Automatic calibration method for optical touch instrument

An automatic calibration and optical touch technology, applied in the input/output process of instruments, data processing, electrical digital data processing, etc., can solve the problems of light power failure, track disconnection, etc., and achieve the effect of solving the track disconnection phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

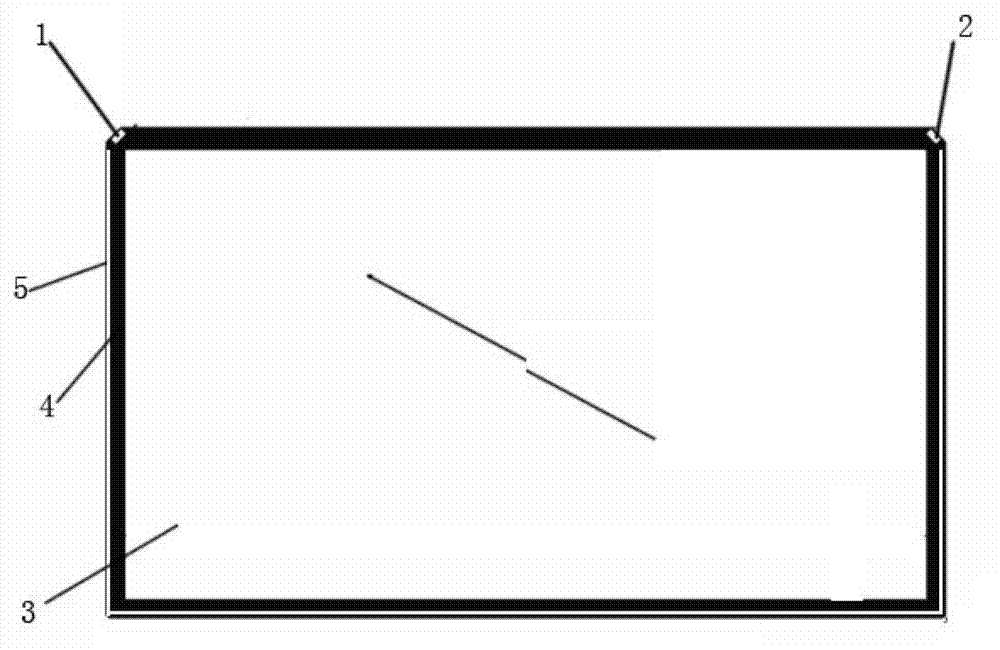

[0015] Such as figure 1 As shown, in the optical touch instrument, the left optical sensor 1 and the right optical sensor 2 emit infrared rays, and a light bar 4 is arranged on the edge of the active area 3, and a glass area 5 is arranged outside the light bar 4, and in the active area In 3, once a hand is touched, its left optical sensor 1 and right optical sensor 2 will respectively obtain a coordinate value, and then in the server, the coordinate value will be directly synthesized to obtain the final coordinate value, when the active area range When it is less, the track disjoint phenomenon is not obvious and cannot be recognized by the naked eye, so this defect can be ignored. However, when the active area increases, the contact track disjoint phenomenon also shows a tendency to enlarge. In general teaching or demonstration optical touch in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com