Compressed-air type arc extinguishing chamber capable of moving bidirectionally

A bi-directional motion and arc extinguishing chamber technology, which is applied in the direction of high-voltage air circuit breakers, electrical components, high-voltage/high-current switches, etc., can solve the problems of redundant mechanical design strength, increased vibration, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

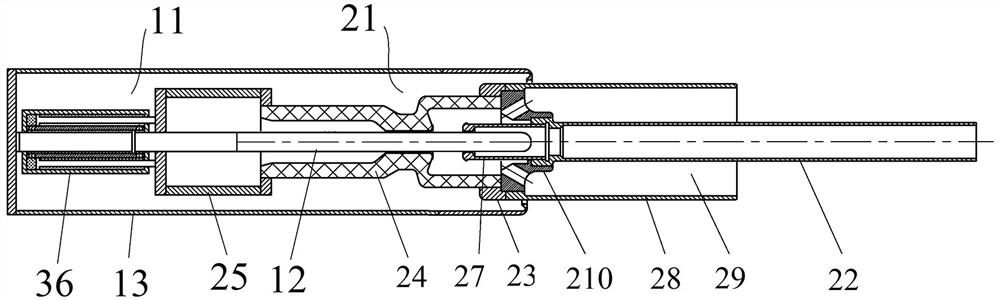

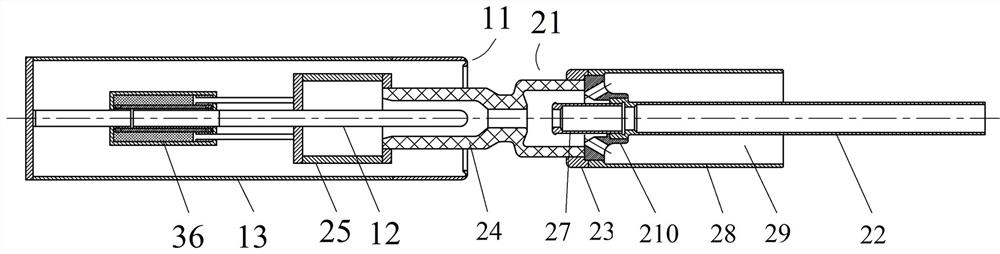

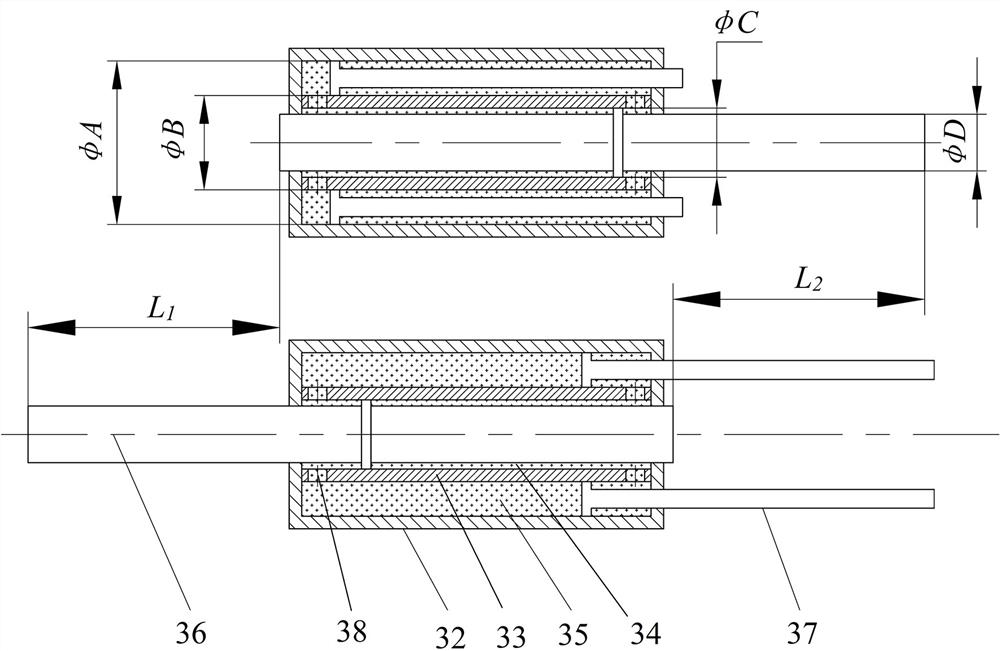

[0045] Such as figure 1 , figure 2 with image 3 As shown, the bidirectionally movable compressed air interrupter includes a static end assembly 11 , a moving end assembly 21 and a double-acting hydraulic cylinder 31 . The static end assembly 11 includes a static arc contact 12, which is guided along the front and rear directions; the moving end assembly 21 includes an insulating pull rod 22, a moving main contact 23, a large nozzle 24, a moving arc contact 27 and a connecting cylinder 25 , also includes the compression cylinder structure, the compression cylinder structure is the same as the prior art, including the compression cylinder 28, the compression cylinder 28 is used to form the compression chamber 29, the compression cylinder 28 is provided with a tie rod connection seat 210, and the tie rod connection seat 210 is used for insulating The pull rod 22 is fixedly connected, and a gas channel is arranged on it for the gas in the compressed gas chamber 29 to be discha...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, radial through holes are provided on the isolation cylinder 33, and the chamber communicating channel 38 is formed by radial through holes, while in this embodiment Among them, the end surfaces of the inner chamber 34 and the outer chamber 35 are provided with communication holes, and the inner chamber 34 and the outer chamber 35 are communicated through a pipeline connected between the two communication holes.

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the isolation cylinder 33 directly separates the inner chamber 34 and the outer chamber 35, while in this embodiment, the inner chamber 34 and the outer chamber An annular cavity is provided between the chambers 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com