Combined type sowing fertilizing ditcher

A technology of fertilizing ditch openers and sowing ditching, which is applied in the direction of fertilizer and sowing equipment, etc., which can solve the problems of strong passing capacity, good soil penetration performance of combined openers, and difficult control of soil penetration depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

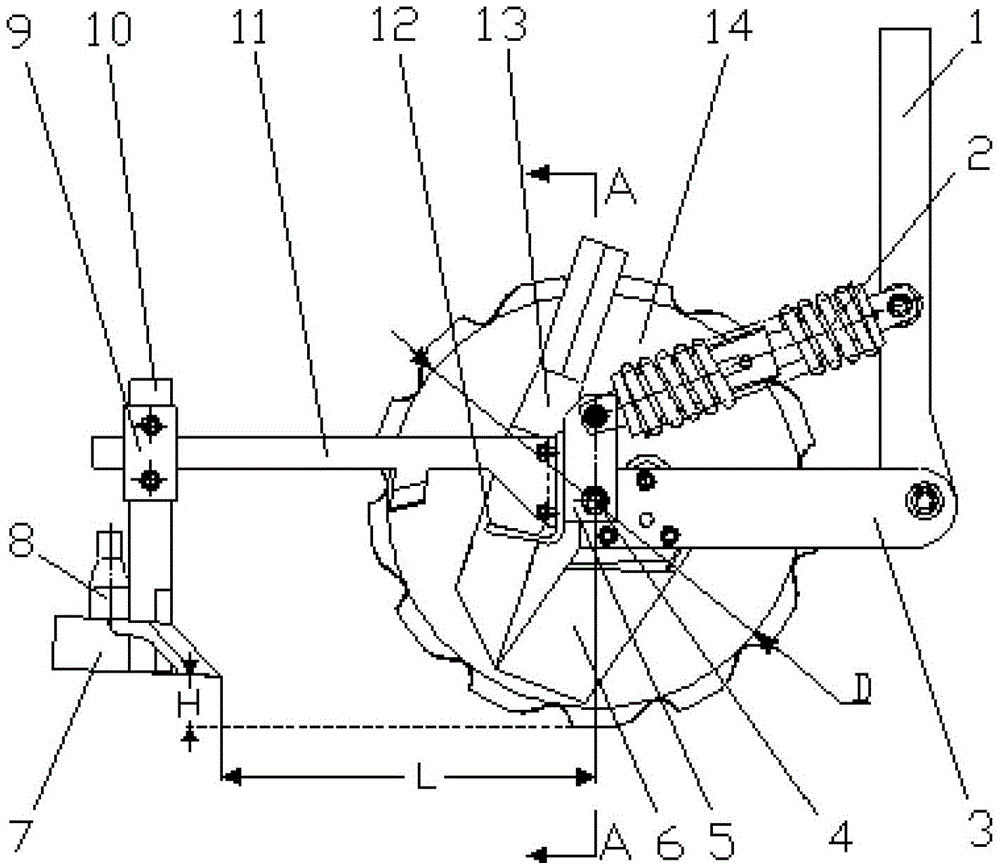

[0026] The specific structure of the present invention will be described below in conjunction with the accompanying drawings.

