Multi-wire winding method

A winding method and wire technology, which is applied in the field of multi-wire winding, can solve the problems of difficult adjustment of wire gaps and neat winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

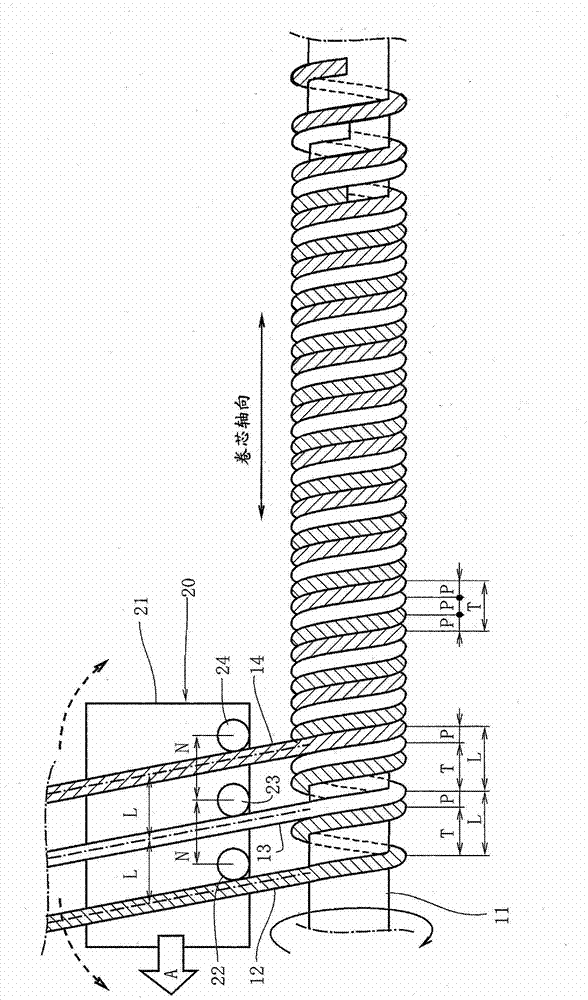

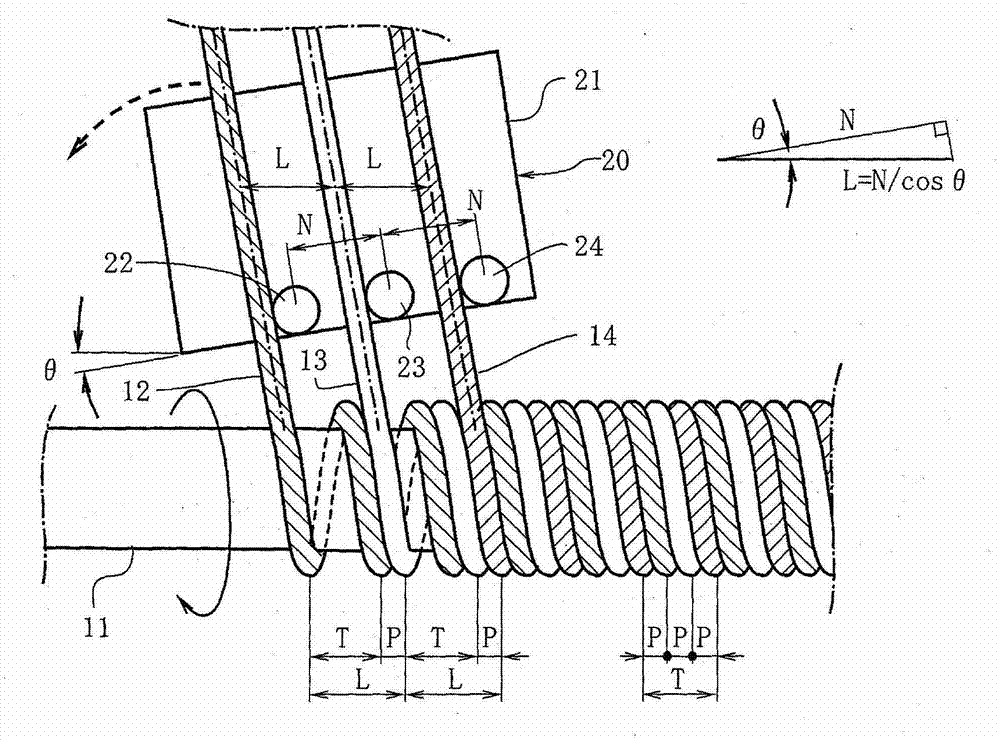

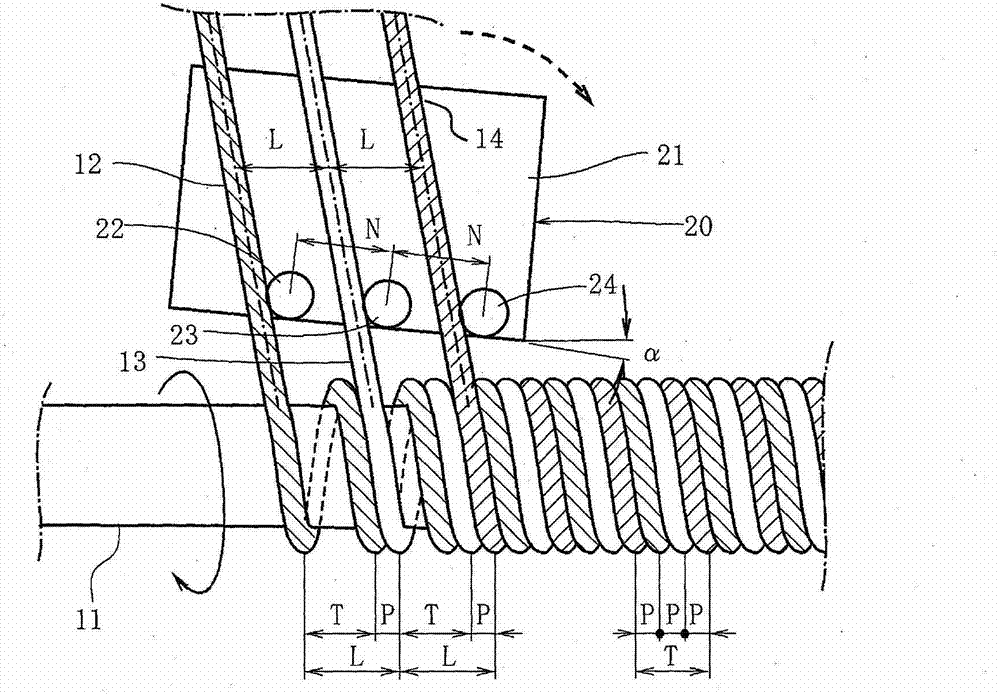

[0021] Next, the best mode for implementing the present invention will be described based on the drawings.

[0022] Such as figure 1 As shown, the multi-wire winding method of the present invention is to wind a plurality of wires 12-14 that are drawn out side by side at a predetermined interval L along the axial direction of the winding core 11 between the central axes of the wires 12-14 on the coil. The outer periphery of the core 11, and the plurality of wires 12-14 that are newly drawn out every time the plurality of wires 12-14 are wound around the winding core 11 move a predetermined amount T along the axial direction of the winding core 11. A winding method in which the wires 12 to 14 are neatly wound around the outer periphery of the winding core 11 .

[0023] as figure 1 The winding core 11 in , shows the case of using a circular cross-section and a long pin or rod-shaped member. In addition, the plurality of wires 12 to 14 are so-called round wires with a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com