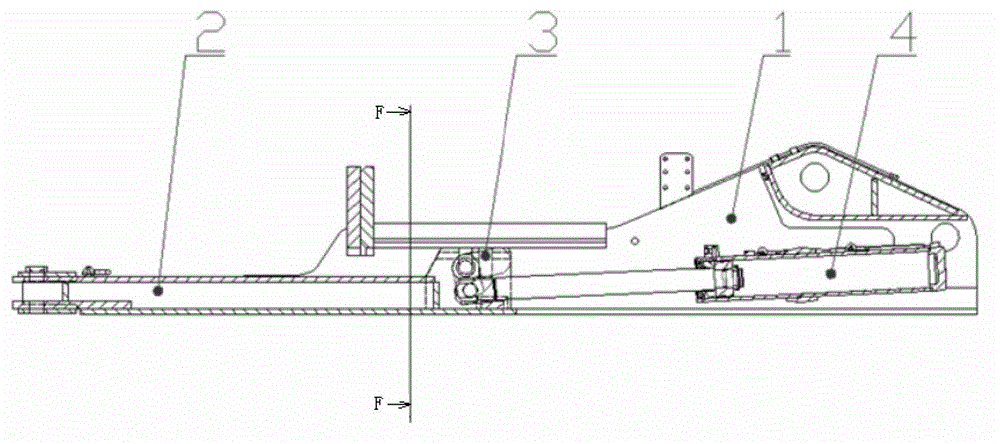

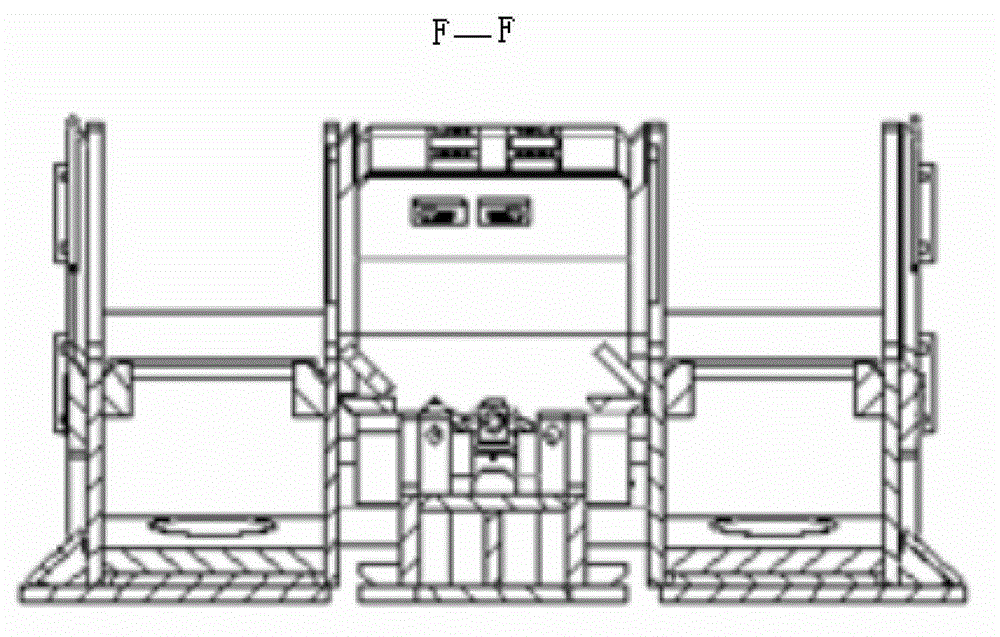

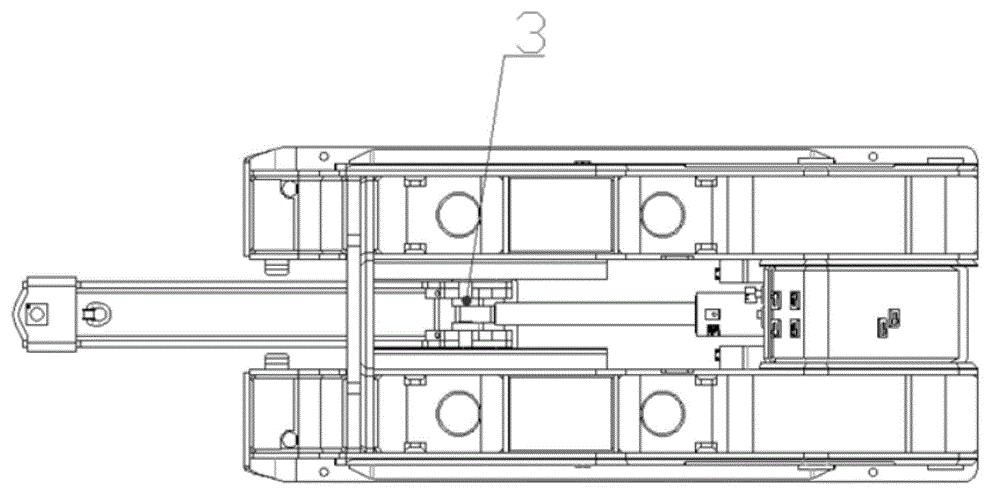

[0018] The bottom lifting device for the bracket provided by the present invention will be described below in conjunction with the embodiments and with reference to the accompanying drawings.

[0019] Such as Figure 1-Figure 7 As shown, the bottom lifting device for the support provided by the embodiment of the present invention includes a base 1 , a moving frame 2 , a rotating part 3 and a moving jack 4 . The rotating component 3 includes a first swing link 6 , a second swing link 7 and a connecting link 5 . Both ends of the connecting rod 5 are connected with the push frame 2, and the connection mode adopted in this embodiment is a movable connection, such as a hinge. The two swing rods are respectively connected to the connecting rod 5 , for example, by tailor welding, and the two connection points are the same point, that is, the two swing rods and the connecting rod 5 intersect at the same point. Of course, the rotating part 3 can also be integrally cast or forged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com