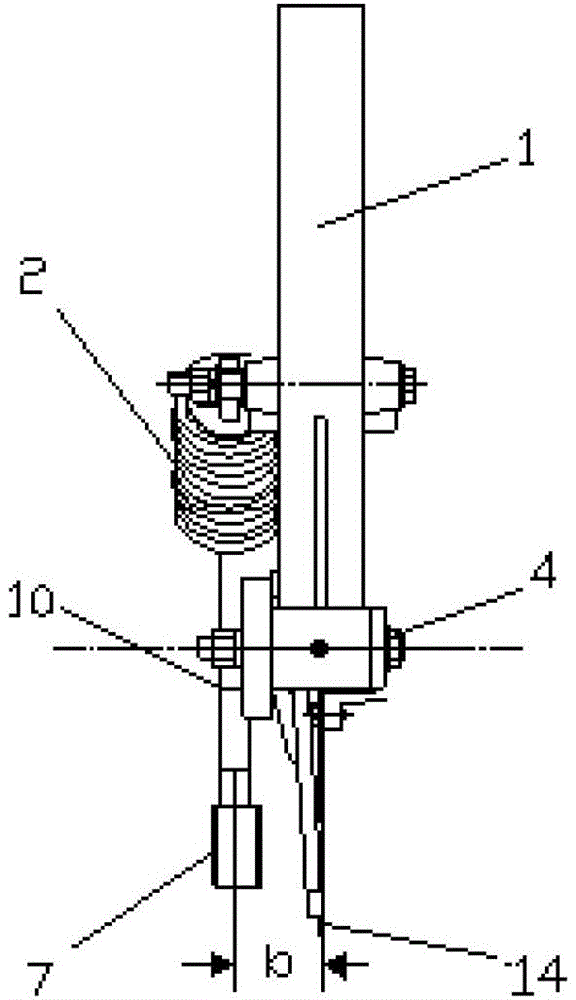

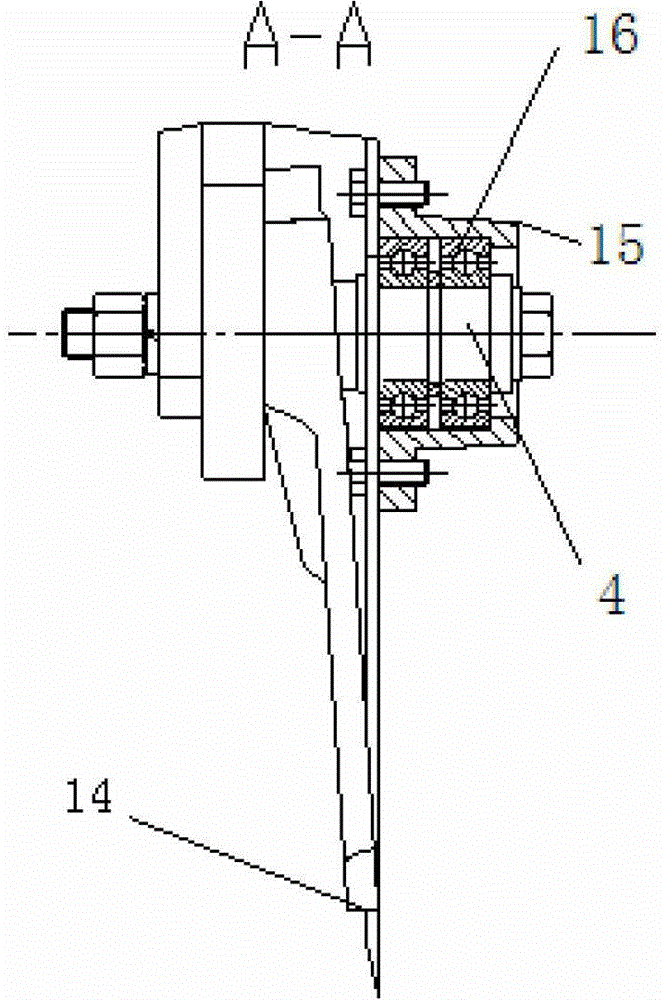

[0027] In this example, if figure 1 The lower end of the shovel handle 1 of the disc opener shown is movably connected with the right end of the pull rod 3 via bolts; the middle part of the shovel handle 1 of the disc opener is connected with the right end of the spring arm 2; the left end of the spring arm 2 is connected with the upper end of the connecting plate seat 5; the connecting plate The lower end of the seat 5 and the left end of the pull rod 3 are fixed on the fertilization shaft 4 at the same time; the right end of the soil scraper 11 and the fertilization pipe connecting curved plate 12 are fixed on the side of the connecting plate seat 5, and the fertilization pipe 13 is fixed on the fertilization pipe connecting curved plate 12; The sowing opener storehouse 10 is fixedly connected to the left end of the moldboard 11; the shovel handle 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com