Pressure-sensitive adhesive composition and pressure sensitive adhesive tape

A composition and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, graft polymer adhesives, etc., can solve the problems of insufficient temperature-sensitive adhesiveness and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

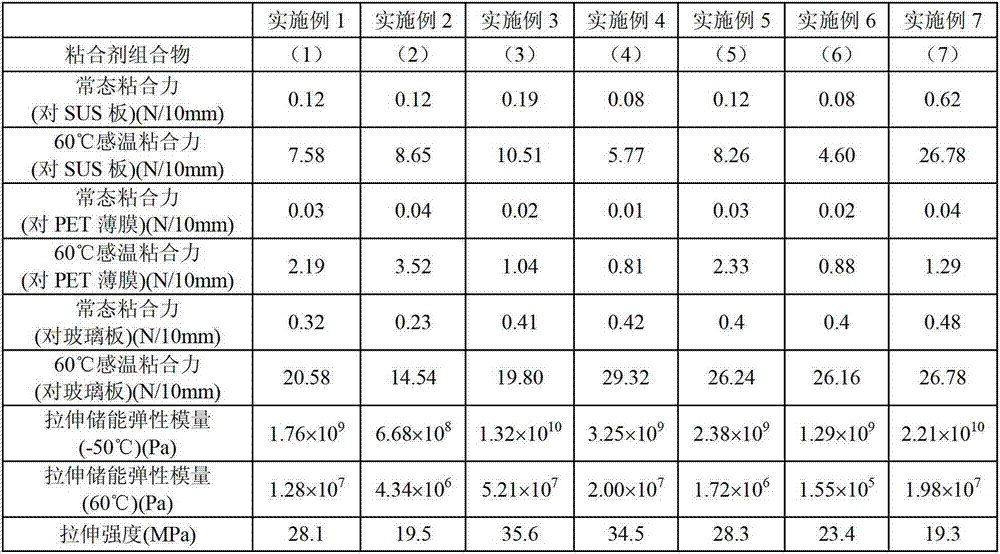

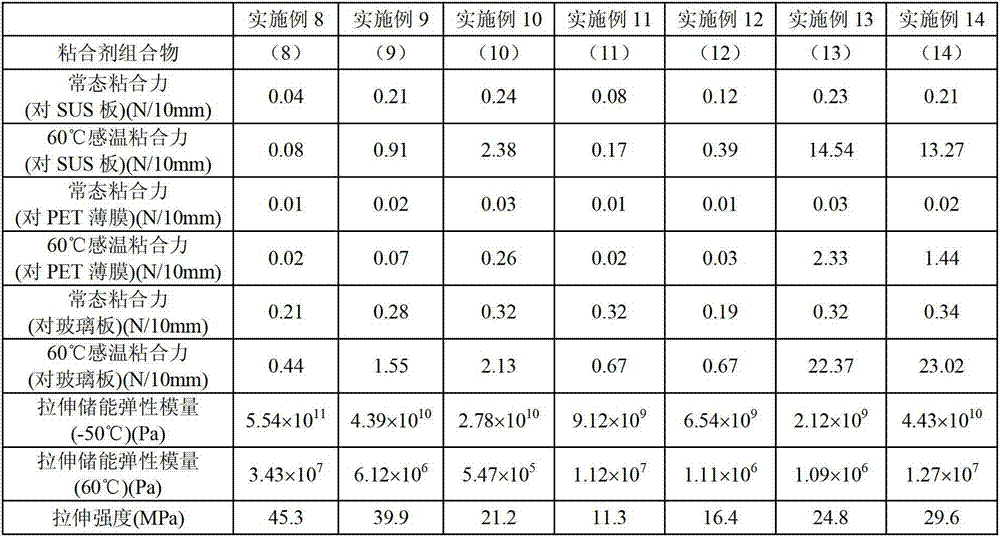

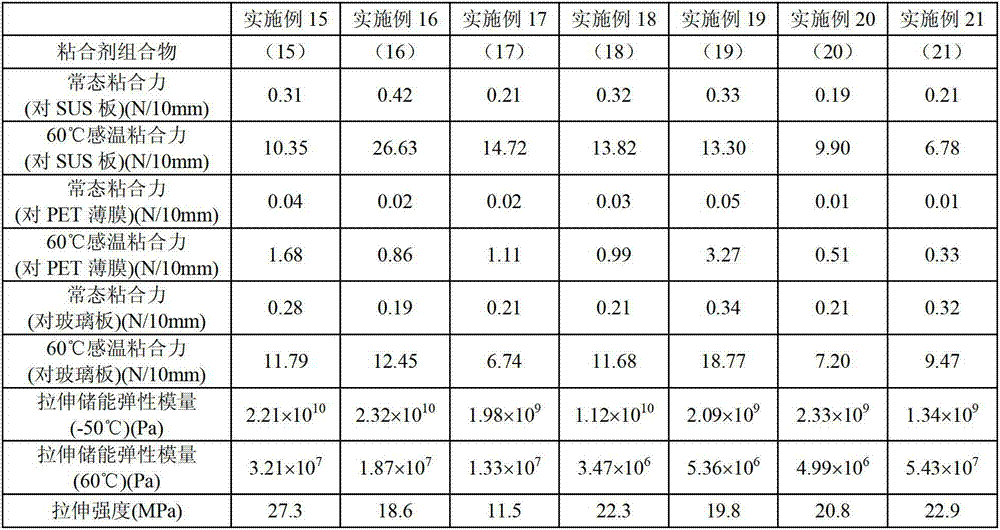

Examples

Embodiment 1

[0094] To a mixture of 42.50 g of methyl acrylate, 5.00 g of N,N-dimethylacrylamide, and 2.50 g of acrylic acid, add 38.44 g of polycarbonate diol (Nitsupolan 981, Mw=1000, manufactured by Nippon Polyurethane Industry Co., Ltd.) and 9.33 g of hydrogenated xylene diisocyanate (Tahine 1 to 650, manufactured by Takeda Pharmaceutical Co., Ltd.), were heated and stirred at 65° C. under a nitrogen atmosphere for more than 4 hours. While maintaining this state, 2.23 g of 2-hydroxyethyl acrylate was added, followed by heating and stirring for 1 hour or more. 1.00 g of a photopolymerization initiator (IRGACURE651, manufactured by BASF Corporation) was added to the obtained viscous liquid, coated on a polyester release liner to a thickness of 50 μm, and then irradiated with ultraviolet rays for 1 minute (light source: metal halide lamp), An adhesive composition (1) having a thickness of 50 μm was obtained.

[0095] The molar ratio of the polycarbonate diol to the hydrogenated xylene di...

Embodiment 2

[0100] Change the usage-amount of polycarbonate diol into 40.43g, the usage-amount of hydrogenated xylene diisocyanate becomes 8.63g, the usage-amount of acrylate-2-hydroxyethyl ester becomes 0.94g, except that, carry out similarly with embodiment 1, An adhesive composition (2) having a thickness of 50 μm was obtained.

