Lag working face end top coal caving hydraulic support

A hydraulic support and working face technology, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as poor safety protection facilities, difficulty in moving frames, and spontaneous combustion of leftover coal, so as to reduce the gangue content rate and solve the problem of moving Difficult to set up and high risk of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

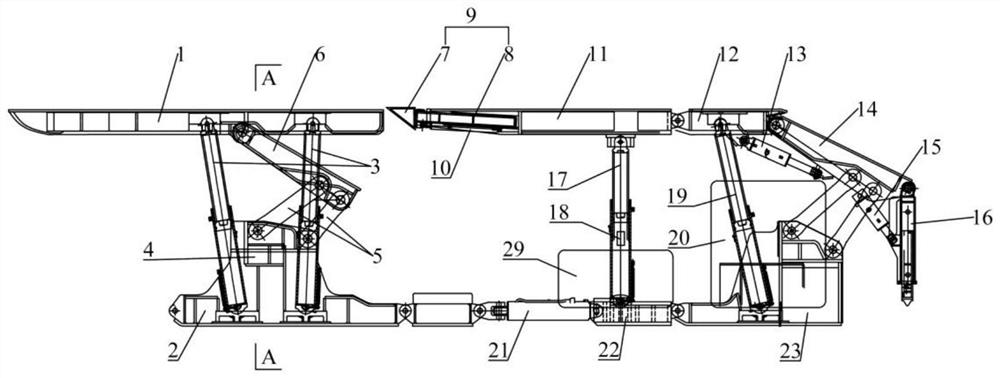

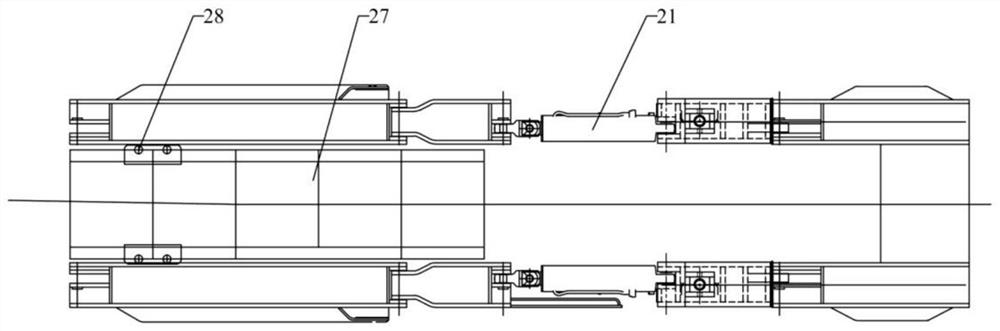

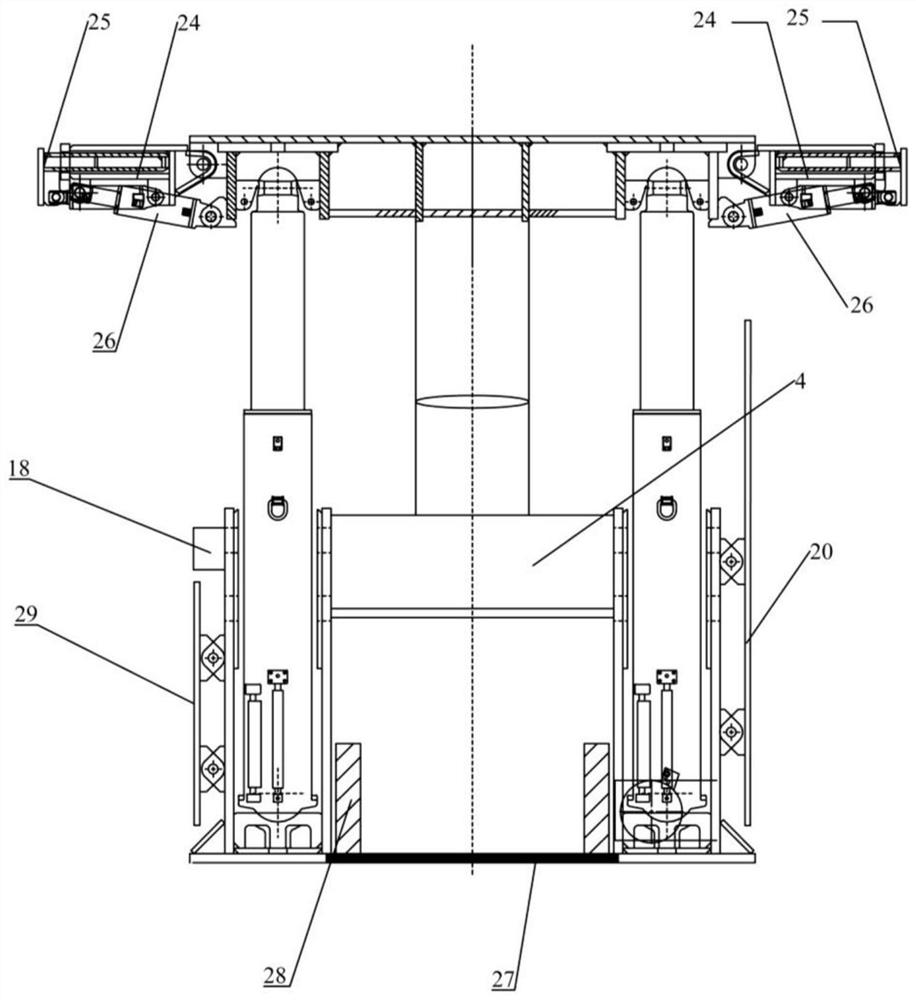

[0019] exist Figure 1 ~ Figure 4 Shown in the figure is a hydraulic support for top coal caving at the end of the present invention, which includes a split front frame and a rear frame. District orientation.

[0020] The front frame includes a first top beam 1 and a first base 2 . A first hydraulic prop 3 and a four-link structure are arranged between the first top beam 1 and the first base 2. The four-link structure is composed of an intermediate platform 4 of the front frame, two connecting rods 5 and a connecting beam 6. The intermediate platform 4. It is rigidly connected with the left and right bases of the front frame, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com