Elastic pressure relief system for reducing breaker operation work

A technology of operating power and circuit breaker, applied in the direction of high-voltage air circuit breaker, circuit, high-voltage/high-current switch, etc., can solve the problem of reducing the opening speed to zero, reducing the operating power of the circuit breaker, and hindering the opening movement of the circuit breaker.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

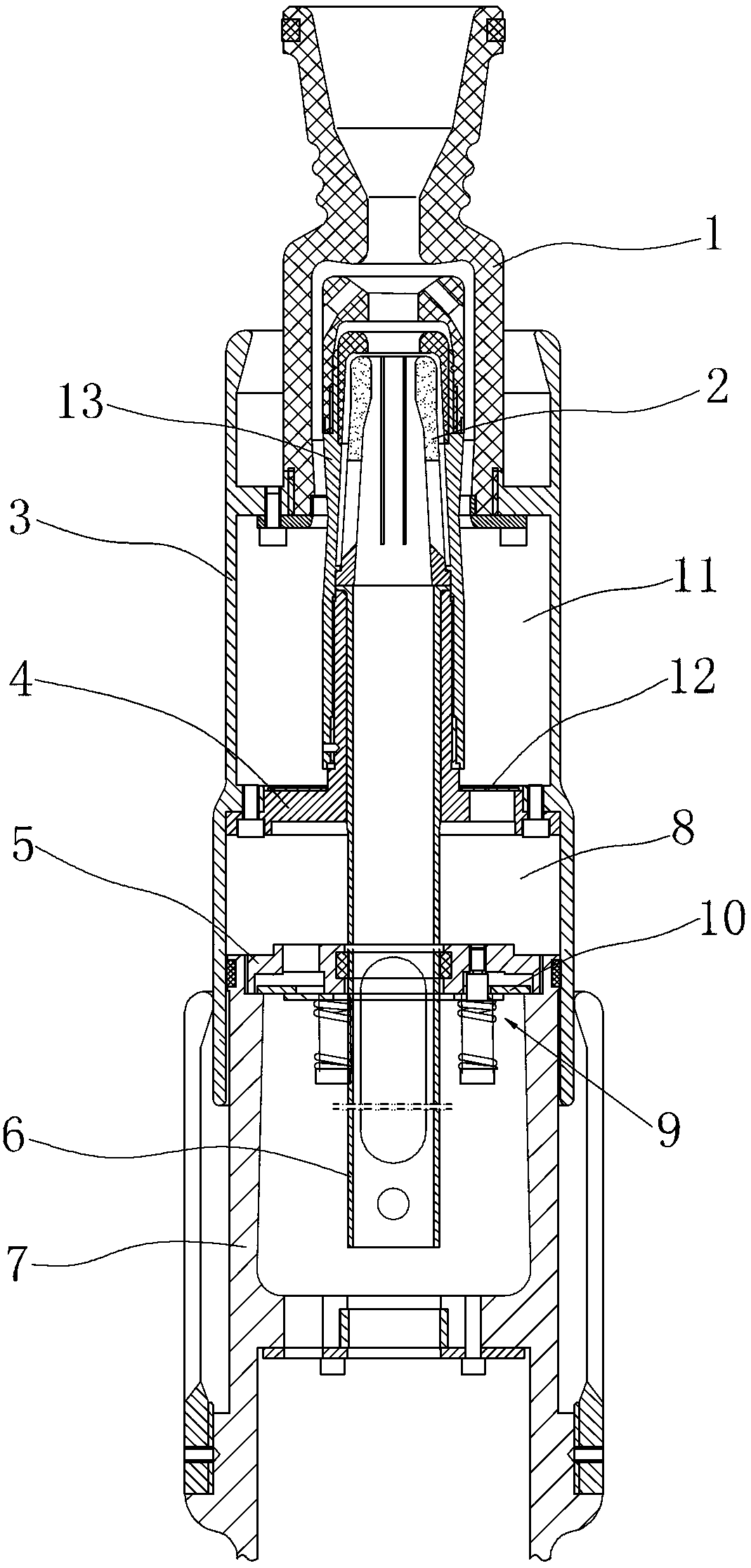

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

[0013] combine figure 1 , The elastic pressure relief system for reducing the operating work of the circuit breaker includes a spout 1, a moving arc contact 2, a cylinder 3, a first flange 4, a second flange 5, a tie rod 6, and a cylinder seat 7. The lower part of the spout 1 is fixed on the upper part of the inner side of the cylinder 3, the upper part of the spout 1 protrudes from the inner side of the cylinder 3, the upper end of the moving arc contact 2 extends into the spout 1, and there is a gap between the moving arc contact 2 and the spout 1, The lower end of the moving arc contact 2 is connected with the inner wall of the cylinder 3 by the first flange 4 . The lower part of the cylinder 3 is set on the cylinder block 7, the upper end cover of the cylinder block 7 has a second flange 5, the tie rod 6 passes through the second flange 5 and is fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com