[0101] The molar ratio of the polycarbonate diol to the hydrogenated xylene diisocyanate is 0.081 mol:0.089 mol=1:1.1.

[0102] The molar ratio of the polycarbonate diol to the 2-hydroxyethyl acrylate is 0.081 mol:0.008 mol=1:0.1.

[0103] The adhesive composition (2) is formed by crosslinking the polymer skeleton (a) derived from the acrylic copolymer (A) through the polymer skeleton (b) derived from the urethane (meth)acrylate (B) The adhesive composition of the obtained cross-linked polymer, the content ratio of the polymer skeleton (a) to the polymer skeleton (b) in the cross-linked polymer structure, in terms of weight ratio, (a): (b) =50.00g:50.00g=50:...

Embodiment 3

[0106]Change the usage-amount of polycarbonate diol into 36.64g, the usage-amount of hydrogenated xylene diisocyanate becomes 9.96g, the usage-amount of acrylate-2-hydroxyethyl ester becomes 3.40g, except that, carry out similarly with embodiment 1, An adhesive composition (3) having a thickness of 50 μm was obtained.

[0107] The molar ratio of the polycarbonate diol to the hydrogenated xylene diisocyanate is 0.073 mol:0.103 mol=1:1.4.

[0108] The molar ratio of the polycarbonate diol to the 2-hydroxyethyl acrylate is 0.073 mol:0.029 mol=1:0.4.

[0109] The adhesive composition (3) is formed by cross-linking the polymer skeleton (a) derived from the acrylic copolymer (A) through the polymer skeleton (b) derived from the urethane (meth)acrylate (B) The adhesive composition of the obtained cross-linked polymer, the content ratio of the polymer skeleton (a) to the polymer skeleton (b) in the cross-linked polymer structure, in terms of weight ratio, (a): (b) =50.00g:50.00g=50:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap